A continuous water rolling and drying process for bulk fiber or bulk fiber cake

A loose fiber and water rolling technology, which is applied in the field of continuous water rolling and drying process of loose fiber or loose fiber cake, can solve the problems of high manufacturing cost, low dehydration efficiency, high labor intensity, etc., achieve good dehydration uniformity, avoid cracking Insufficient loosening and fast water rolling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

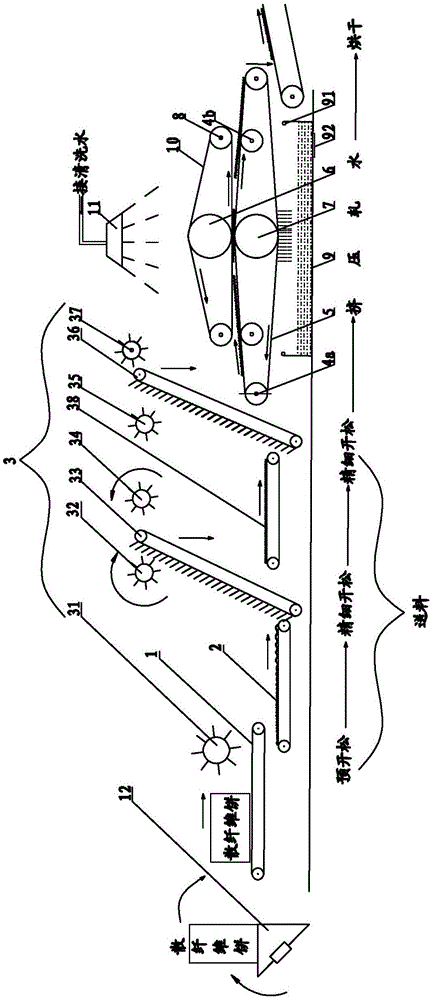

[0026] In this embodiment, the bulk fiber or bulk fiber cake continuous water rolling and drying process, combined with figure 1 , including three steps of feeding, squeezing water and drying,

[0027] (1) Feeding: Put the loose fibers of chemical fiber polyester to be treated evenly on the feeding belt (feeding belt 1), and send it to the water rolling device in the water rolling process from the feeding belt 1.

[0028] (2) Squeeze and squeeze water: the bulk fiber is sent to the water squeeze device, and the extrusion strength and conveying speed are controlled to squeeze out the water in the loose fiber.

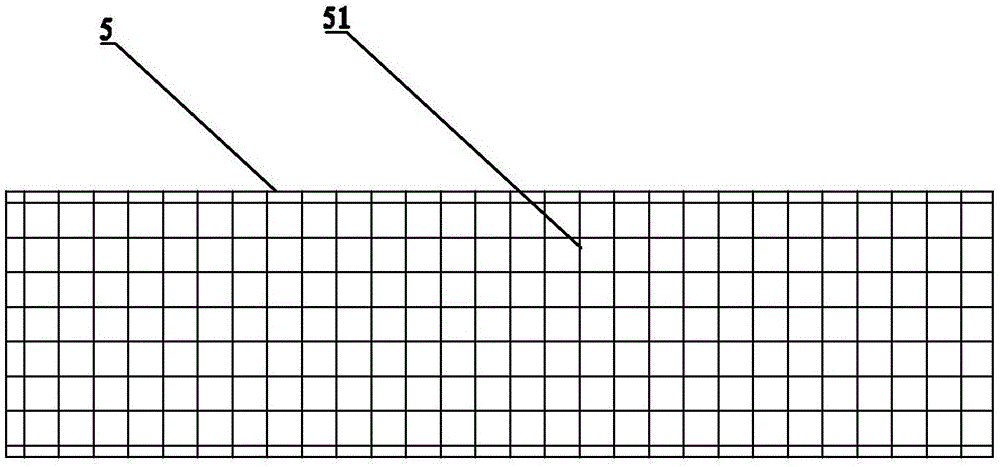

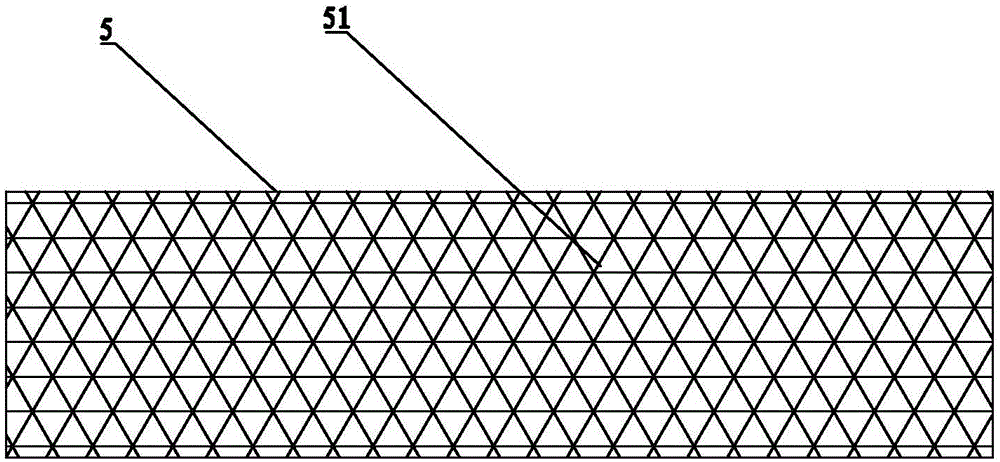

[0029] Wherein, water milling device comprises and comprises upper conveyer belt 10, lower conveyer belt 5, upper pressure roller 6, lower pressure roller 7 and a pair of upper drive roller 8 and a pair of lower drive roller 4a, upper conveyer belt 10 and lower conveyer belt 5 Both are high-strength rubber belts, combined with figure 2 , the lower conveyor belt 5 is p...

Embodiment 2

[0035] In this embodiment, the bulk fiber or bulk fiber cake continuous water rolling and drying process, combined with figure 1 , including feeding, opening, rolling and drying,

[0036] (1) Feeding: Place the loose fiber cake of natural plant cotton to be processed on the feeding belt 1, and send it to the extrusion and water rolling process.

[0037] Among them, at least two openings are carried out during the feeding process, and the loose fiber cake is opened step by step. The loose fiber is opened into small cakes; after fine opening, the loose fiber in the state of small cakes is opened into a flat and uniform loose fiber blanket.

[0038] In the above-mentioned feeding process, the pre-opening is realized by the cake opening beater 31, which is located above the feeding belt and is used for cake opening; the fine opening is realized by the cotton stripping beater, the nailed conveying curtain and the cotton opening beater , the cotton stripping beater and the cotton ...

Embodiment 3

[0045] The setting and working principle of this embodiment are the same as that of Embodiment 2, the difference is:

[0046] In step (1), the feeding process includes one pre-opening and two fine openings, and the fiber is conveyed through the conveyor belt 38 between the two fine openings, and the loose fibers pass through the feeding belt-1→cake beater-31→ Feeding belt two 2→ cotton stripping beater one 32, nail conveying curtain one 33, cotton opening beater one 34→ conveyor belt 38→ cotton stripping beater two 35, nail conveying curtain two 36, cotton opening beater two 37.

[0047] In step (2), the water rolling device used for extrusion rolling includes an upper conveyor belt 10, a lower conveyor belt 5, an upper pressure roller 6, a lower pressure roller 7, a pair of upper driving rollers 8 and a pair of lower driving rollers 4a, An auxiliary driving roller 4b corresponding to the upper driving roller 8 is arranged between a pair of lower driving rollers 4a. If the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com