Biodegradation type snow melting deicing agent and preparation method thereof

A biodegradable and deicing agent technology, applied in the chemical field, can solve the problems of environmental hazards and incomplete degradation, and achieve the effect of strong snow melting and deicing ability and low corrosion

Active Publication Date: 2015-07-15

JIANGSU LOPALTECH

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the above-mentioned types of deicing agents cannot be completely degraded and have certain harm to the environment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

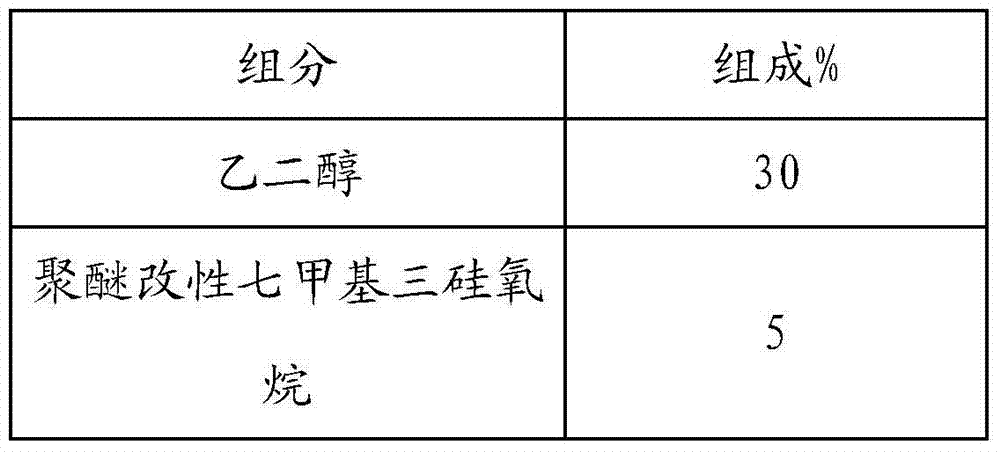

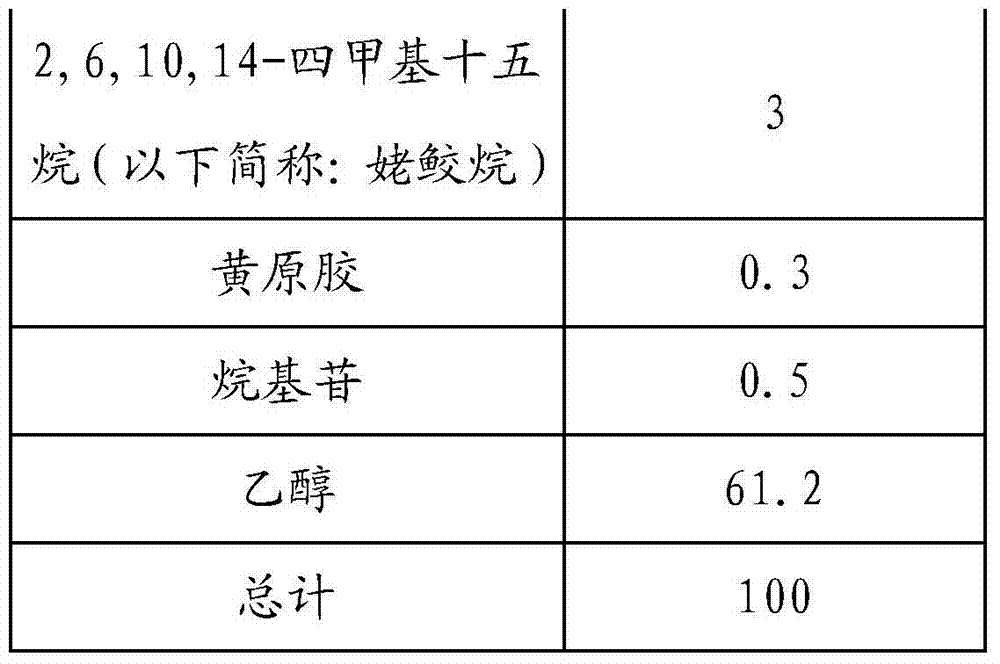

Embodiment 1

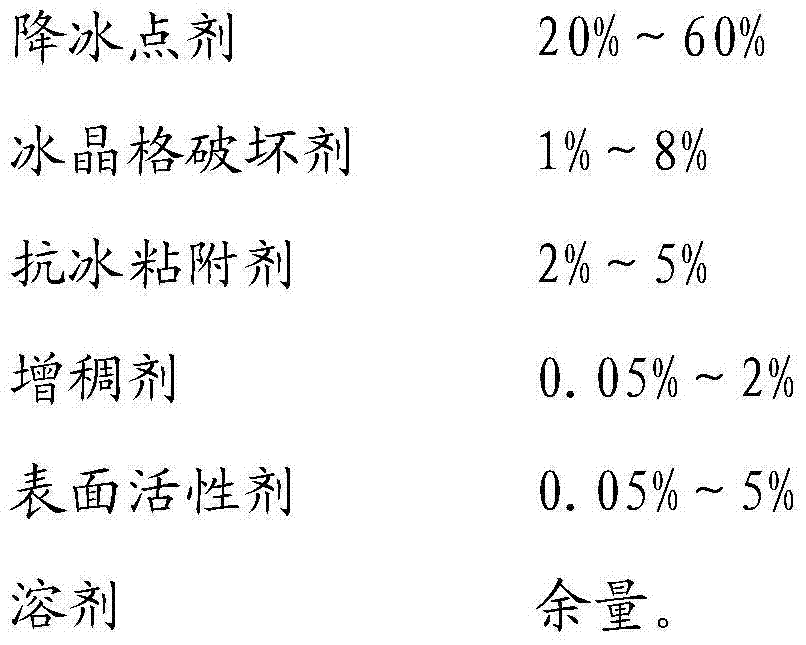

[0016] The component distribution ratio of this example is shown in Table 1 (by weight percentage):

[0017] Table 1

[0018]

[0019]

Embodiment 2

[0021] The component distribution ratio of this example is shown in Table 2 (by weight percentage):

[0022] Table 2

[0023]

Embodiment 3

[0025] The component distribution ratio of this example is shown in Table 3 (by weight percentage):

[0026] table 3

[0027]

[0028]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a snow melting deicing agent and a preparation method thereof, particularly relates to a biodegradation type snow melting deicing agent and a preparation method thereof, and belongs to the technical field of chemistry. The biodegradation type snow melting deicing agent comprises the following components in percentage by weight: 20%-60% of freezing point reducing agent, 1%-8% of ice lattice breaking agent, 2%-5% of anti-ice adhesive, 0.05%-2% of thickener, 0.05%-5% of surface active agent and the balance of solvent. The biodegradation type snow melting deicing agent has strong snow melting deicing capacity and extremely small corrosivity on metals and concrete. Importantly, the biodegradation type snow melting deicing agent is easy to biologically degrade and almost harmless to human bodies, animals, plants and microorganisms and is a full biodegradation type snow melting agent which can be used for rapidly melting ice and snow.

Description

technical field [0001] The invention relates to a snow-melting and ice-melting agent and a preparation method thereof, in particular to a biodegradable snow-melting and ice-melting agent and a preparation method thereof, belonging to the field of chemical technology. Background technique [0002] In the alpine regions of our country and many countries in the world, ice and snow in winter have become a serious public nuisance. The deep snow and smooth road surface have caused serious consequences such as traffic jams, accidents, highway outages, and airport closures. Generally, the snow-melting and deicing agent is sprayed on the surface after snow to achieve the snow-melting and deicing effect. The development of snow-melting and deicing agents has gone through a single salt type, an inorganic chlorine salt type, an organic type, and a compound anti-corrosion type. However, the above-mentioned types of deicing agents cannot be completely degraded and have certain harm to th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09K3/18

Inventor 石俊峰严军表

Owner JIANGSU LOPALTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com