Bent needle dispensing method

A needle and glue dispensing technology, which is applied to coatings, devices that apply liquid to the surface, etc., can solve the problems of difficulty and convenience, and it is difficult for a straight needle to complete the dispensing task, so as to achieve the effect of improving dispensing efficiency and rapid dispensing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

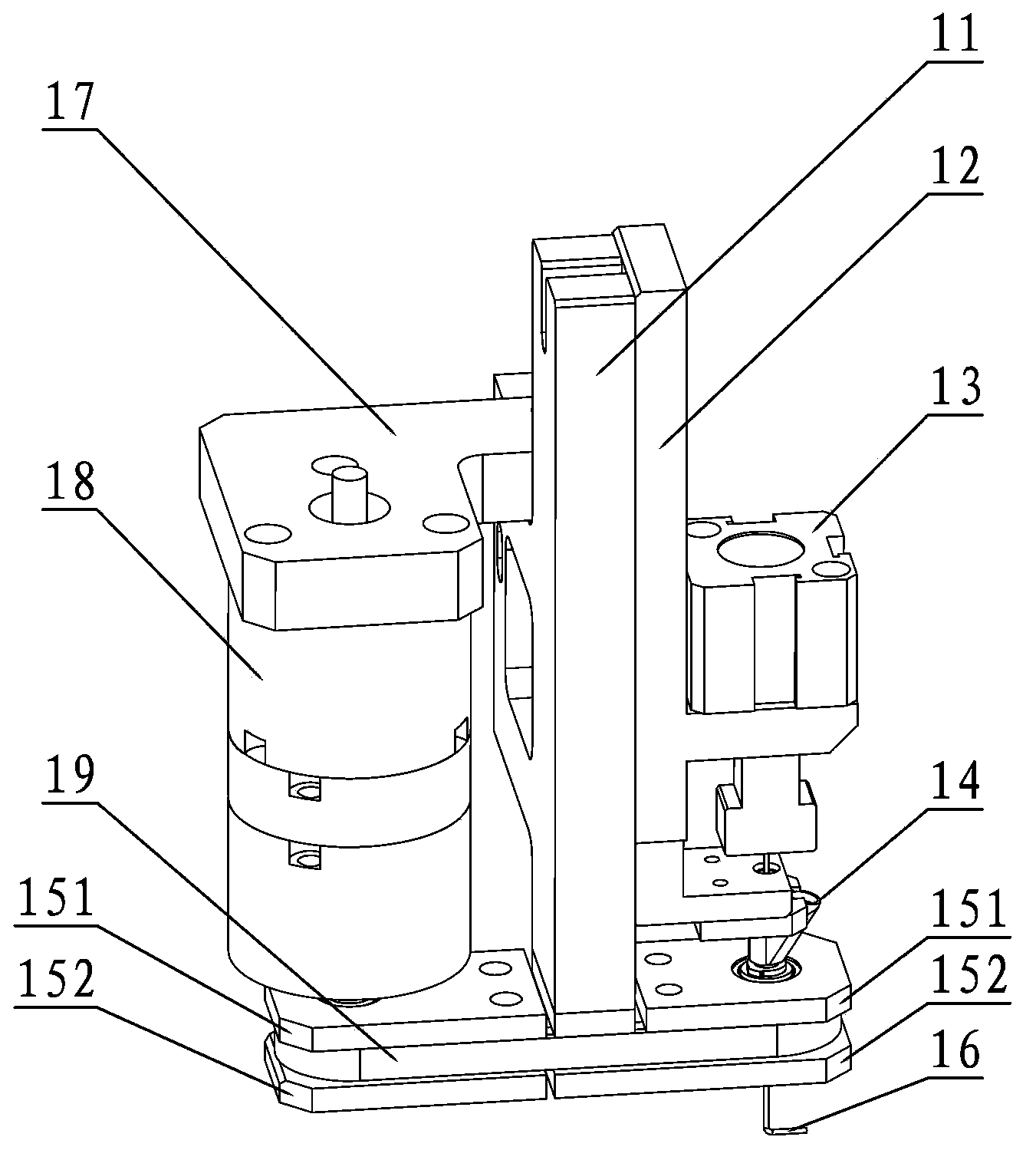

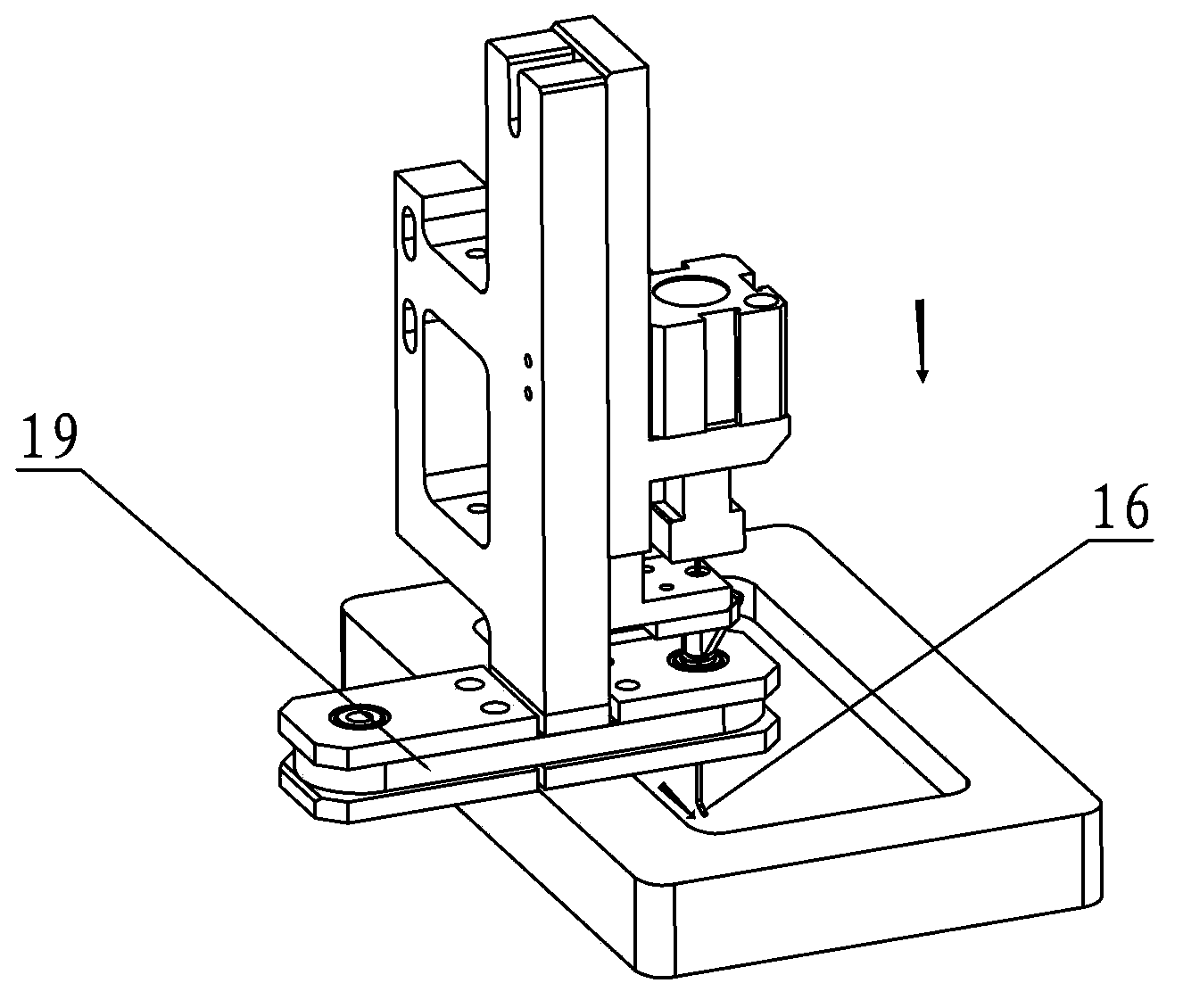

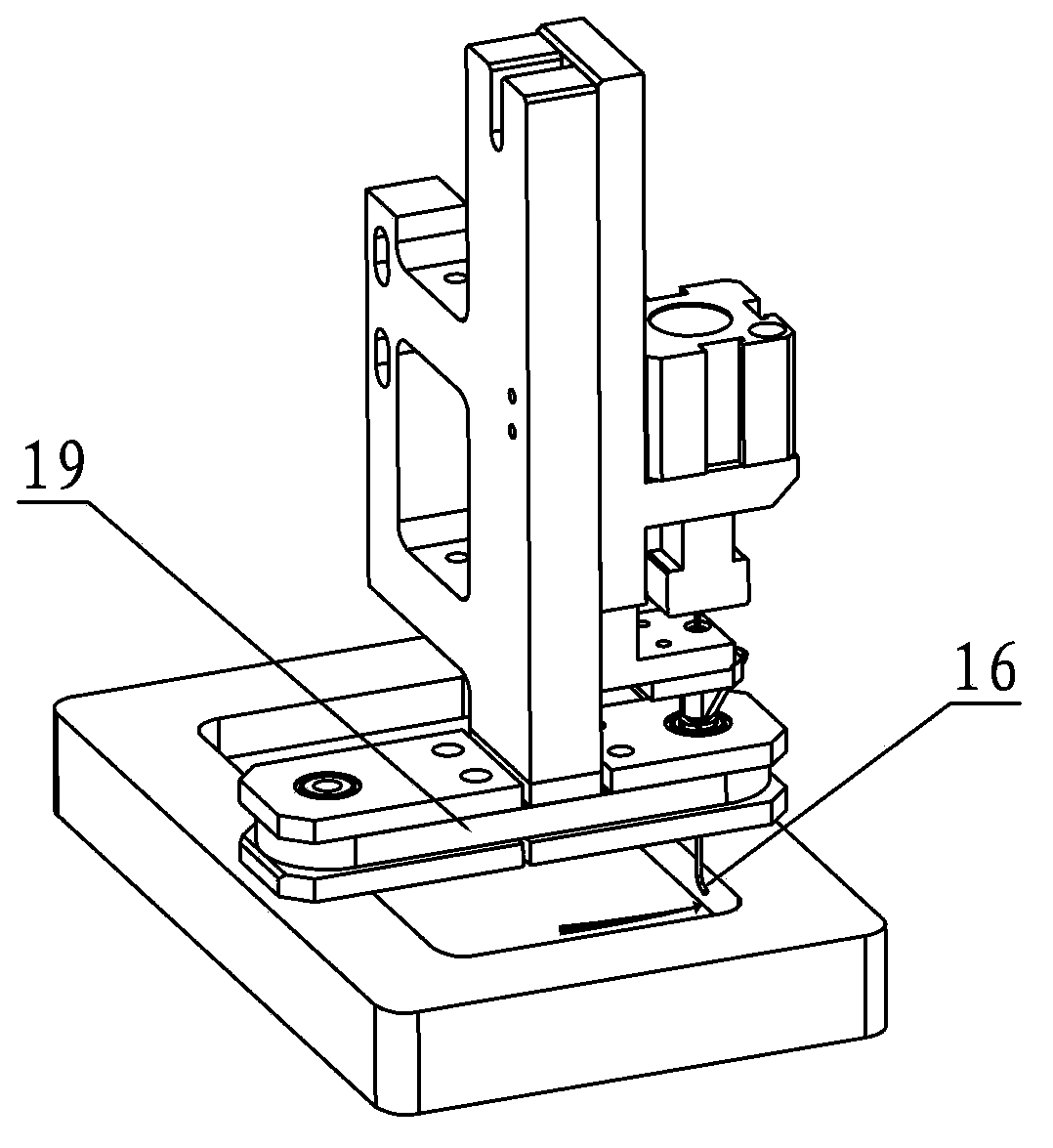

[0034] refer to figure 2 , first by moving the rotary positioning device to make the looper head 16 close to the side of the product that needs to be glued;

[0035] refer to image 3 , drive the rotary positioning device to move linearly to the first rounded corner, and make the looper head 16 correspond to the first rounded corner;

[0036] refer to Figure 4 , drive the looper head 16 to rotate 90° through the rotary positioning device, and dispense glue at the first rounded corner;

[0037] refer to Figure 5 After dispensing the first fillet, drive the rotary positioning device to move linearly to the second fillet, and make the looper head 16 correspond to the second fillet;

[0038] refer to Image 6 , drive the looper head 16 to rotate 90° through the rotary positioning device, and dispense glue at the second rounded corner;

[0039] refer to Figure 7 After dispensing the second rounded corner, drive the rotary positioning device to move straight to the third ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com