High-uniformity side-lit LED plant illumination light source without light guide plate

A technology without light guide plate and plant lighting, which is applied in the direction of light source, electric light source, lighting device, etc. It can solve the problems of extensive structure, inability to meet the performance requirements of light source heat dissipation, uniformity, etc., and the decrease of light efficiency, so as to reduce light waste , good light mixing effect, avoid the effect of Fresnel diffraction phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

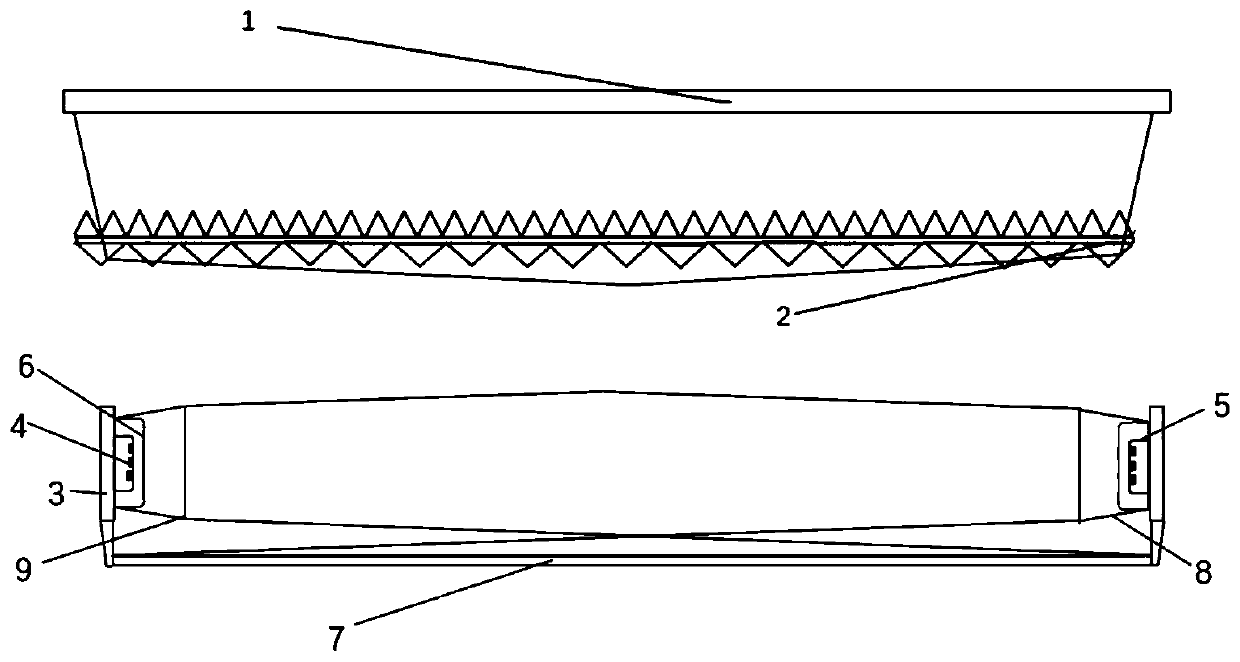

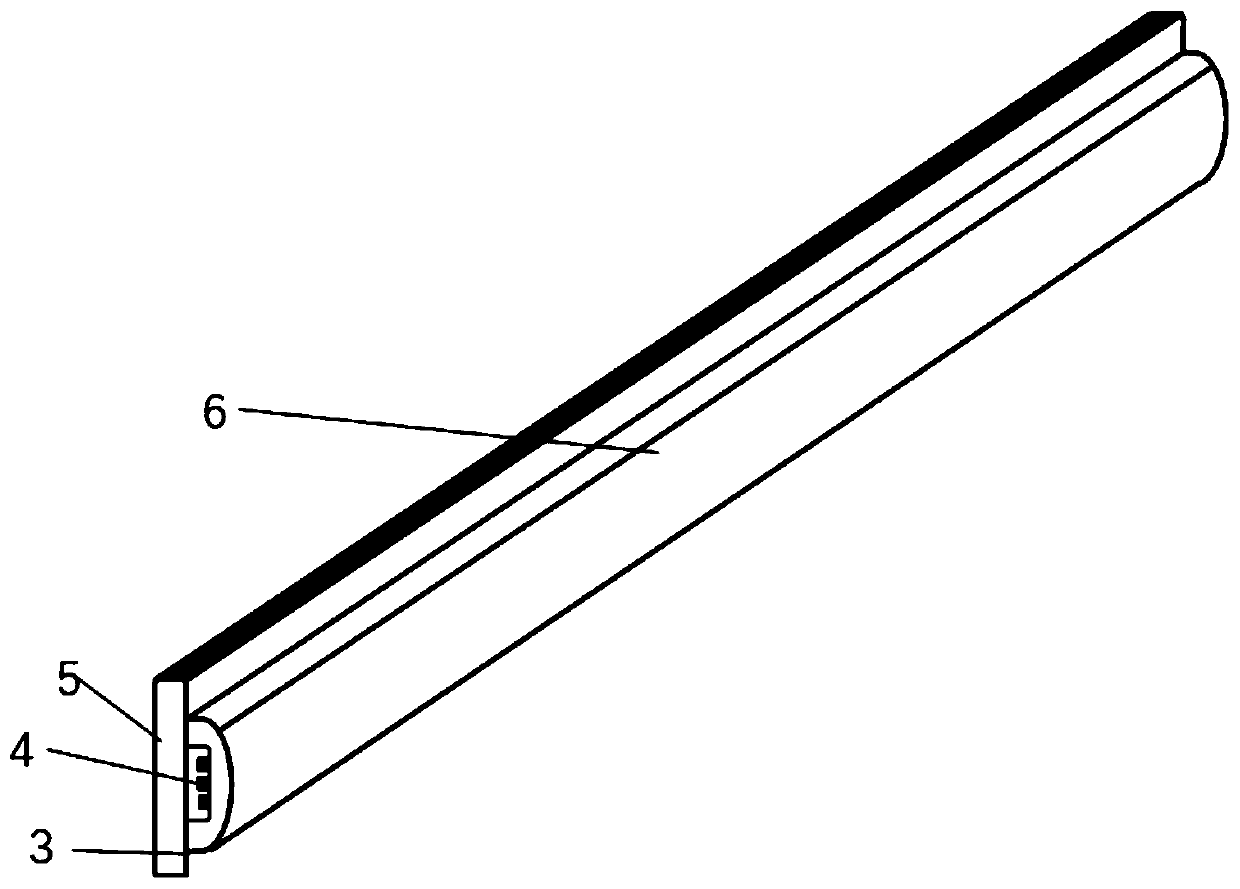

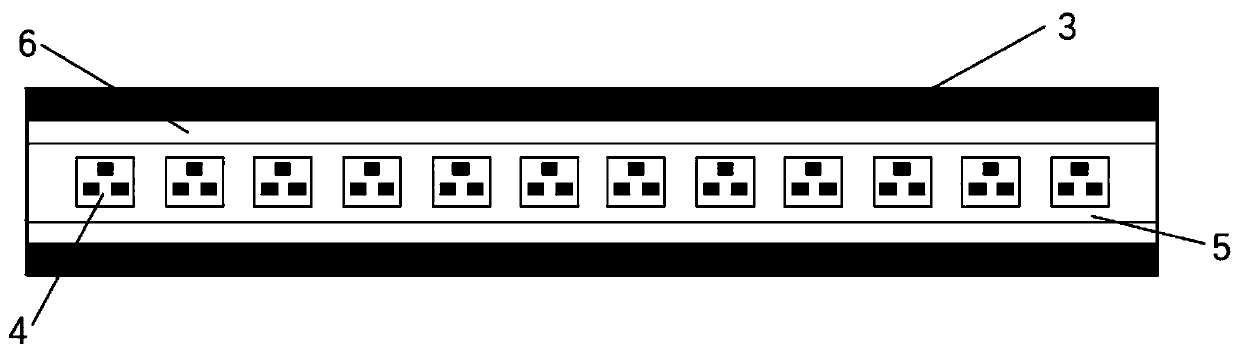

[0033] A high-uniformity side-entry LED plant lighting source without a light guide plate, such as figure 1 As shown, it includes brightness enhancement film 1, double-sided prism diffuser plate 2, surface light source frame 3, RGB three-color LED lamp beads 4, PCB circuit board 5, light mixing cover 6, reflective back plate 7, spotlight cup 8, condenser Light lens 9.

[0034] The surface light source frame 3 on both sides is installed on the rear reflective backboard 7, and the surface light source frame 3 and the reflective backboard 7 are combined at an angle of 90 degrees;

[0035] The double-sided prism diffuser 2 is placed in front of the surface light source frame 3, and the double-sided prism diffuser 2 is parallel to the reflective backplane 7;

[0036] The brightness enhancement film 1 is placed in front of the double-sided prism diffuser plate 2 , and the brightness enhancement film 1 is parallel to the reflective back plate 7 .

[0037] Such as Figure 2a with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com