A liquid anti-ice and snow material and its combined use method with a solid ice and snow melting material

An ice-snow and liquid technology, applied in the development of liquid anti-icing and snowing materials, can solve the problems of loss of anti-icing and snowing materials, long efficacy time, increased environmental burden, etc. , The effect of promoting the ability to melt snow and ice

Active Publication Date: 2020-10-02

CHINASALT JINTAN

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Each of the above three methods has advantages and disadvantages. (1) At present, the anti-ice and snow materials generally adopt solid salts or salt aqueous solutions, which are easy to use. At the same time, it will be quickly diluted by the melting ice and snow. In the case of heavy use, when the road surface temperature is higher than the freezing point of the solution, it will cause the rapid loss of anti-ice and snow materials. When the road surface temperature is lower than the freezing point of the solution, the diluted solution It is easy to freeze into ice again, causing greater road traffic hazards

(2) Due to the low efficiency of mechanical snow removal and the difficulty of operation after the road surface is frozen, it is more necessary to use it together with snow melting materials to effectively reduce or eliminate the bonding force between the ice layer and the road surface

(3) Using solid snow melting agent alone, firstly, the spherical snow melting agent particles are easy to slide to the road shoulder during the throwing process, resulting in uneven spreading and waste of snow melting agent, as well as increasing the burden on the environment

Secondly, the solid deicing agent needs to absorb moisture from the environment and dissolve before it can play its role in melting snow and ice, and it takes a long time to play its role

At the same time, since the solid deicing agent is spread after snow falls or freezes, it will take longer to penetrate the thicker ice layer and melt the ice layer combined with the road surface.

[0004] In addition, the main damage to the environment caused by the use of traditional antifreeze and deicing products is its corrosion on metal, concrete and asphalt pavement, so what kind of corrosion inhibitor to add to reduce the corrosion of deicing agents has become an efficient development all over the world. The main goal of environmental protection products, related research work has been carried out in China, but there are still problems such as unsatisfactory corrosion inhibition effect, high cost, and small addition amount makes it difficult to mix the product evenly.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

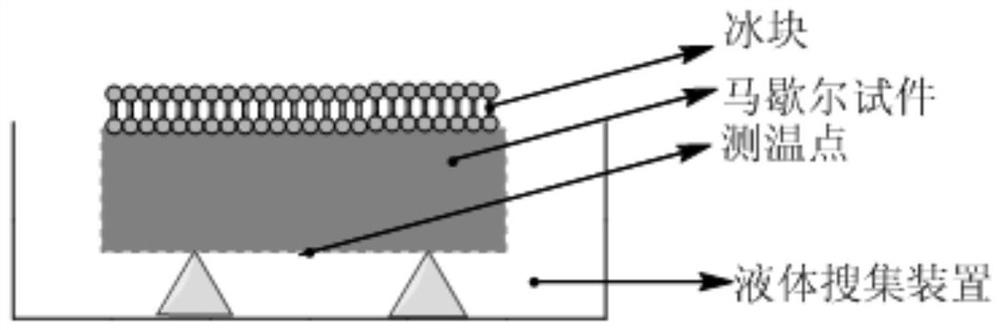

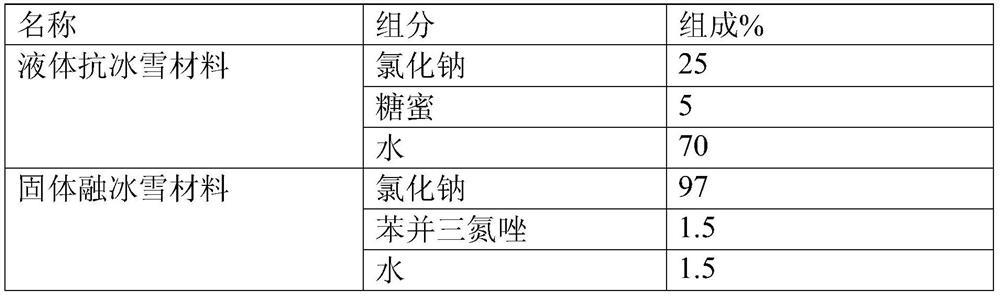

[0028] The component distribution ratio of the present embodiment is shown in Table 1 (by mass percentage)

[0029]

Embodiment 2

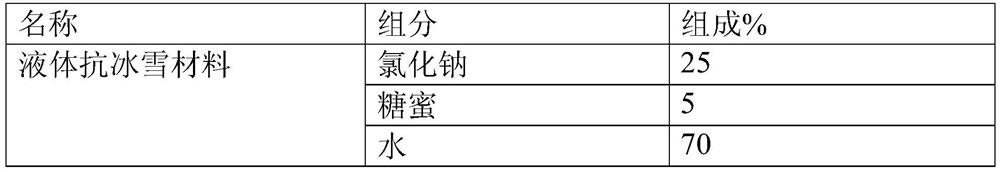

[0031] The component distribution ratio of the present embodiment is shown in Table 2 (by mass percentage)

[0032]

Embodiment 3

[0034] The component distribution ratio of the present embodiment is shown in Table 3 (by mass percentage)

[0035]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides a liquid anti-ice-snow material and a 'first liquid and later solid' combined use method of a liquid anti-ice-snow material and a solid ice-snow-melting material. According to the use method, before snowfall comes or just starts, the liquid anti-ice-snow material is spread to the pavement, and the material has the advantages that when sprayed, the material does not easily slide to the road shoulder, does not quickly run off since an ice and snow solution is diluted, can generate an isolation layer on the pavement to prevent ice and snow from being bonded on the pavement, and cannot cause erosion to the pavement. When the phenomenon that snow is accumulated or frozen occurs, the solid ice-snow-melting material is spread. The two materials are used in combination, the dose of the liquid anti-ice-snow-melting material is one tenth that of the solid ice-snow-melting material, enough humidity can be directly provided for the solid ice-snow-melting material, and a synergistic effect can be generated to achieve a better effect of melting ice and snow. The liquid-ice-snow material is prepared from, by mass, 20%-65% of a freezing point inhibitor, 1%-10% of carbohydrate and 27%-79% of water.

Description

technical field [0001] The invention relates to a combined use method of snow-melting materials, in particular to the development of a liquid anti-ice and snow material and its combined use with solid ice-melting and snow-melting materials. Background technique [0002] The snow and ice on the road surface in winter seriously affects people's travel safety. Usually there are three snow removal methods: (1) anti-ice and snow operations, which prevent snow and ice from freezing on the road surface by chemical methods; (2) mechanical snow removal operations, which use Large-scale mechanical equipment removes accumulated snow from the road surface; (3) ice and snow melting operation, promptly removes accumulated snow accumulated on the road surface by chemical methods. [0003] Each of the above three methods has advantages and disadvantages. (1) At present, the anti-ice and snow materials generally adopt solid salts or salt aqueous solutions, which are easy to use. At the same...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09K3/18

CPCC09K3/185

Inventor 陈留平徐俊辉韩俊甜苏志俊崔耀星

Owner CHINASALT JINTAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com