Surge pressure control short joint

A pressure-activating and sub-joint technology, applied in the direction of drill pipe, casing, drill pipe, etc., can solve problems such as increased operating time and cost, drill sticking, formation fracture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

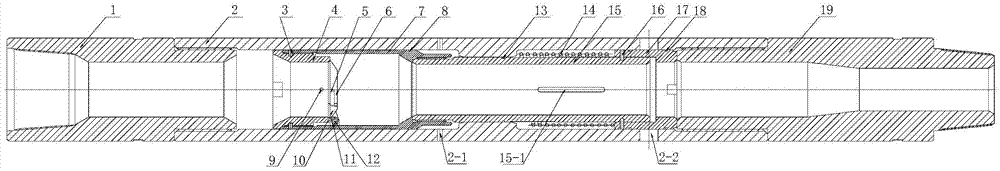

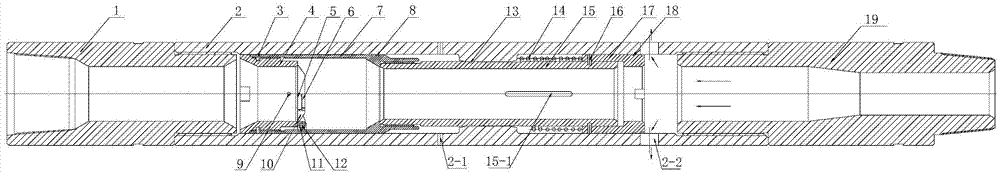

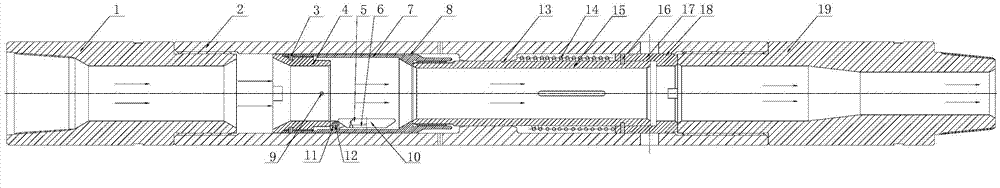

[0027] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0028] see figure 1 , the activation pressure control pup joint, including the tool connection mechanism, the middle pup joint 2 and the internal pressure relief mechanism, the tool connection mechanism includes the upper joint 1 connected with the upper tool and the lower joint 19 connected with the lower tool, the middle short The joints are respectively connected with the upper joint and the lower joint of the tool connection mechanism, and the upper part of the lower joint is formed with a limit step that can realize the downward limit of the internal pressure relief mechanism. An internal pressure relief mechanism is installed in the middle nipple, and the internal pressure relief mechanism includes a valve seat 4, a valve seat sleeve 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com