Multi-layer welding device

A welding device and multi-layer welding technology, applied in welding equipment, arc welding equipment, program control manipulator, etc., can solve the problems of time-consuming and excessive time, and achieve the effect of shortening the confirmation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 2

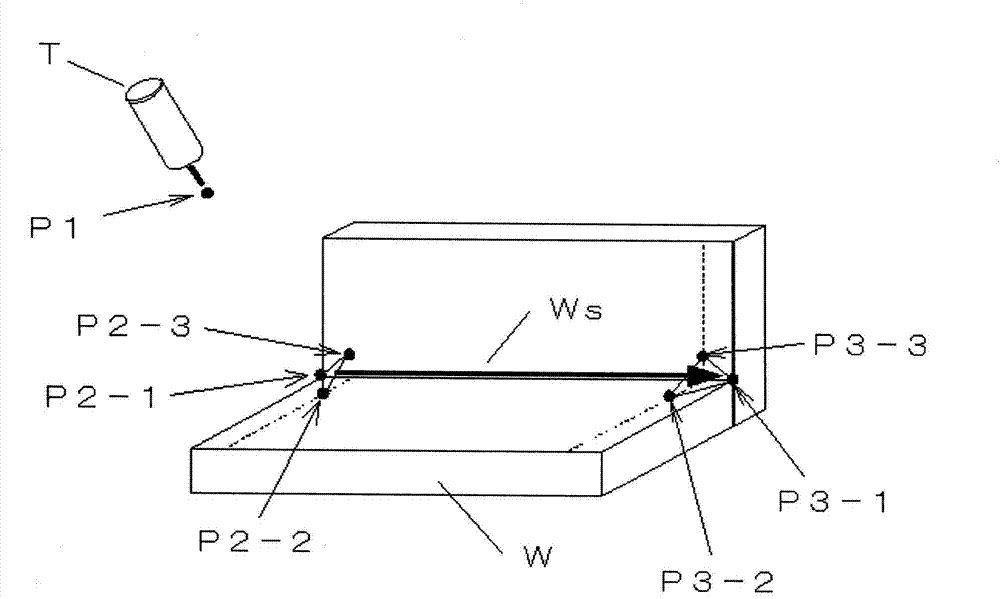

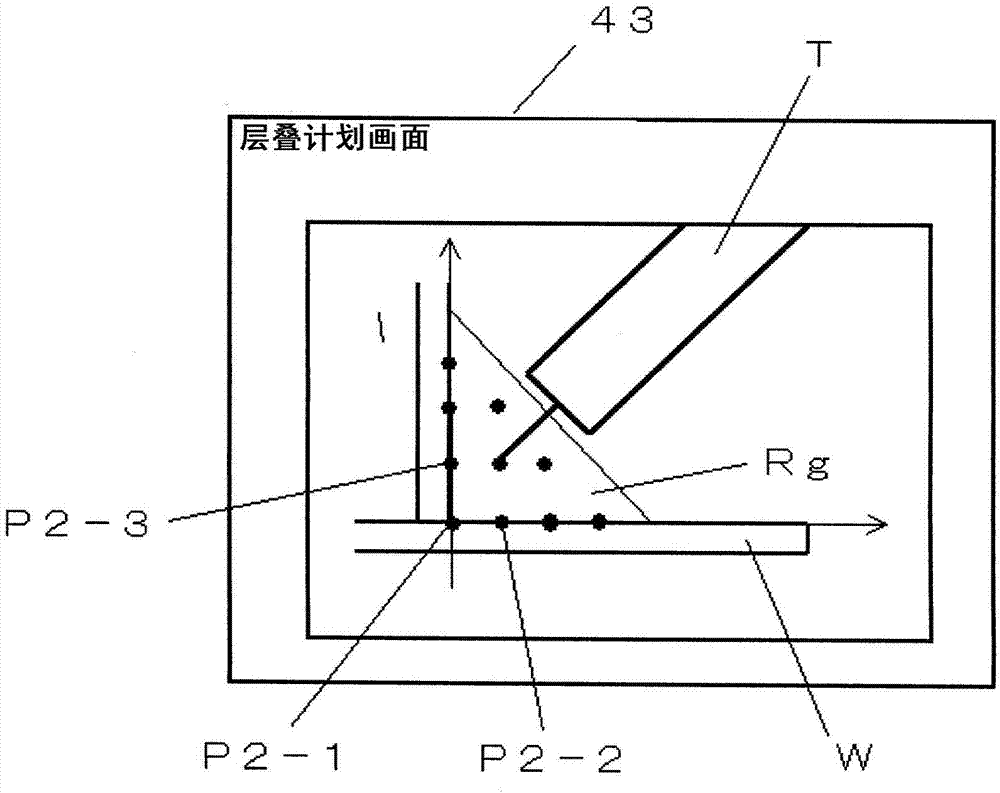

[0099]Next, a second embodiment of the invention will be described. In the second embodiment, the welding start point or the welding end point on each welding pass is represented as point information on a plane perpendicular to the welding proceeding direction, and displayed on the display unit 43 of the teach pendant TP (refer to Figure 5 )superior. And, the welding pass of the transfer destination can be selected using this display. Hereinafter, details will be described.

[0100] image 3 It is a diagram showing the welding start point on each welding pass by point information on a plane perpendicular to the welding progress direction. This illustration shows what is displayed on the display unit 43 of the teach pendant TP. As shown in the figure, the workpiece W and the welding torch T are imaginary displayed, and the welding start points on each welding pass (including figure 2 All welding start points of P2-1, P2-2, and P2-3 exemplified in ). The curve position o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com