A Micro-deformation Control Technology of Split Type Axle Box

A shaft box and micro-deformation technology, which is applied in the field of micro-deformation control technology of split-type shaft box, can solve problems such as inconsistent bearing hole size, increased manufacturing cost, and micro-deformation of the shaft box, so as to improve product qualification rate and reduce Production cost, the effect of optimizing the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

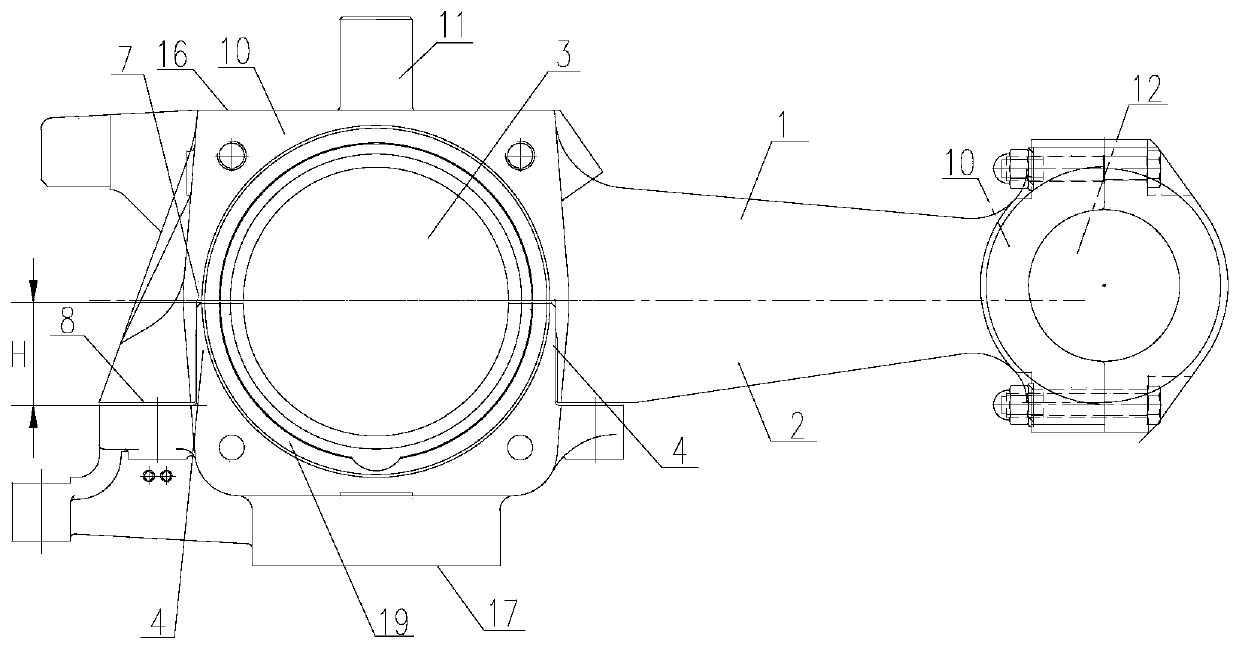

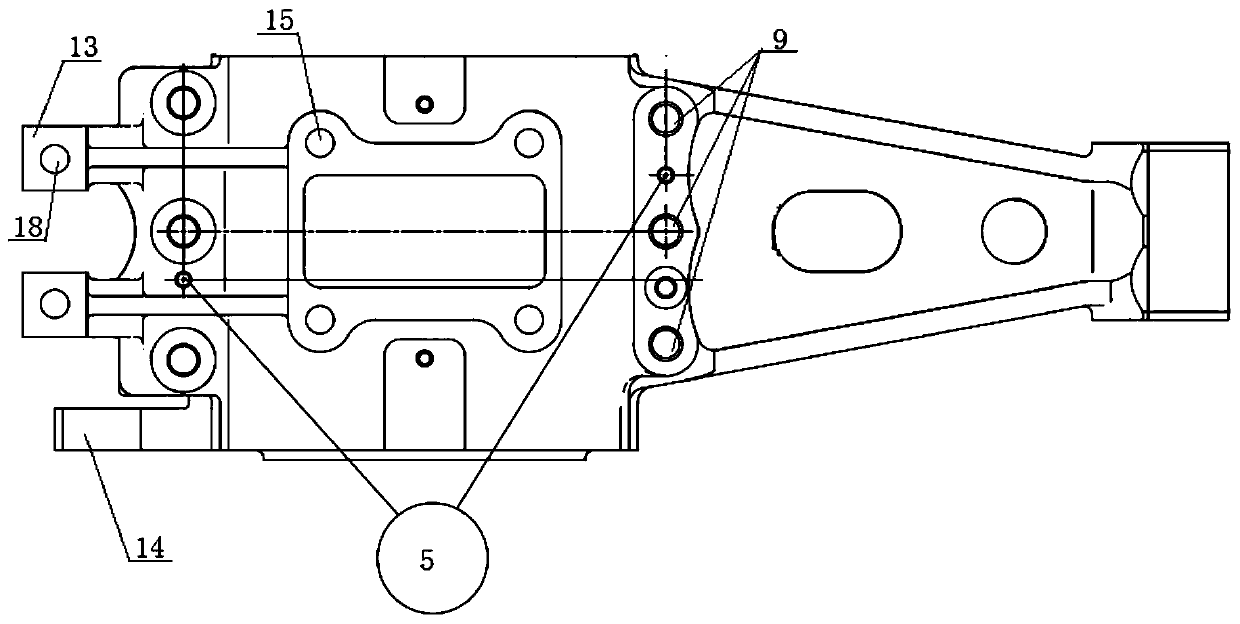

[0035] Such as figure 1 As shown, the present invention provides a split-type axle box micro-deformation control process, the axle box is composed of upper and lower parts, respectively the