Rapid grouping method for precise elements

A grouping method and component technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as low efficiency, low success rate, repetitive work, etc., and achieve improved grouping stability, improved grouping quality, and liberation The effect of human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

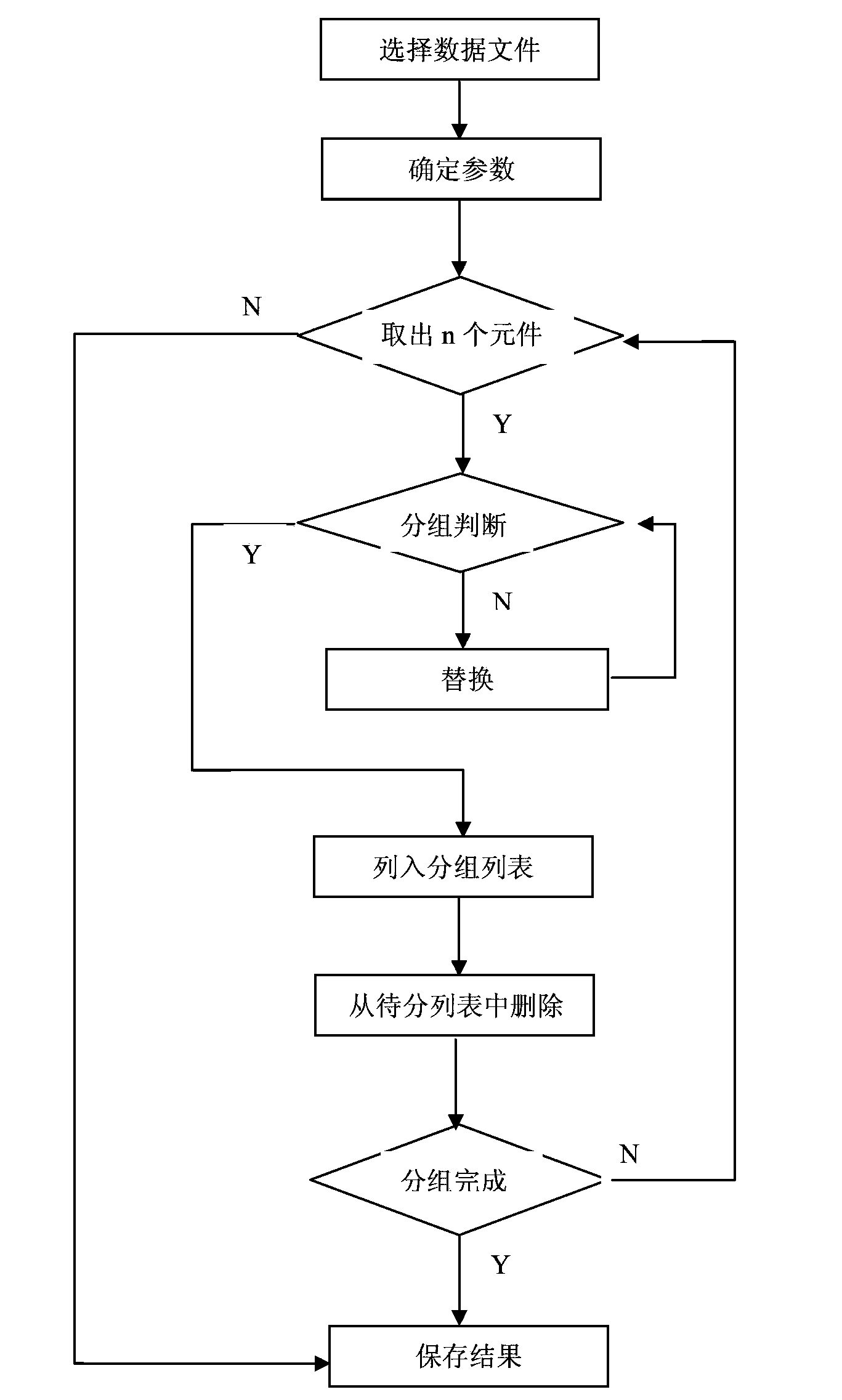

Method used

Image

Examples

example

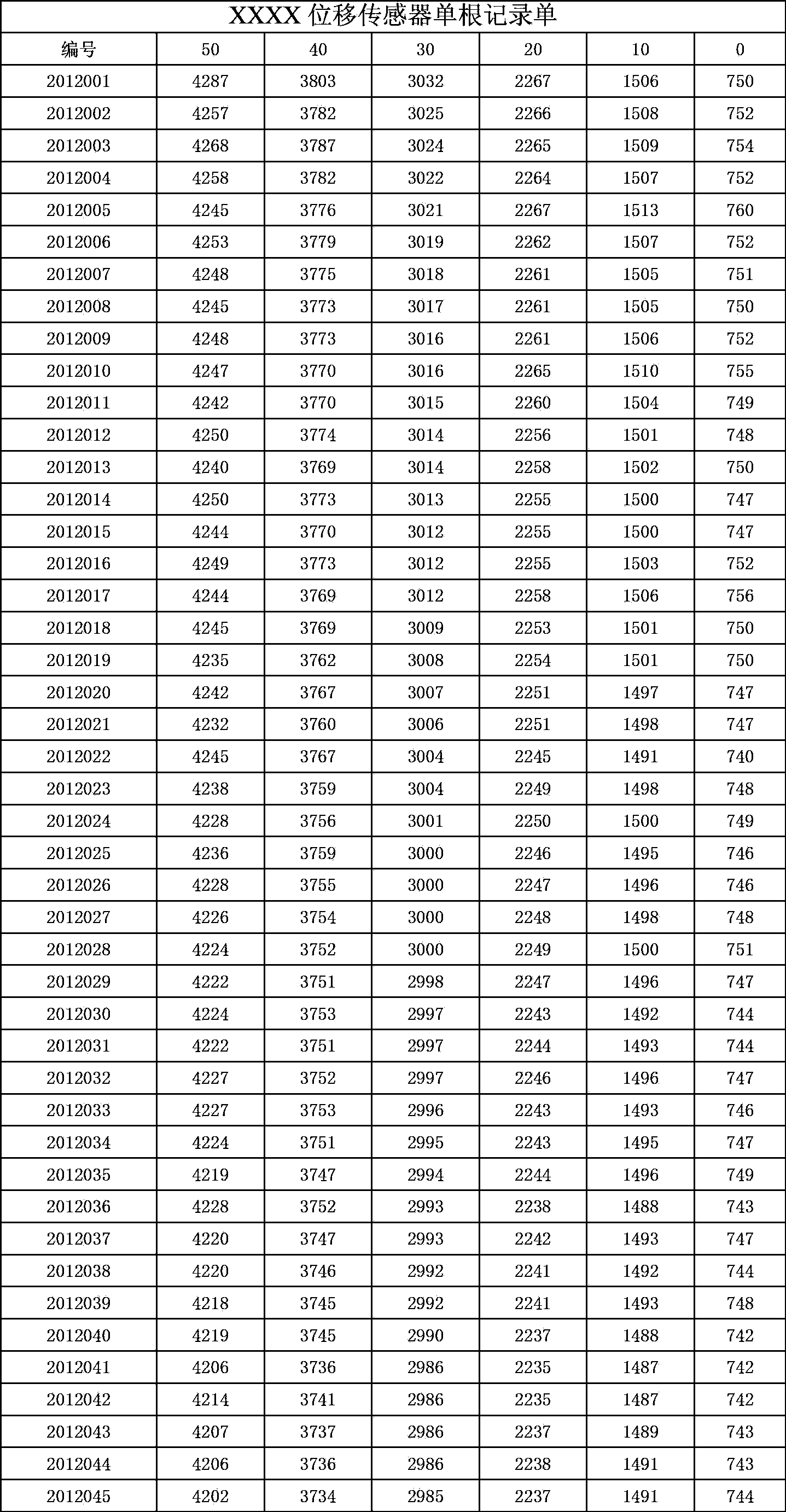

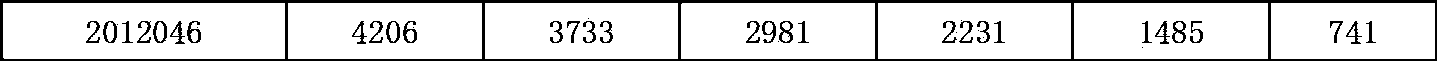

[0021] There are 46 products in this batch to be grouped, each product contains 6 pieces of data that need to be grouped, and 4 products are required to be grouped, and the difference between all corresponding data of these 4 products is not greater than 30, and the serial number is 2012001~2012046.

[0022] Now determine the group base Δn=4, the required tolerance Δ=30, the actual tolerance Δ 1 =15

[0023] Select the data files containing these 46 products, see Table 1;

[0024] First take out 4 precision products numbered 2012001, 2012002, 2012003, 2012004;

[0025] Judge the data of 2012001, 2012002, 2012003, and 2012004, assuming that the result is greater than Δ 1 , does not meet the grouping requirements;

[0026] Randomly take out a precision component from the list to be grouped and randomly replace one and repeat the previous step. Assuming that the combination meets the grouping judgment requirements until 2012006 is used to replace 2012001, then write 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com