Regulating valve for regulating the hydraulic volume flow

A volume flow, regulating valve technology, applied in the field of regulating valves, can solve the problems of increasing the overall volume and cost of door closers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

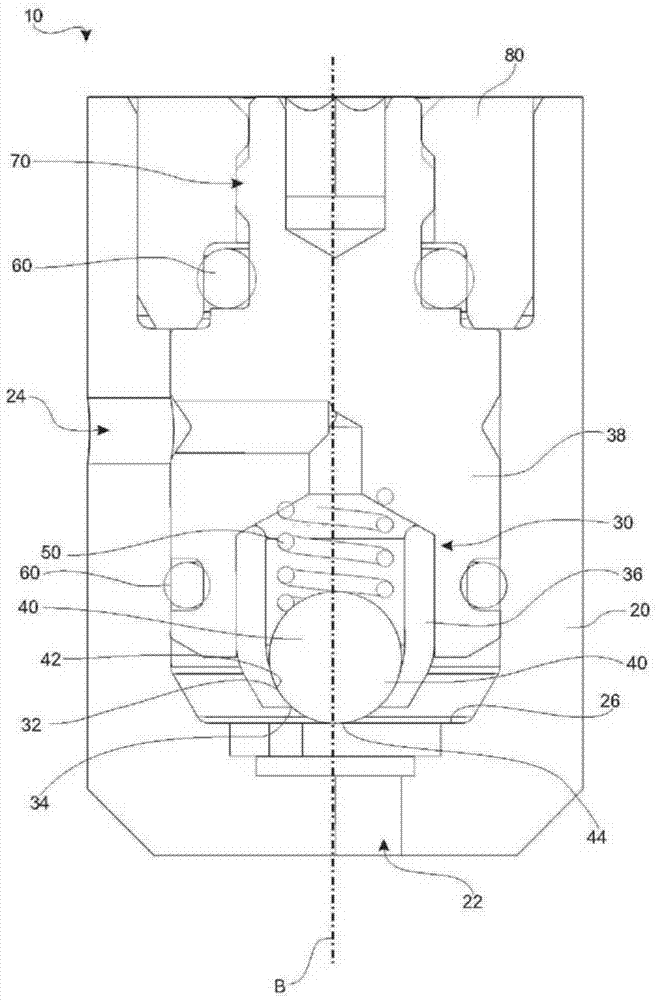

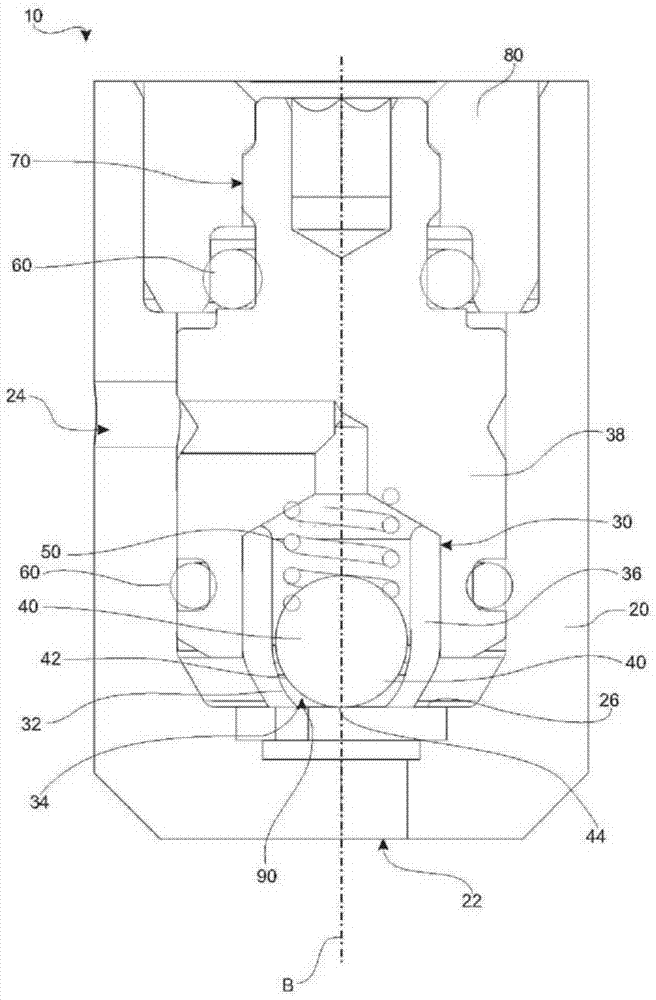

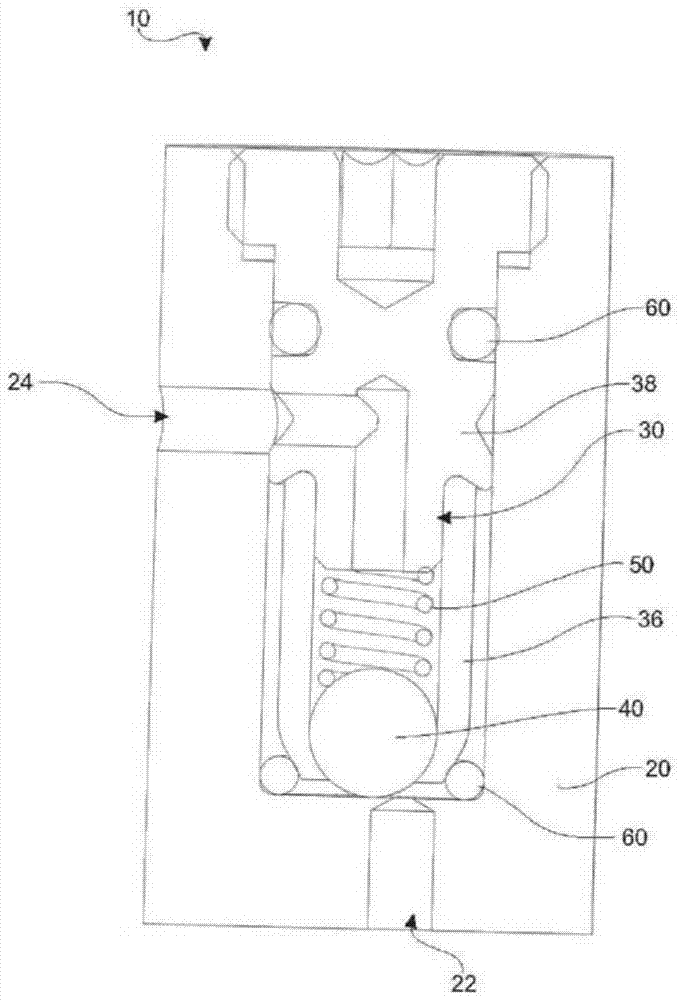

[0042] figure 1 and figure 2 A first embodiment of a regulating valve 10 according to the invention is shown. exist figure 1 In this regulating valve 10 is in a completely closed state, and figure 2 The fully open state is shown.

[0043] Such a control valve 10 is equipped with a pot-shaped and substantially cylindrical valve body 20 . In the interior of such a valve body 20 is accommodated a sleeve 30 which in this embodiment is constructed in two parts. Thus, such a socket 30 is provided by assembling the socket carrier 38 and the socket head 36 . The spring device 50 is supported between the adjustment member 40 and the sleeve carrier 38 of the sleeve 30 . Therefore achieved in figure 1 The adjustment member 40 is loaded with downward spring force. A sealing seat is formed between the adjusting member 40 and the sleeve 30 , which is provided by the contact of the outer sealing surface 42 of the adjusting member 40 with the inner sealing surface 32 of the sleeve 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com