upper box 1 and the lower box 2, the upper box 1 and the lower box 2 Assembled together by bolts 9 to form a complete axle box body, the middle of the axle box body is the bearing hole 3 for installing the axle, and one end of the axle box body is the node hole 12 for installing the rubber node.

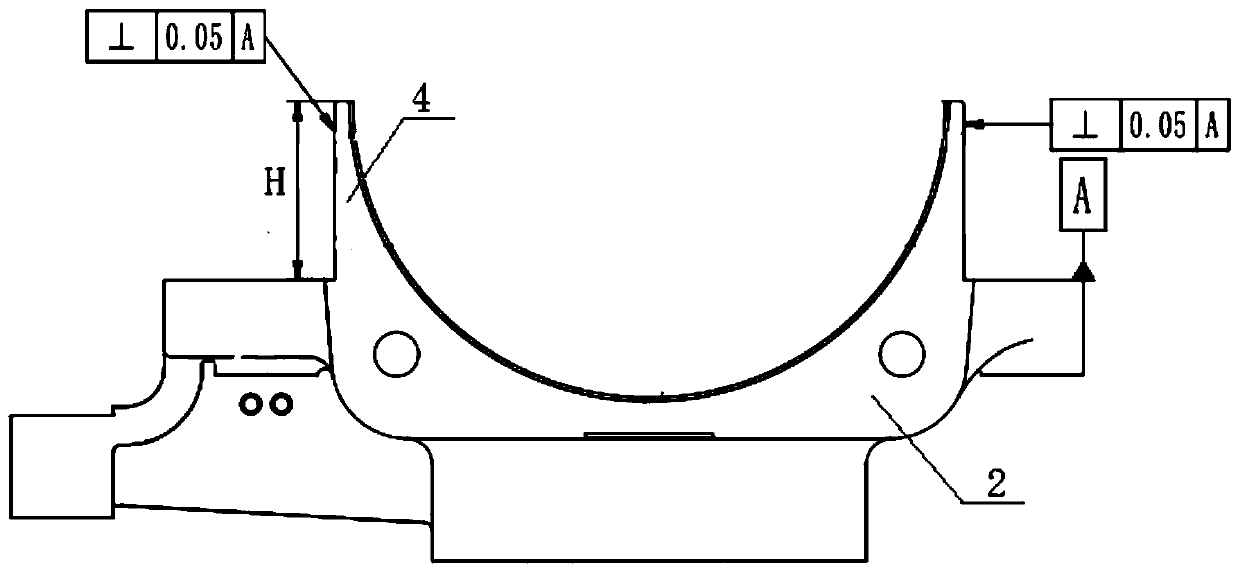

[0036] Such as figure 1 and figure 2 As shown, the two ends of the upper box 1 and the lower box 2 are butted, and there is a gap of about 0.1mm thickness at the joint 7, the wall thickness of the upper box 1 and the lower box 2 is uneven, and the lower box 2 is a thin-walled cantilever 4 structure, the matching gap between the lower box body 2 and the upper box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com