Biomass environment-friendly non-chlorine deicing and snow-melting agent and preparation method thereof

An environmentally friendly, biomass technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of excessive chemical oxygen consumption, large oxygen consumption, etc., to achieve low biochemical and chemical oxygen consumption, weak corrosion, The effect of wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

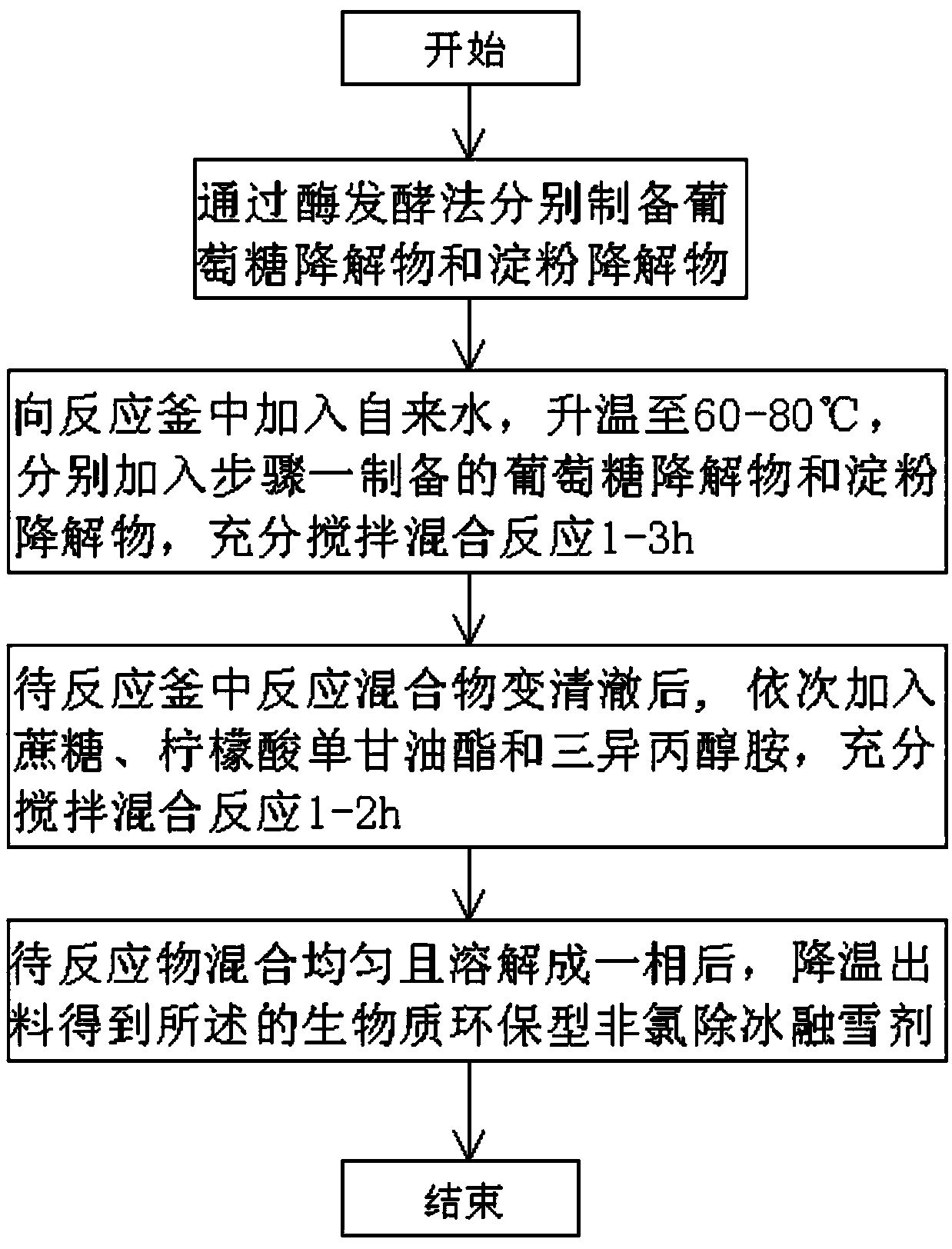

[0025] See attached figure 1 - attached figure 2 As shown, a kind of biomass environment-friendly non-chlorine deicing deicing agent of the present invention is made up of the raw material of following mole fraction: 10 parts of tap water, 15 parts of glucose degradation product, 6 parts of starch degradation product, 8 parts of microcrystalline sucrose, 7 parts of monoglyceride citrate and 2 parts of triisopropanolamine.

[0026] See attached figure 1 Shown, the preparation method of a kind of biomass environment-friendly non-chlorine deicing deicing agent of the present invention, comprises the steps:

[0027] Step 1: First, glucose degradants and starch degradants are prepared respectively by enzyme fermentation;

[0028] Step 2: Then, add tap water to the reaction kettle, raise the temperature to 60°C, add the glucose degradation product and starch degradation product prepared in Step 1 respectively, and fully stir and mix for 1 hour;

[0029] Step 3: Next, after the ...

Embodiment 2

[0033] See attached figure 1 - attached figure 2 As shown, a kind of biomass environment-friendly non-chlorine deicing deicing agent of the present invention is made up of the raw material of following mole fraction: 15 parts of tap water, 20 parts of glucose degradation product, 12 parts of starch degradation product, 12 parts microcrystalline sucrose, 10 parts of monoglyceride citrate and 3 parts of triisopropanolamine.

[0034] See attached figure 1 Shown, the preparation method of a kind of biomass environment-friendly non-chlorine deicing deicing agent of the present invention, comprises the steps:

[0035] Step 1: First, glucose degradants and starch degradants are prepared respectively by enzyme fermentation;

[0036] Step 2: Then, add tap water to the reactor, raise the temperature to 65°C, add the glucose degraded product and starch degraded product prepared in Step 1, and fully stir and mix for 1.5 hours;

[0037] Step 3: Next, after the reaction mixture in the ...

Embodiment 3

[0041] See attached figure 1 - attached figure 2 As shown, a kind of biomass environment-friendly non-chlorine deicing deicing agent of the present invention is made up of the raw material of following mole fraction: 20 parts of tap water, 25 parts of glucose degradation products, 15 parts of starch degradation products, 14 parts microcrystalline sucrose, 12 parts of monoglyceride citrate and 4 parts of triisopropanolamine.

[0042] See attached figure 1 Shown, the preparation method of a kind of biomass environment-friendly non-chlorine deicing deicing agent of the present invention, comprises the steps:

[0043] Step 1: First, glucose degradants and starch degradants are prepared respectively by enzyme fermentation;

[0044] Step 2: Then, add tap water to the reaction kettle, raise the temperature to 70°C, add the glucose degradation product and starch degradation product prepared in Step 1, and stir and mix for 2 hours;

[0045] Step 3: Next, after the reaction mixture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com