Continuous drying squeezing device for loose fibers

A loose fiber, continuous technology, applied in the field of water rolling devices, can solve the problems of high manufacturing cost, low dewatering efficiency, high labor intensity, and achieve the effects of high water rolling speed, good dewatering uniformity, and avoiding insufficient opening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

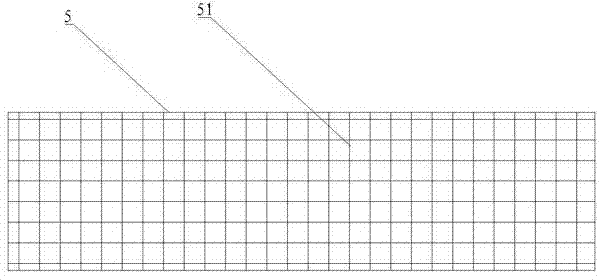

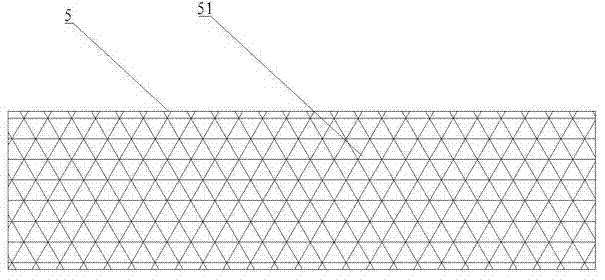

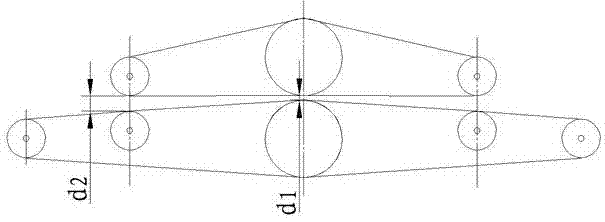

[0027] In this embodiment, the water rolling device for continuous drying of loose fiber or loose fiber cake, combined with figure 1 , comprising an upper conveyor belt 10, a lower conveyor belt 5, an upper pressure roller 6, a lower pressure roller 7, a pair of upper driving rollers 8 and a pair of lower driving rollers 4a, the upper conveyor belt 10 and the lower conveyor belt 5 are high-strength rubber belt, combine figure 2 , the lower conveyor belt 5 is provided with a water filter hole 51, the diameter of the water filter hole 51 is 1mm, and the opening rate is 80%. Between 4a, the upper pressure roller 6 and the lower pressure roller 7 are respectively installed in the loop of the upper conveyor belt 10 and the lower conveyor belt 5, and there is a gap for loose fibers to pass between the lower pressure roller 7 and the upper pressure roller 6. The height of the gap is the distance d between the upper conveyor belt and the lower conveyor belt 1 The upper conveyor bel...

Embodiment 2

[0031] In this embodiment, the water rolling device for continuous drying of loose fiber or loose fiber cake, combined with figure 1 , comprising an upper conveyor belt 10, a lower conveyor belt 5, an upper pressure roller 6, a lower pressure roller 7, a pair of upper driving rollers 8 and a pair of lower driving rollers 4a, combined figure 2, the lower conveyor belt 5 is provided with a water filter hole 51, the aperture of the water filter hole 51 is 2mm, and the opening rate is 70%. An auxiliary drive roller 4b corresponding to the upper drive roller 8 is arranged between a pair of lower drive rollers 4a, When the amount of fiber on the lower conveyor belt 5 is large, in order to avoid the falling of the lower conveyor belt 5 and affect the clamping of loose fibers between the upper conveyor belt 10 and the lower conveyor belt 5, an auxiliary driving roller is set at the corresponding position below the upper driving roller 8 4b, ensure that the distance between the upper ...

Embodiment 3

[0035] In this embodiment, the water rolling device for continuous drying of loose fiber or loose fiber cake, combined with figure 1 , including an upper conveyor belt 10, a lower conveyor belt 5, an upper pressing roller 6, a lower pressing roller 7, a pair of upper driving rollers 8 and a pair of lower driving rollers 4a. in:

[0036] The feeding device 3 is arranged in front of the lower conveyor belt 5, and the feeding device 3 includes a feeding belt 1 → a cake opening beater 1 31 → a feeding belt 2 2 → a cotton stripping beater 1 32, a nail conveying curtain 1 33, and a cotton opening beater 1 34 → conveyor belt 38→Cotton stripping beater 2 35, nail conveying curtain 2 36, cotton opening beater 2 37, wherein stripping beater-nail conveying curtain-cotton opening beater constitute a group of fine opening, each feeding device contains two or More than two fine openings, each group of fine openings is conveyed through the conveyor belt 38 in transition.

[0037] An auxili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com