A kind of LED light bar, backlight source and display device

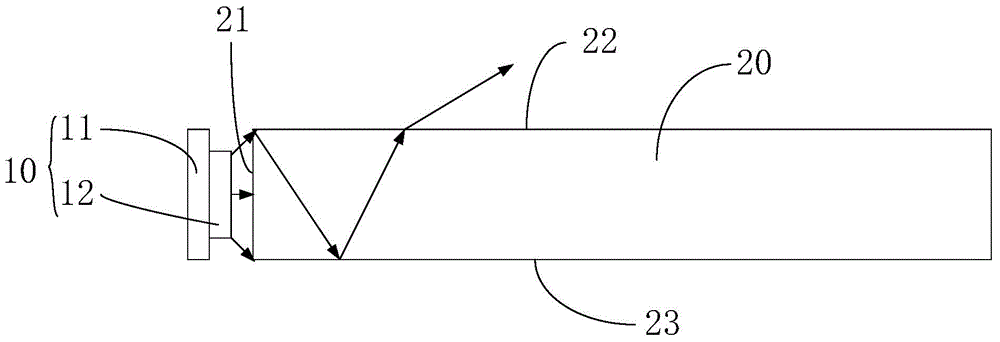

A technology of LED light bar and light emitting surface, which is applied in the field of liquid crystal modules, can solve the problem of less outgoing light, reduce hotspot phenomenon, and improve the effect of insufficient luminous flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

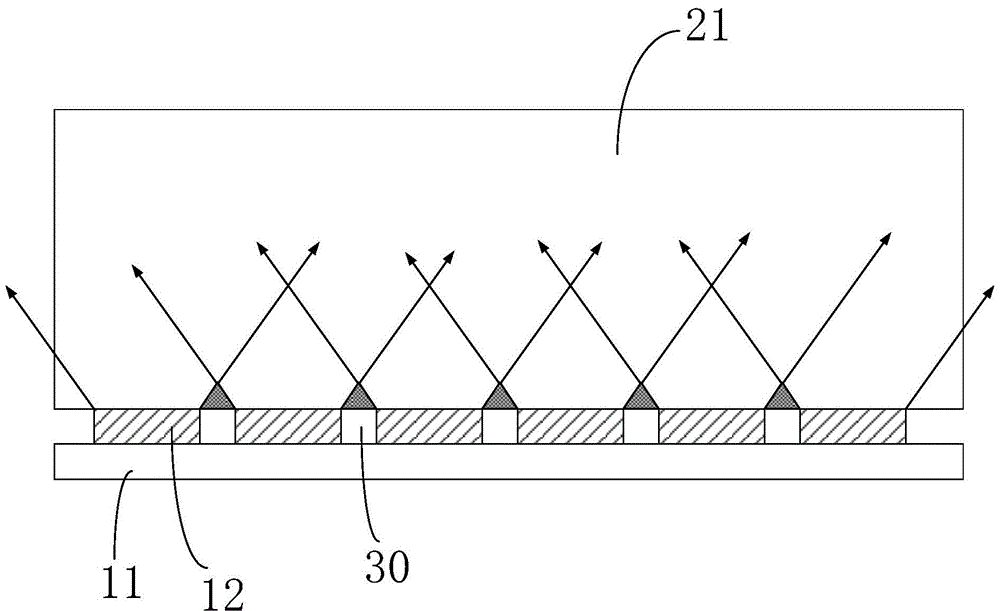

[0050] Such as Figure 4 As shown, in this embodiment, the projection shape of the LED200 on the plane where the circuit board 100 is located is a parallelogram, and the parallelogram includes a first acute angle and a second acute angle arranged diagonally, wherein the first acute angle The corresponding portion forms the first protruding portion 2011 , and the portion corresponding to the second acute angle forms the second protruding portion 2021 .

[0051] In the above scheme, by improving the traditional cuboid LED200 into a parallelogram structure with an acute angle in section, the installation method and installation direction of each LED200 are the same, and the gap 300 between each LED200 and its adjacent LED200 forms an inclined The gap 300 , and each LED 200 and the protruding portion corresponding to the acute angle between its adjacent LEDs 200 cooperate with each other, and the projection on the first projection plane covers the gap 300 . After the LED 200 emit...

Embodiment 2

[0062] Such as Figure 6 As shown, in this embodiment, the projection shape of the LED 200 on the plane where the circuit board 100 is located is a trapezoid, and the trapezoid includes a third acute angle and a fourth acute angle, wherein the part corresponding to the third acute angle forms the The first protrusion 2011 is formed, and the part corresponding to the fourth acute angle forms the second protrusion 2021 . Further preferably, the trapezoid is an isosceles trapezoid.

[0063] In the above solution, the traditional rectangular parallelepiped LED200 is improved into a trapezoidal structure with an acute angle in cross section, and each LED200 is installed in the same way, but the installation directions of two adjacent LED200 are opposite, and they are installed alternately.

[0064] The first side end 201 of each LED200 is arranged close to the first side end 201 of its adjacent LED200, and forms a first gap with the first side end 201 of its adjacent LED200; the s...

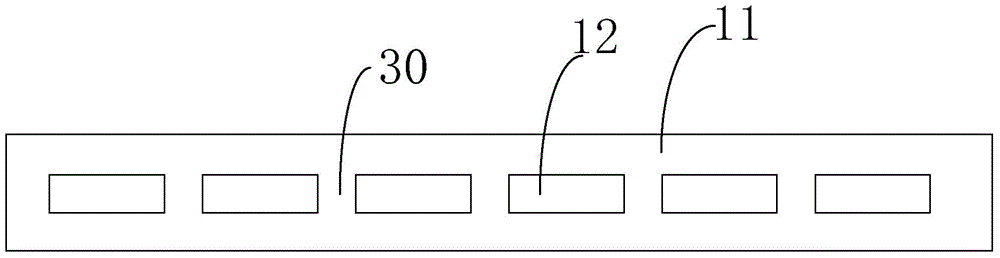

Embodiment 3

[0069] Such as Figure 7 As shown, in this embodiment, the projection shape of the LED 200 on the plane where the circuit board 100 is located is a triangle, and the triangle includes a fifth acute angle and a sixth acute angle, wherein the part corresponding to the fifth acute angle forms the The part corresponding to the sixth acute angle forms the second protrusion 2021 . Further, the triangle is an isosceles triangle.

[0070]In the above solution, the traditional rectangular parallelepiped LED200 is improved to a triangular structure with an acute angle in section, and each LED200 is installed in the same way, but the installation directions of two adjacent LED200 are opposite, and they are installed alternately.

[0071] The first side end 201 of each LED200 is arranged close to the first side end 201 of its adjacent LED200, and forms a first gap with the first side end 201 of its adjacent LED200; the second side of each LED200 End 202 is arranged close to the second s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com