Large-diameter underground gas drainage pipeline system construction method

A gas drainage and pipeline system technology, which is used in gas discharge, earth-moving drilling, pipeline laying and maintenance, etc., and can solve problems such as gas pipeline suspension construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

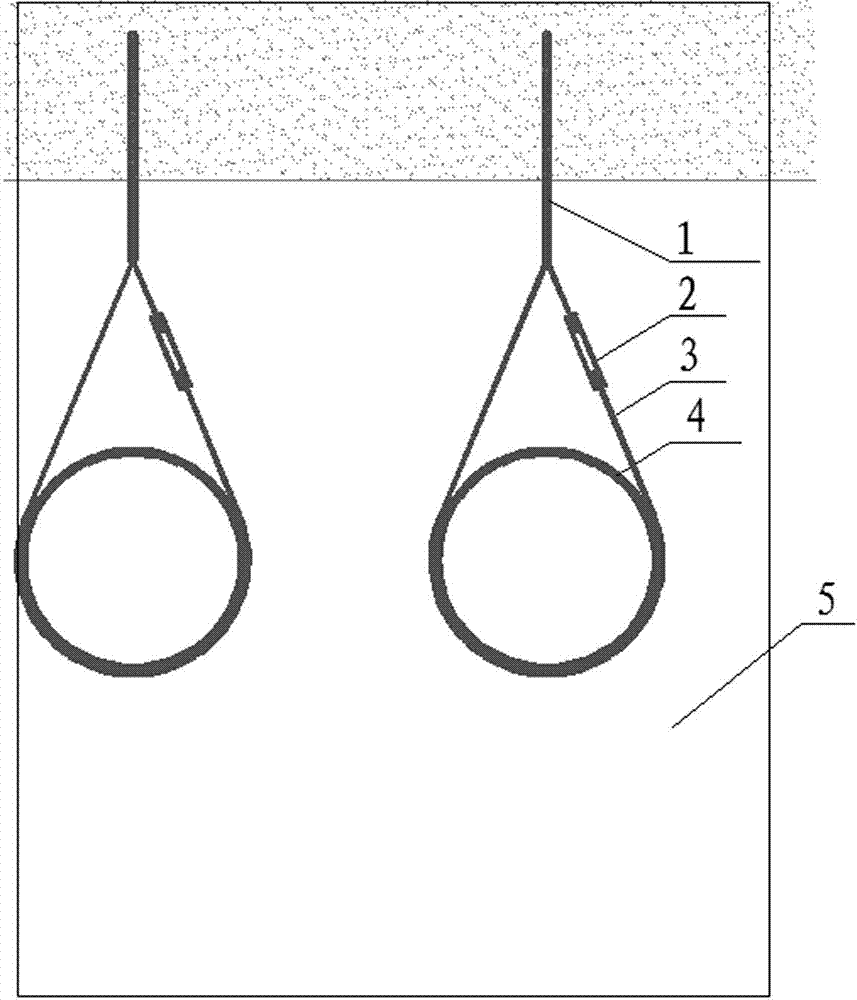

[0020] A large-diameter underground gas drainage pipeline system construction method,

[0021] 1 measurement set-out

[0022] Before the construction of the bolt and anchor cable, it is necessary to measure and set out the line according to the design. Before the line is set out, the specific position of the pipeline is determined according to the design requirements, and then the line is set out according to the baseline given by the mine. When laying out the line, based on the reference line and the intersection point of the two crossing reference lines, use the cross point of the laser line thrower to align with the intersection point of the reference line and make the two cross lines overlap with the crossing reference line, and then use a tape measure to measure at the top of the roadway And locate the intersection of the pipes. Use this intersection point to cooperate with the laser line thrower, mine straightness meter, and engineering wire rope to set out the line. Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com