Branched flow channel type self-adaptation inflow control device

An inflow control and self-adaptive technology, applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problems of EquiFlowAICD's complex structure and poor applicability, so as to ensure long-term stable production, suppress flow, and increase flow Effect of resistance level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

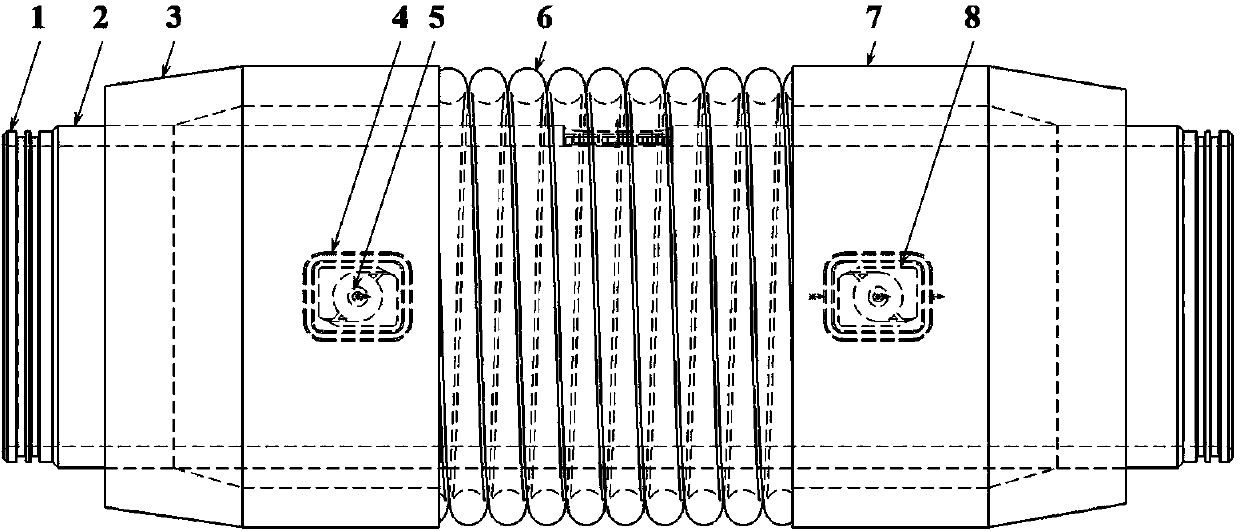

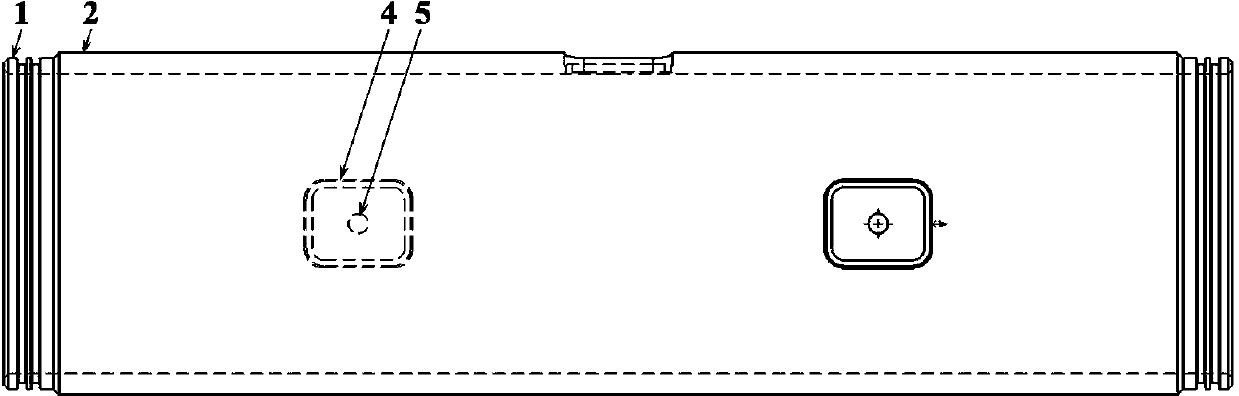

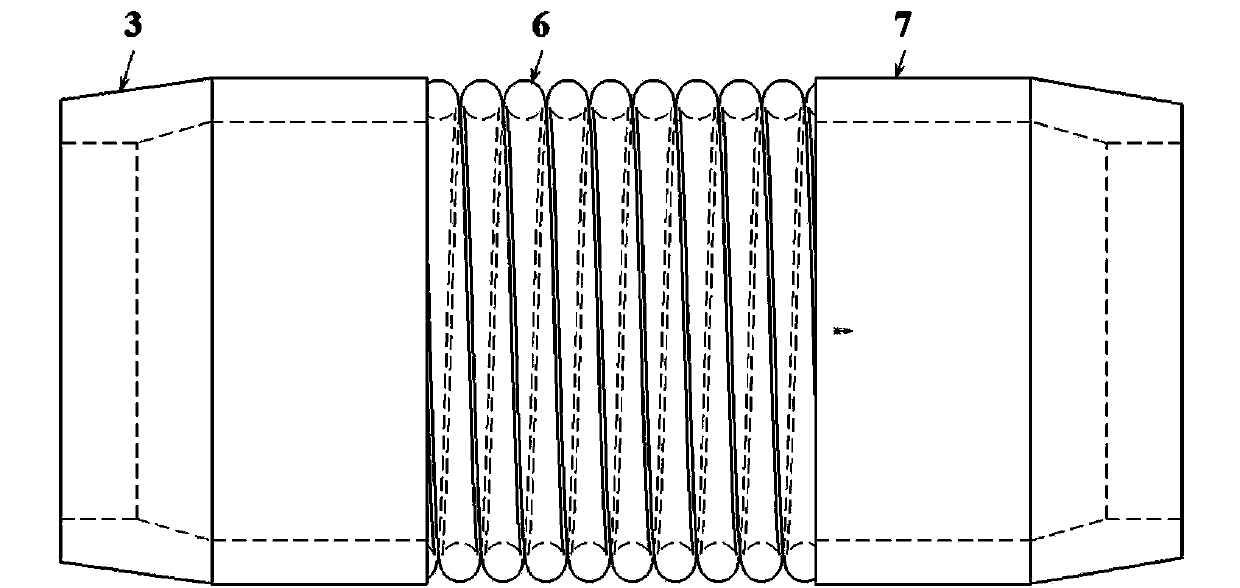

[0014] Below in conjunction with accompanying drawing, content of the invention will be further described: with reference to Figure 1-Figure 4 As shown, the bifurcated channel type adaptive inflow control device includes a base pipe 2, an upper outer casing 3, a sand control screen 6, a lower outer casing 7 and a bifurcated inflow control box 8, which is characterized in that: the two ends of the base pipe 2 are connected to The connected oil pipes are connected through the threaded section 1 at the end. The inner diameter of the base pipe 2 is the same as that of the oil pipe. The inflow control chamber 4 is preset on the base pipe 2, and the inflow control box 8 is embedded in it. The hole 5 matched with the nozzle 11 on the back of the control box 8 is used as a passage for the fluid to flow into the base pipe 2. The upper casing 3, the sand control screen 6 and the lower casing 7 are connected by welding, and the upper casing 3 and the lower casing 7 are close to the sand ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com