A cold processing method for manufacturing full-price pet food and full-price pet food

A technology of pet food and cold processing, applied in animal feed, animal feed, additional food elements, etc., can solve the problems of weakening the nutritional value of commodity grains, destroying product nutrients, and reducing product economic benefits, so as to increase product added value and enhance Nutritious health function, unique effect of internal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1. Raw material ratio: (by weight percentage)

[0038] Carrots, apples and other air-dried or freeze-dried fruits and vegetables (particle size 0.2~5mm) 5.0~25.0; animal and vegetable oil 5.0~15.0; compound antioxidant 8.0; animal and vegetable protein raw materials 15.0~45.0; starch raw materials 13.0~25.0; premixed Material 10.0~20.0.

[0039] 2. Combine 100g~200g of crushed (40~60 mesh) premix, 50g~250g of carrots, apples and other air-dried or freeze-dried fruits and vegetables (0.2~5mm in diameter), 50g~150g of animal and vegetable oils, and 80g of compound antioxidants , 150g~450g animal and vegetable protein raw materials, 130g~250g starch raw materials are fully mixed;

[0040] 3. Condition the mixed raw materials to keep the moisture below 10%;

[0041] 4. The tempered products are processed by cold processing (the temperature is controlled below 60°C and the pressure is about 1.0MPa), and the particle size is 1.0mm~20.0mm;

[0042] 5. Cool and dry the shape...

Embodiment 2

[0044] Embodiment 2 (comparative embodiment)

[0045] The traditional full-price pet food processing method is the wet extrusion process, and its specific implementation steps are as follows:

[0046] 1. Raw material ratio: (by weight percentage)

[0047]Vitamin 2.0~10.0; compound antioxidant 8.0; animal and vegetable protein raw material 10.0~40.0; starch raw material 8.0~25.0; premix 5.0~20.0; animal and vegetable oil 8.0~15.0.

[0048] 2. After crushing (40~60 mesh), 50g~200g premix, 20g~100g various vitamin nutrients, 80g compound antioxidant, 100g~400g animal and vegetable protein raw materials, 80g~250g starch raw materials are fully processed mix;

[0049] 3. Carry out tempering, the tempering temperature is generally controlled at 80~95°C, and the moisture content of the material is above 20%;

[0050] 4. After puffing, the puffing temperature is as high as 120~135℃, the moisture is about 30%, and the pressure is 2.6~3.0MPa.

[0051] 5. After drying process, usuall...

Embodiment 4

[0053] Embodiment 4. The mensuration of product composition

[0054] Get the sample of above-mentioned embodiment 1 and 2, measure the loss rate of vitamin, added microorganism preparation and enzyme activity respectively.

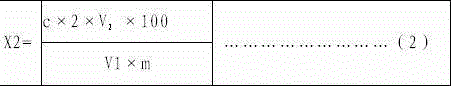

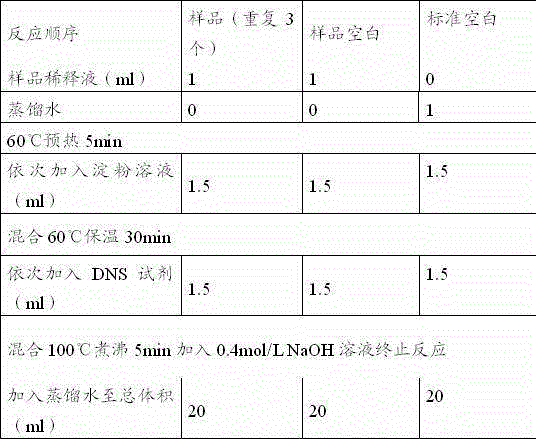

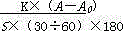

[0055] The vitamin content was measured by chromatography, the microbial activity was measured by plate colony counting method, and the enzyme activity was measured by spectrophotometry, and compared with the added content, the loss rate was calculated. Among them, the vitamin content is a quantitative measurement, and the microbial and enzyme activity is a qualitative measurement.

[0056] Determination of vitamins:

[0057] The following uses the determination of vitamin K as an example to illustrate the determination of vitamins

[0058] The specific steps for the determination of vitamin K are as follows:

[0059] 1) Sample processing

[0060] Take samples: Grind and pass through a 40-60 mesh sieve.

[0061] 2) Sample extraction

[0062] (1) Weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com