Online analysis system and method for detection of CO gas at ammonia synthesis inlet

A gas detection and analysis system technology, which is applied in the direction of analyzing materials, material analysis by optical means, measuring devices, etc., can solve the problems of high error and inability to monitor in real time, and achieve the effect of online detection and analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

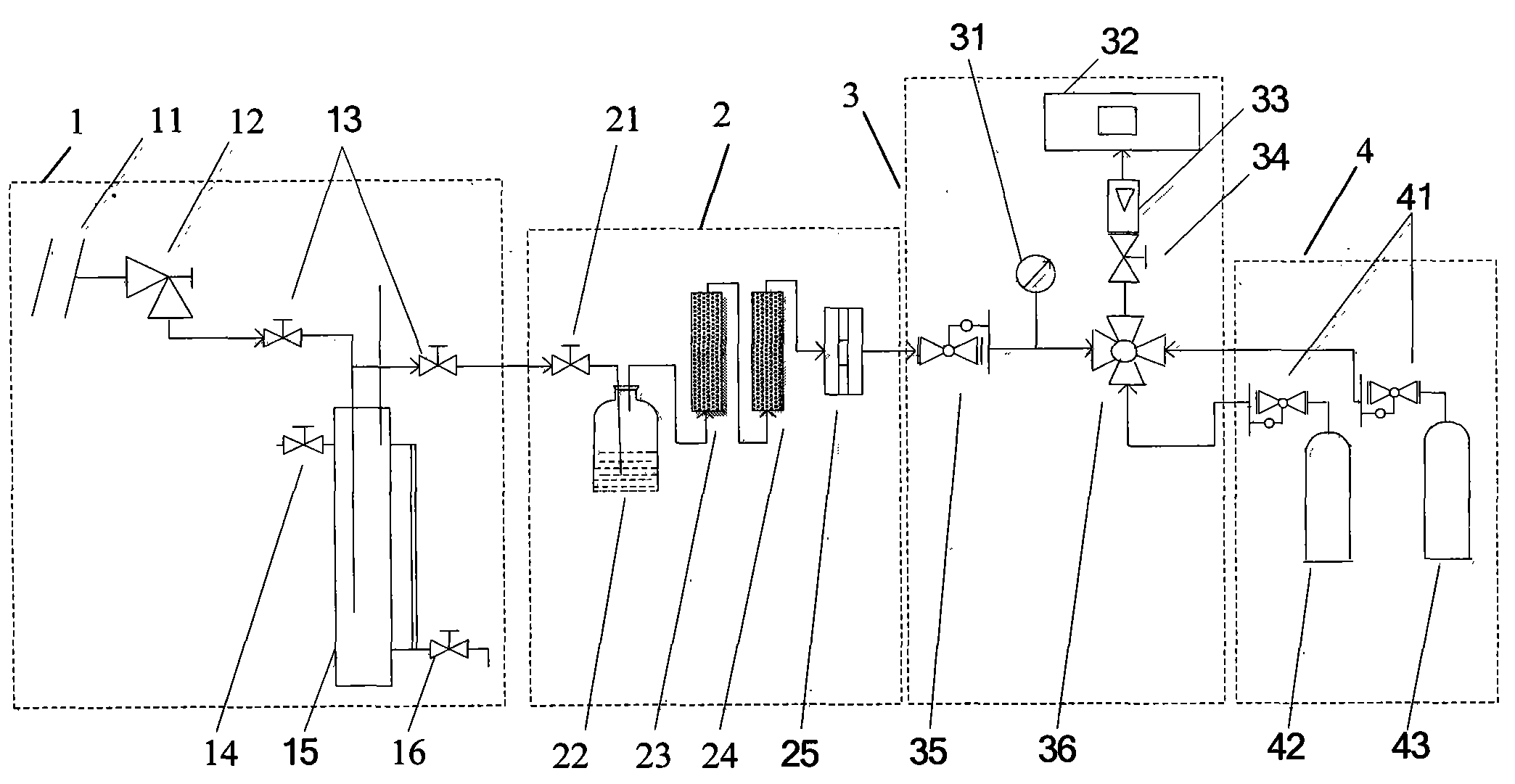

[0024] Such as figure 1 As shown, the online analysis system for detecting CO gas at the ammonia synthesis inlet of the present invention includes a sampling unit 1 , a pretreatment unit 2 , an analysis unit 3 and a calibration unit 4 connected in sequence.

[0025] The sampling unit 1 includes a double-flange high-pressure stop valve 12, a ball valve 13, a ball valve 14, a ball valve 16 and a water seal 15; the two ball valves 13 are installed in the air inlet and the air outlet of the water seal respectively, and the ball valve 14 and the ball valve 16 are the water injection ports of the water seal. valve and drain valve. In this embodiment, the double-flange high-pressure cut-off valve 12 adopts a model of J44H-320P.

[0026] The pretreatment unit 2 includes a water washing bottle 22 , a dryer 23 , a desulfurizer 24 and a filter 25 con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com