Power takeoff device for oppositely-arranged double hydraulic pumps of diesel engine

A technology of hydraulic pumps and diesel engines, which is applied in the direction of mechanical equipment, machines/engines, etc., can solve the problems of complex design of diesel engine gear trains, the need for overall replacement, and poor reliability, so as to save gear room space, reduce maintenance costs, and facilitate installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

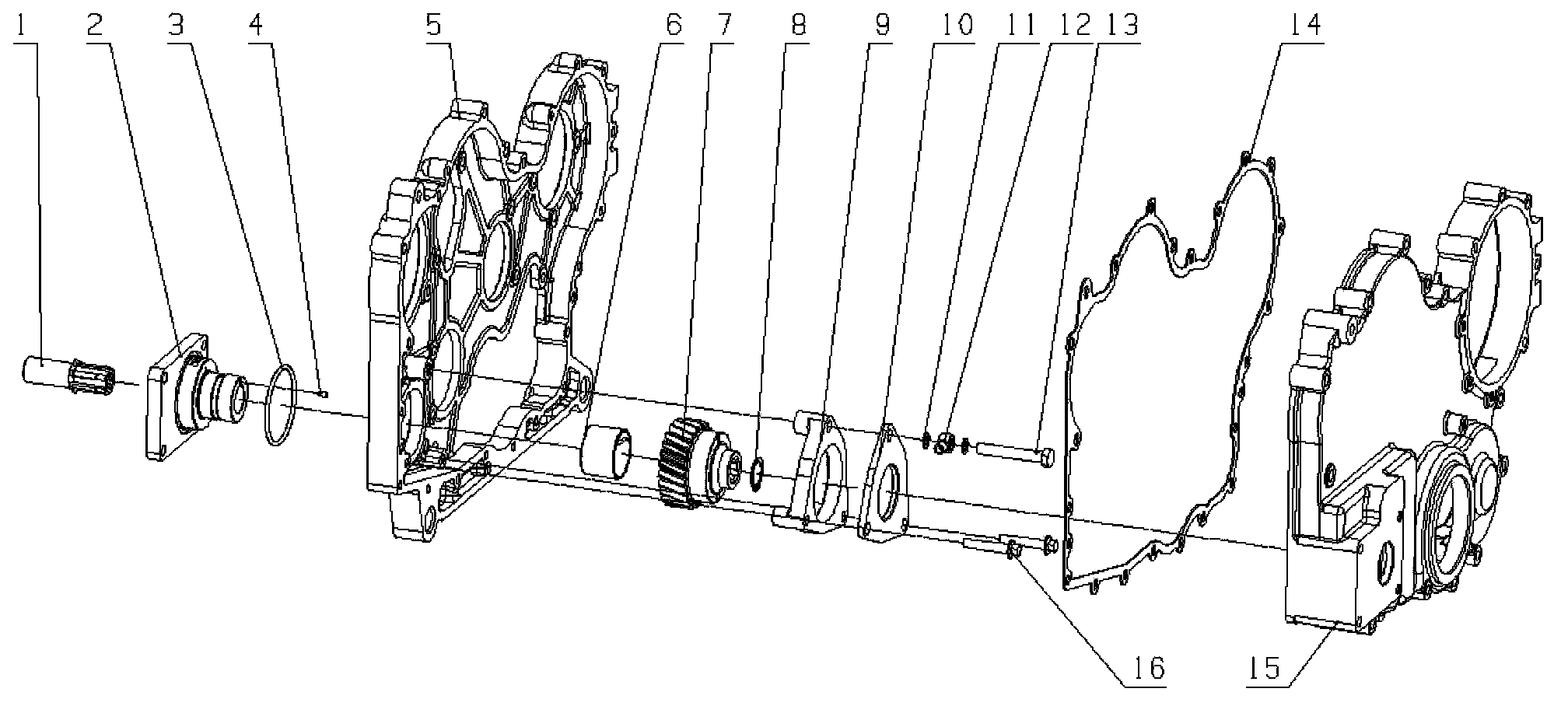

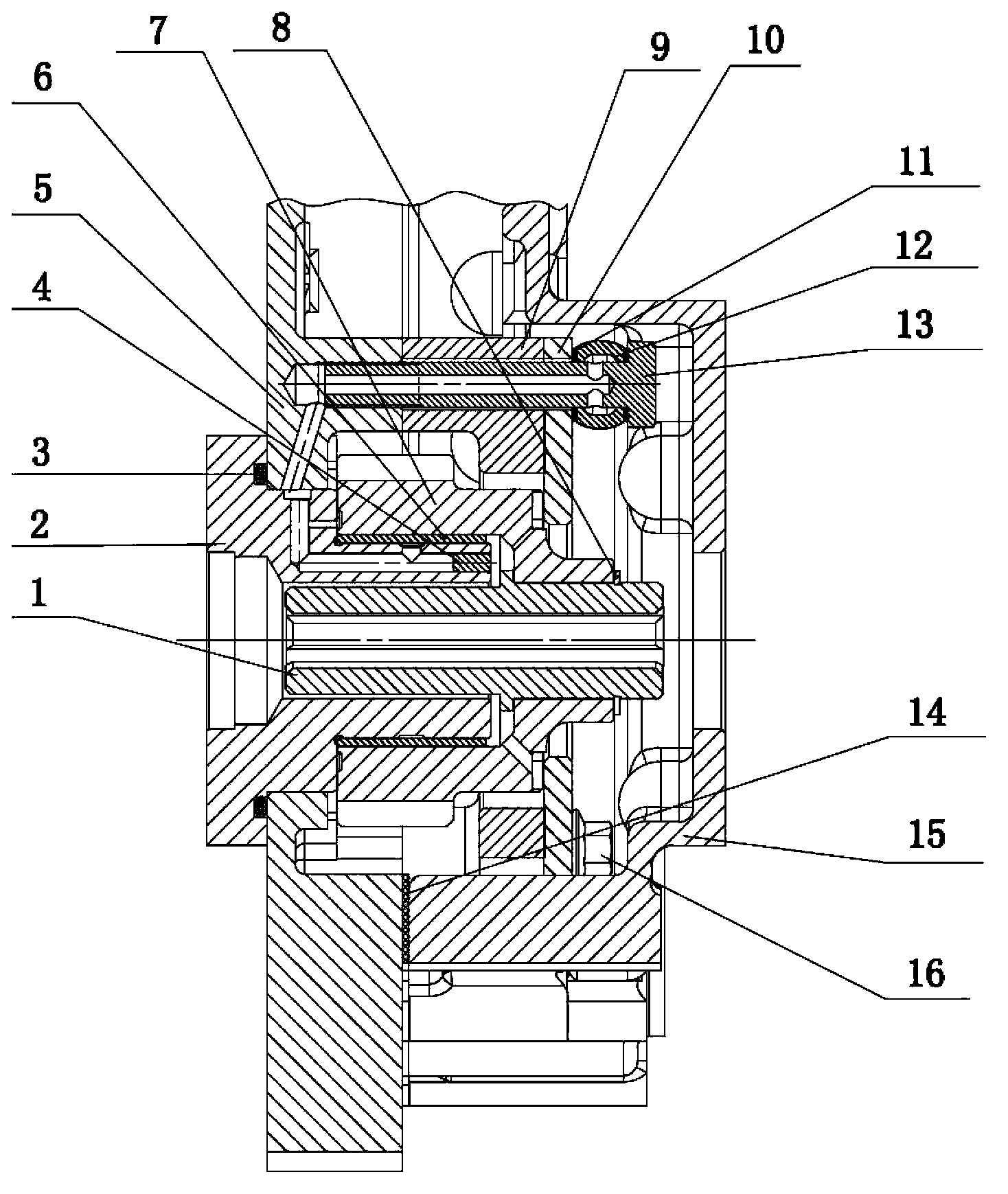

[0019] Attached below figure 1 and figure 2 , describe in detail the specific implementation of the opposed dual hydraulic pump power take-off device for diesel engines of the present invention:

[0020] The spline sleeve 1 is provided with an inner spline and an outer spline, and the outer spline meshes with the inner spline of the hydraulic pump drive gear 7; the hydraulic pump drive gear 7 is press-fitted with a sliding bearing 6 and then fitted on the hydraulic pump gear shaft 2 ; The hydraulic pump gear shaft 2 is fixed on the diesel engine gear chamber 5 by bolts, and the O-ring 3 is used for sealing between the two.

[0021] One end of the outer spline of the spline sleeve 1 is provided with an axial limit convex circle, and the other end is provided with a retaining ring 8 installation groove; the hydraulic pump drive gear 7 is realized through the axial limit convex circle of the spline sleeve 1 and the retaining ring 8 Axial limit of the spline sleeve. The spacer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com