A continuous ice breaking mechanism

A technology of ice breakers and connecting rods, which is applied in water conservancy projects, cleaning of open water surfaces, construction, etc., can solve the problems of slow ice breaking speed, achieve the effect of improving ice breaking efficiency and reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

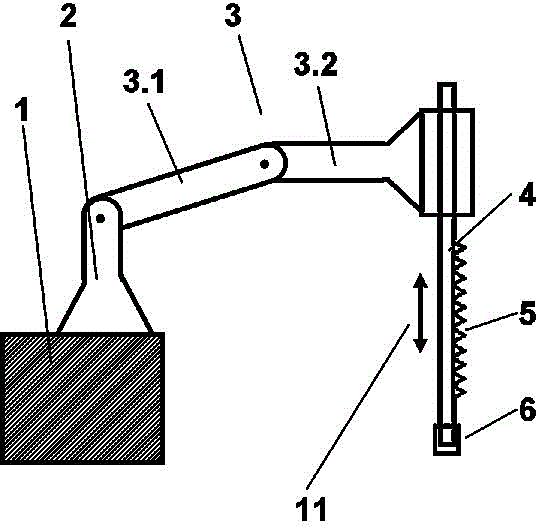

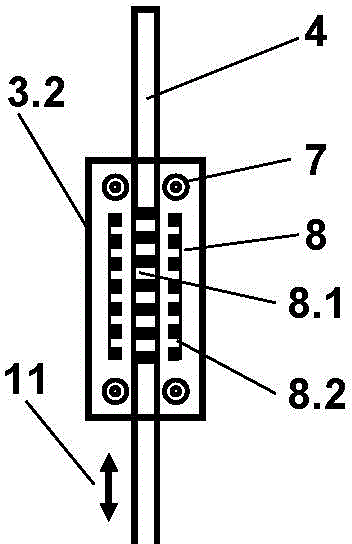

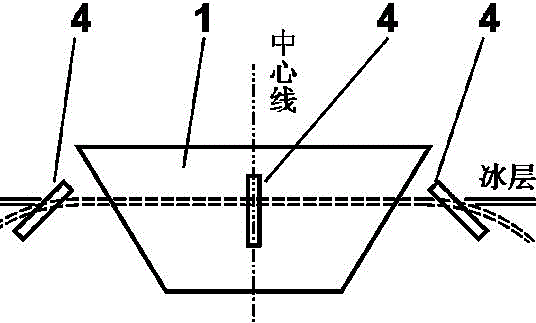

[0015] The following is attached with the manual figure 1 , 2 , 3, 4 further describe the present invention.

[0016] An icebreaker 1 constructed using the present invention operates in the ice region, and its continuous icebreaking mechanism is as follows: figure 1 , the continuous ice breaking mechanism includes a bracket 2, a mechanical arm 3, a linear motor 8, a toothed rod 4, and a rotating ice breaker 6. Wherein, bracket 2 connects and supports mechanical arm 3; Mechanical arm 3 connects the upper end of toothed rod 4, supports toothed rod 4, is also used for adjusting the angle of toothed rod 4, and toothed rod 4 can be clamped by mechanical arm 3 under the condition of reciprocating up and down 11; the linear motor 8 is located at the junction of the mechanical arm 3 and the toothed rod 4, and is used to drive the toothed rod 4 to make up and down reciprocating motion 11; the front side of the toothed rod 4 is equipped with sawtooth 5 for Cut the ice layer; the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com