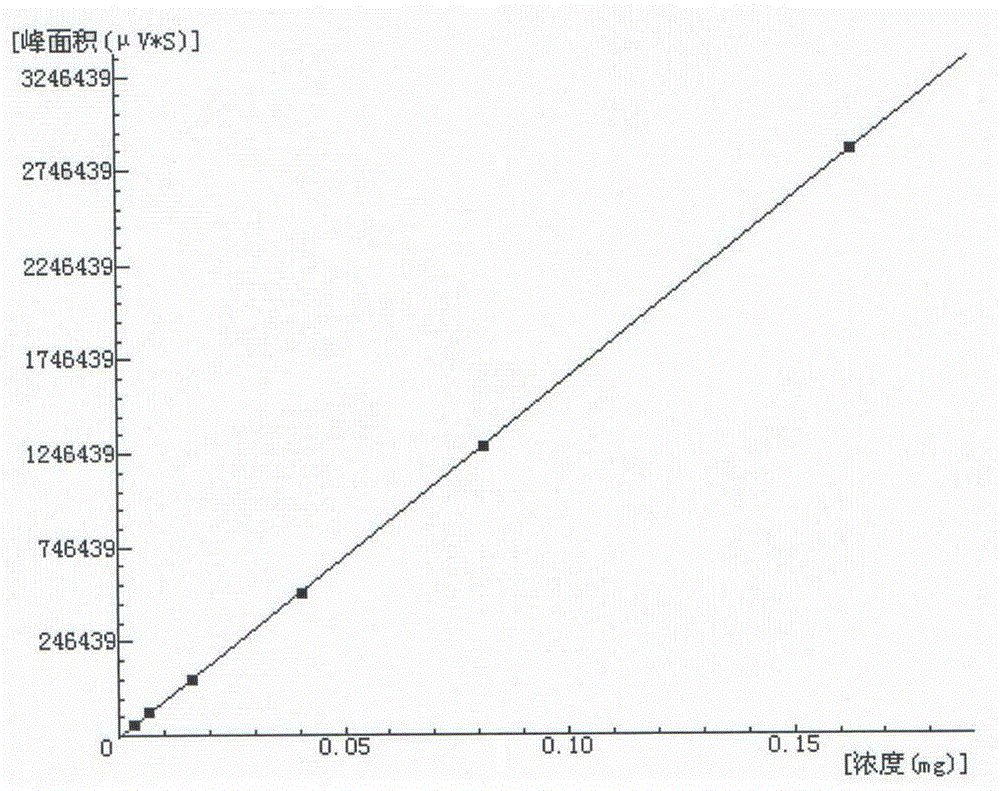

Method for detecting polyaspartic acid in polypeptide urea by high-performance liquid chromatography

A technology of high performance liquid chromatography and polyaspartic acid, applied in the direction of measuring devices, instruments, scientific instruments, etc., to achieve the effect of reliable detection data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

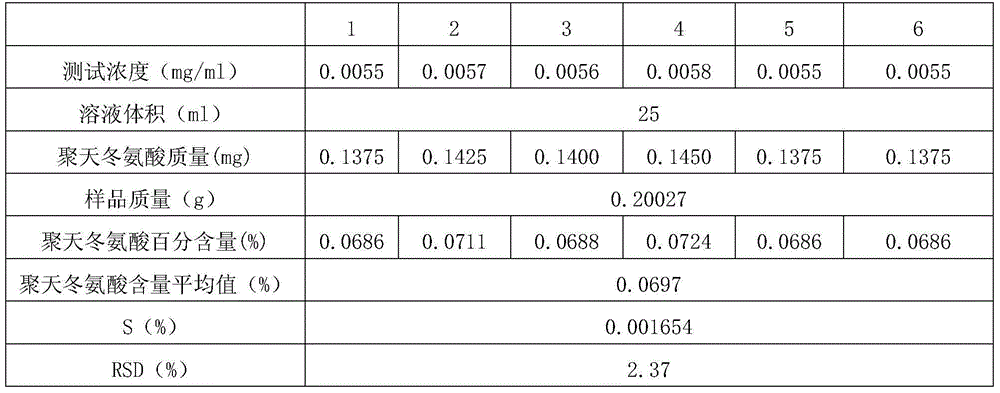

Examples

Embodiment

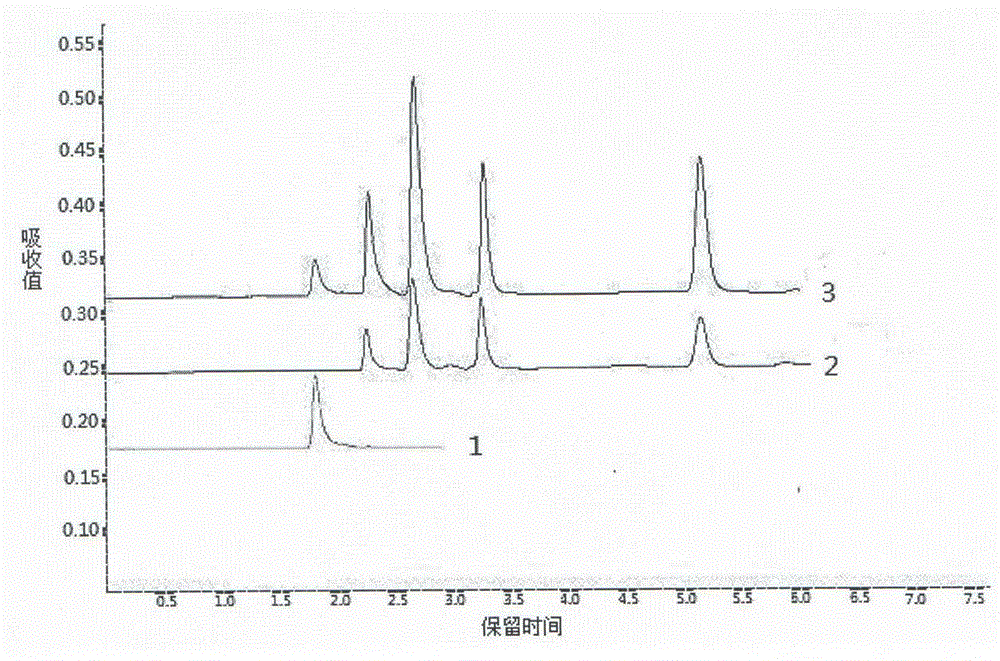

[0019] The method for detecting polyaspartic acid in polypeptide urea by high performance liquid chromatography, the high performance liquid chromatography condition in this method is:

[0020] Chromatographic column: C18, 5μm, 250×4.6mm (I.D.);

[0021] Column temperature: room temperature;

[0022] Mobile phase composition: volume ratio methanol: water = 6:94, water is double distilled water, add 0.04% volume percentage triethylamine;

[0023] Mobile phase pH: adjusted to pH9.5 with dilute phosphoric acid 1:10;

[0024] Mobile phase velocity: flow rate 0.7ml / min;

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com