High-brightness dimmable COB light source, spot lamp COB process and fluorescent lamp COB process

A high-brightness, dimming technology, applied in the direction of electrical components, electrical solid-state devices, circuits, etc., can solve the problems of high production cost, unsuitable for large-area products, high cost of material base, etc., and achieve low production difficulty, simple structure, The effect of promoting the use of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

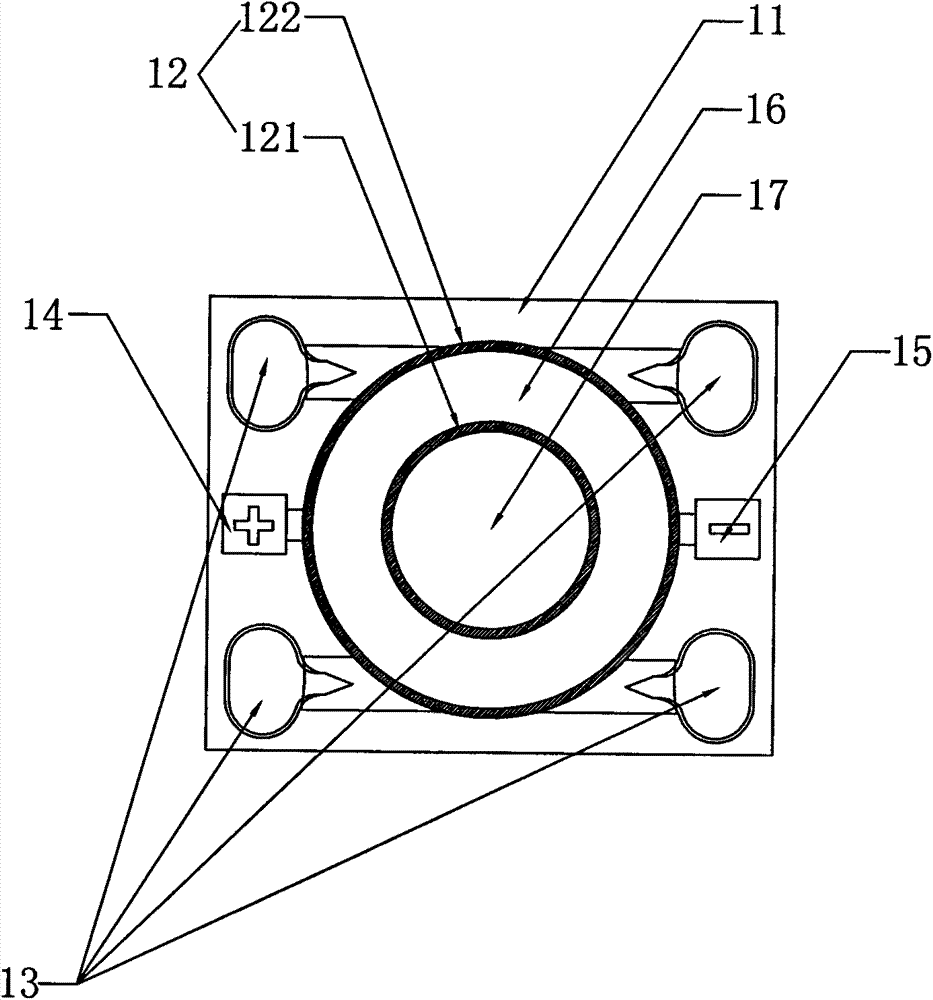

[0046] The first embodiment, in this embodiment, the barrier wall 12 divides the substrate 11 into a first light-emitting area 16 and a second light-emitting area 17; the first light-emitting area 16 is circular, the second light-emitting area 17 is circular, and the second The light emitting area 17 is located in the inner circle of the annular first light emitting area 16 ; the barrier wall 12 is located between the first light emitting area 16 and the second light emitting area 17 . The retaining wall 12 includes a first retaining wall 12 and a second retaining wall 122 ; the first retaining wall 12 is located between the first light-emitting area 16 and the second light-emitting area 17 , and the second retaining wall 122 is located on the periphery of the first light-emitting area 16 . The LED chips in the first light emitting area 16 are positive white LEDs, and the LED chips in the second light emitting area 17 are warm white LEDs.

[0047] The first embodiment is a hig...

no. 2 example

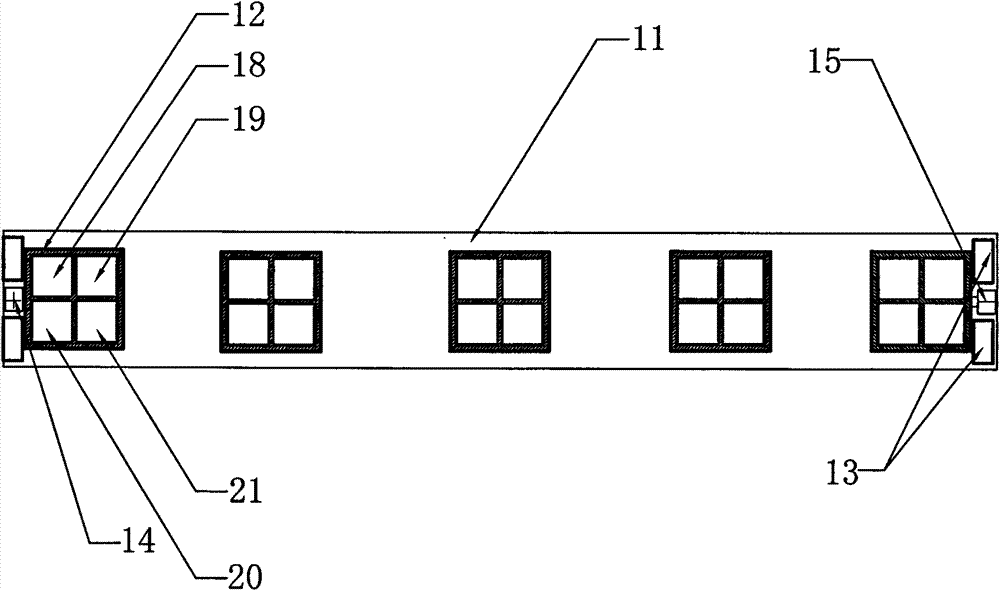

[0048]The second embodiment, in this embodiment, the barrier wall 12 divides the substrate 11 into the third light emitting area 18, the fourth light emitting area 19, the fifth light emitting area 20 and the sixth light emitting area 21; the third light emitting area 18, the sixth light emitting area The four light-emitting regions 19, the fifth light-emitting region 20 and the sixth light-emitting region 21 are joined together to form a rectangle; the colors of light emitted by the four light-emitting regions are not completely the same.

[0049] The second embodiment is a high-brightness two-color dimmable COB fluorescent lamp. The fluorescent lamp includes four light-emitting areas arranged in a square grid, and the four light-emitting areas are joined together to form a rectangle. Moreover, the colors of light emitted by the four light-emitting areas are not completely the same, and can be two-color or three-color. In the case of two colors, the LED chips in the third lum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com