Splicing and fixing structure of block gauge and device adopting the structure

A technology of fixing structure and fixing device, applied in the field of measuring tool inspection, can solve the problems affecting the dimensional accuracy of the block gauge, the low degree of freedom of fitting, and the micro-deformation of the block gauge, and achieves high accuracy, high degree of freedom of fitting, straight line Uniform force and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

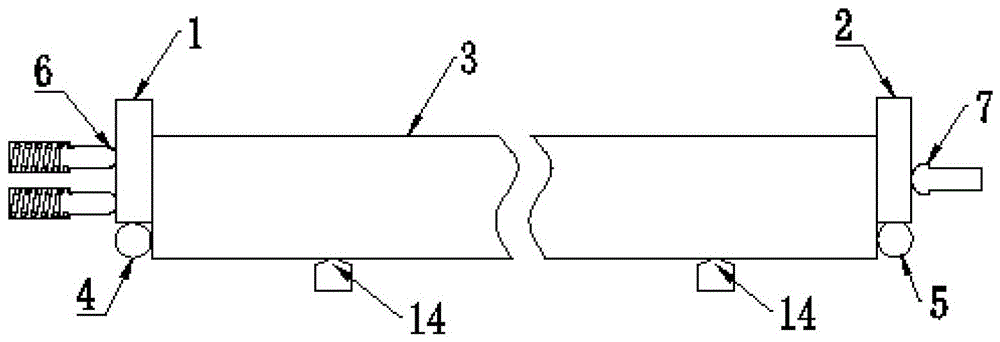

[0035] Embodiment 1: a splicing and fixing structure of a block gauge, such as figure 1 As shown, the third gauge 3 is located between the first gauge 1 and the second gauge 2, and the head end of the third gauge 3 is in surface contact with the end of the first gauge 1, so The end of the third gauge 3 is in surface contact with the head end of the second gauge 2, and a first support 4 for supporting the first gauge is provided below the first gauge 1. Support 4 is a line support, and the second support 5 for supporting the second block gauge is provided below the second block gauge 2. The second support 5 is a line support, and the head end of the first block gauge 1 is provided with There is a first abutting piece 6 for pressing the first gauge 1 towards the direction of the third gauge 3, the first abutting piece 6 is in point contact with the head end of the first gauge 1, so The end of the second gauge 2 is provided with a second abutting member 7 for pressing the second...

Embodiment 2

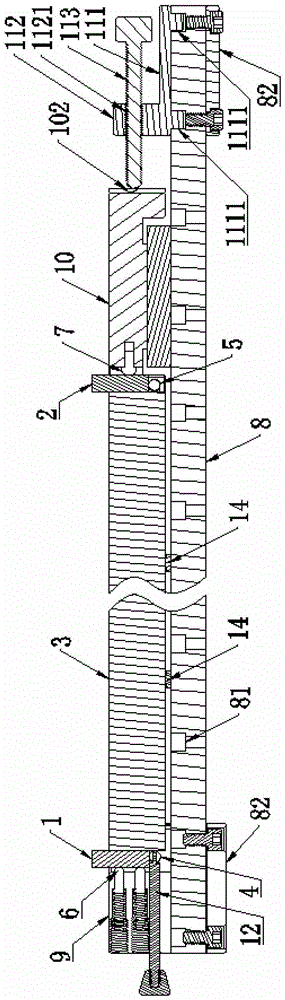

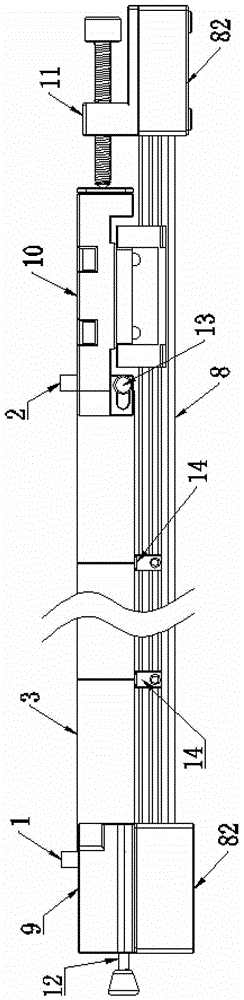

[0038] Embodiment 2: a splicing and fixing device of a block gauge, such as Figure 2 to Figure 6 As shown, the splicing and fixing structure of the block gauge described in Embodiment 1 is also provided with a linear guide rail 8, a first block gauge seat 9, a second block gauge seat 10 and a fastener 11, and the first block gauge The seat 9 and the second block gauge seat 10 are located on the linear guide rail 8, and the first block gauge seat 9 is a fixed block gauge seat fixed on the linear guide rail 8, and the second block gauge seat is A movable block gauge seat capable of moving along the linear guide rail 8, a first slot 91 is provided on the first block gauge seat 9, a second slot 101 is provided on the second block gauge seat 10, the Both the first slot 91 and the second slot 101 are parallel to the linear guide rail 8, and the opening of the first slot 91 is opposite to the opening of the second slot 101, and the first gauge 1 and the first end of the third gauge...

Embodiment 3

[0045] Embodiment 3: This embodiment discloses a splicing and fixing device for a block gauge. The splicing and fixing device for a block gauge in this embodiment is roughly the same in structure as the splicing and fixing device for a block gauge in Embodiment 2. The difference is that the third block gauge 3 of this embodiment is formed by splicing several first single block gauges 31 and several second single block gauges 32 along their nominal measurement directions, and the first single block gauge 31 and the second single block gauge 32 are interlaced, and the adjacent first single block gauge 31 and the second single block gauge 32 are in surface contact, and the head end and the end of the third block gauge 3 are both The first single block gauge 31, the joint of the first single block gauge 31 and the second single block gauge 32 is provided with a third block gauge seat 15, on the third block gauge seat 15 A third slot 151 is opened, and the third slot 151 penetrates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com