Gas-liquid linkage fast-closing valve system

A gas-liquid linkage and valve technology, which is applied in the pipeline system, gas/liquid distribution and storage, valve details, etc., can solve the problems of increasing components required for hydraulic drive devices, low reliability of hydraulic control circuits, and affecting production activities, etc. , to achieve the effects of compact structure, large valve closing force and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

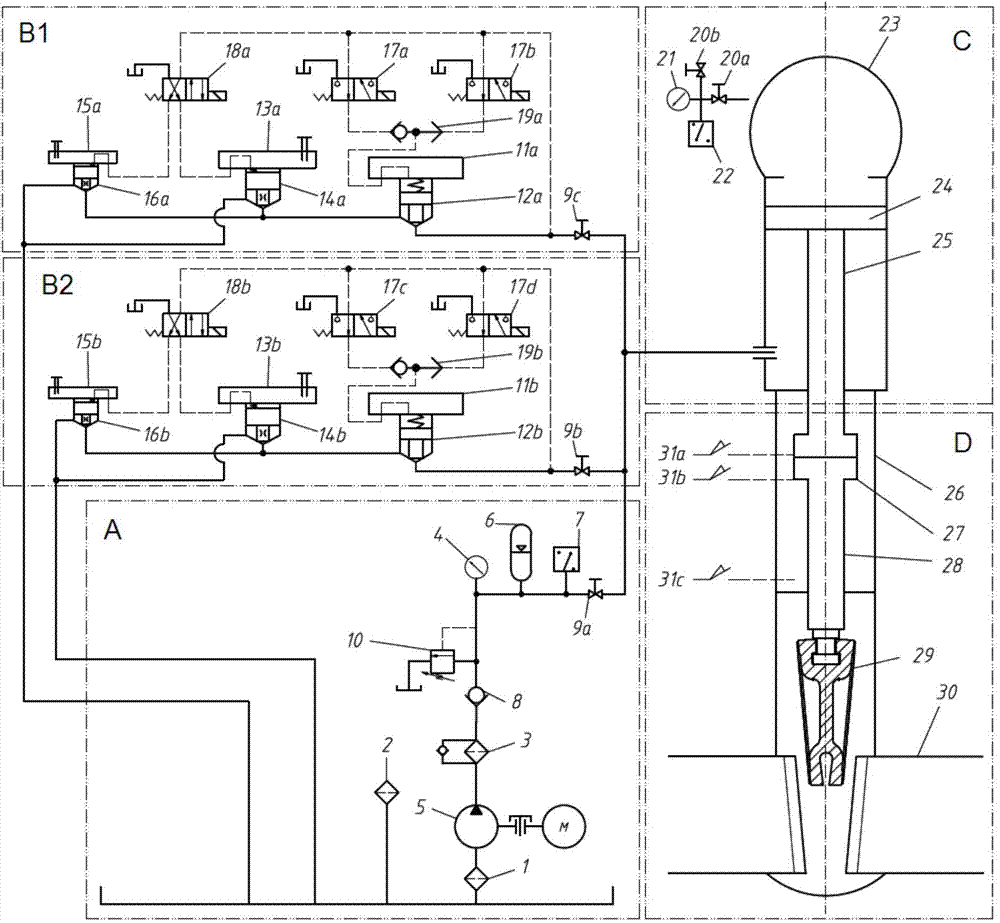

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

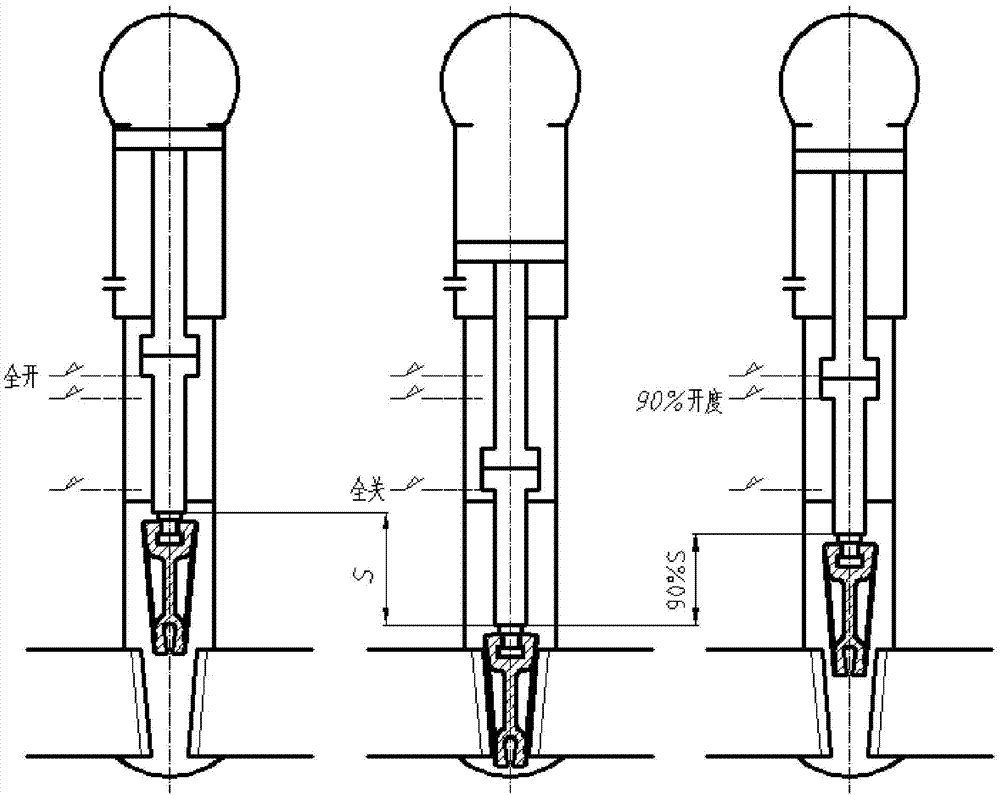

[0030] A gas-liquid linkage quick-closing valve system is installed on the steam pipeline of a power station and is used to control the conduction and blocking of the steam medium in the steam pipeline. First of all, some explanations will be made on the three working positions of the valve and several different working conditions. Such as figure 2 As shown, the three working positions of the valve include:

[0031] Fully open position: At this time, the steam medium in the pipeline is open and can pass through freely.

[0032] Fully closed position: At this time, the steam medium in the pipeline is completely blocked and cannot pass through freely.

[0033] 90% opening position: between the fully open position and the fully closed position, if the distance from the fully open position to the fully closed position is S, then the distance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com