Constant temperature and humidity testing machine

A technology of constant temperature and humidity test and testing machine, which is used in laboratory utensils, heating or cooling equipment, shells or chambers, etc. Shen and other problems, to meet the low flow rate test requirements, the gas flow is uniform, and the effect of avoiding airflow turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

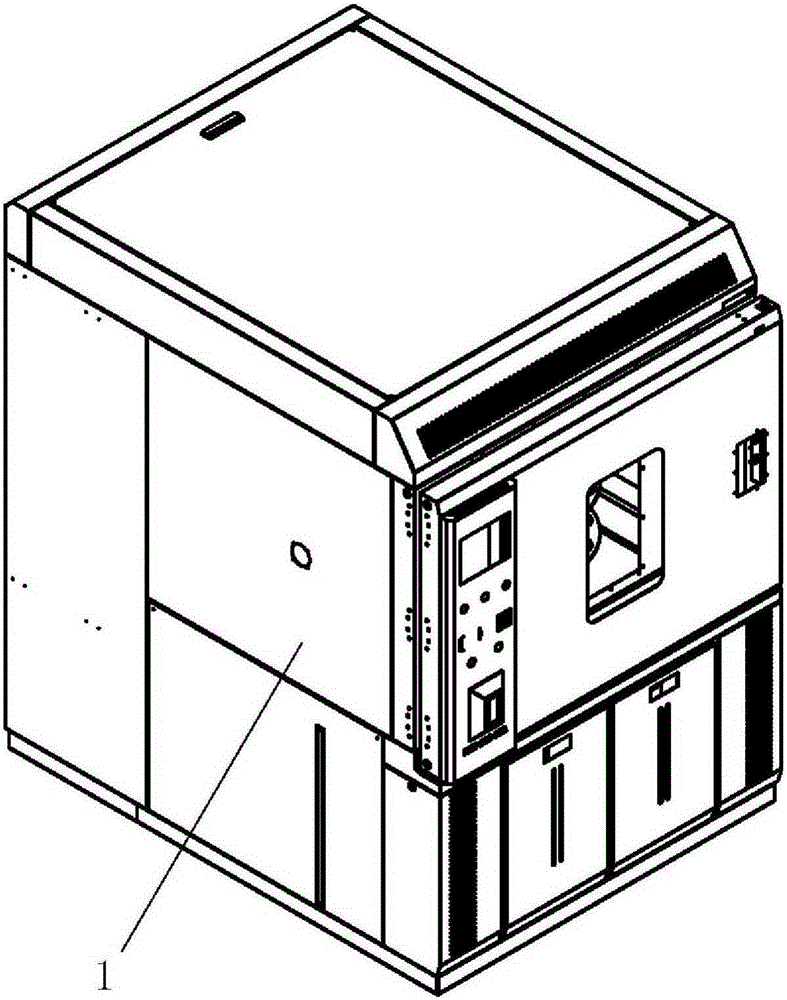

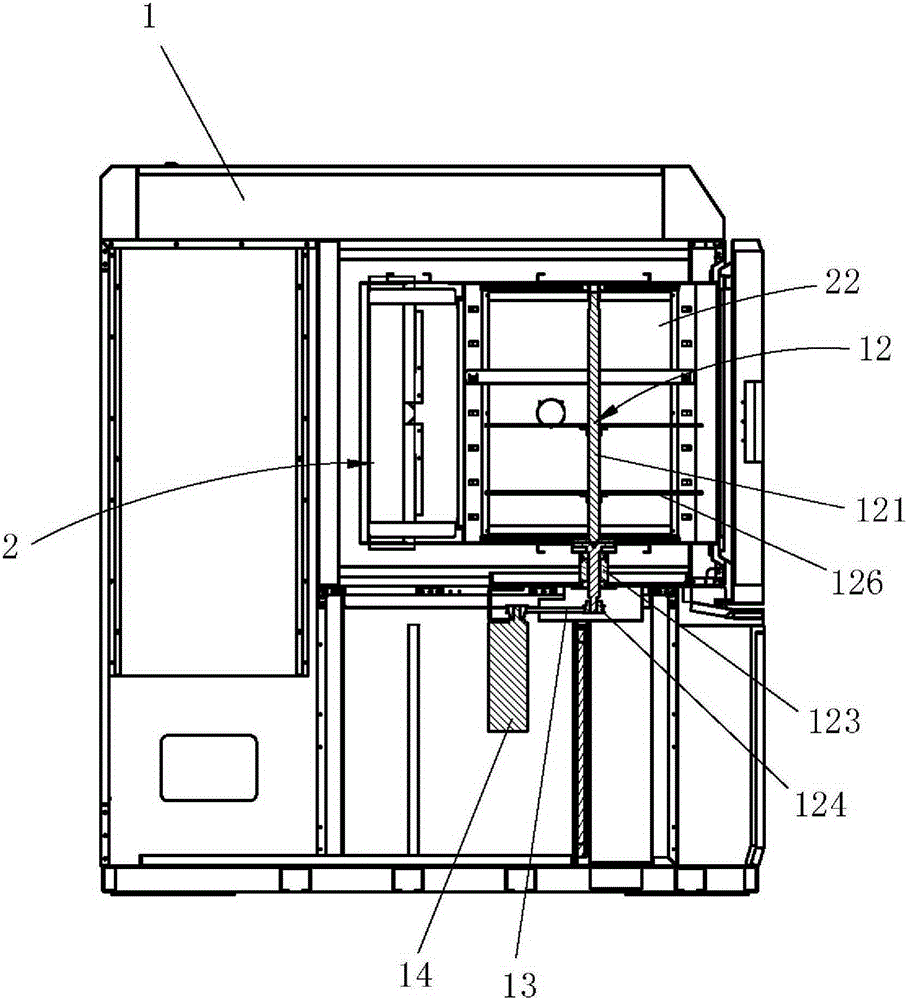

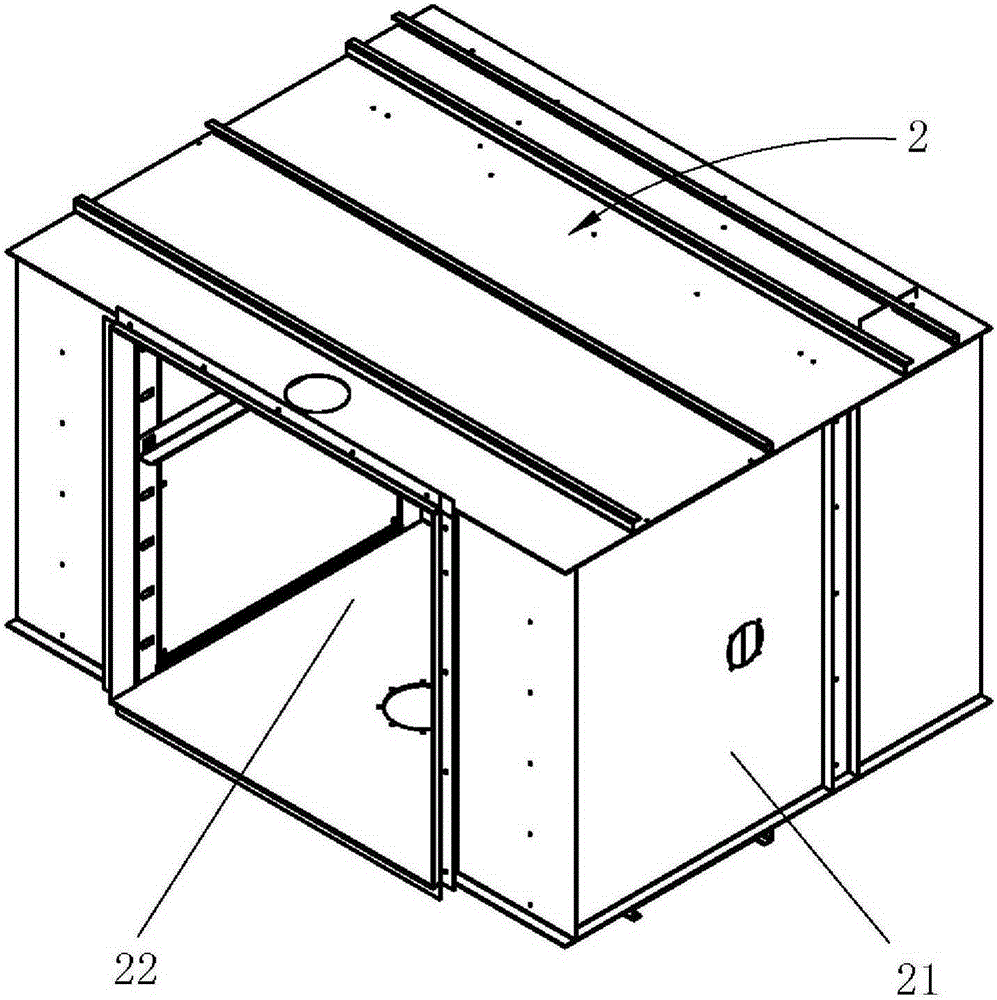

[0029] Please refer to Figure 1 to Figure 7 , a constant temperature and humidity testing machine is shown in the figure, including a testing machine shell 1, a test box 2 is installed inside the testing machine shell 1, and the test box 2 includes a box body 21 and a test chamber arranged inside the box body 21 22. A circulating air duct 23 is formed between the box body 21 and the test chamber 22, and the circulating air duct 23 communicates with the test chamber 22. The interior of the circulating air duct 23 is equipped with an evaporator 3, a heater 4, a humidifier 5 and a circulating air duct. The fan 6, the air inlet and the air outlet of the circulating air duct 23 are respectively equipped with a gas uniform distribution device 7, and the gas uniform distribution device 7 includes a first mesh plate 71 and a second mesh plate arranged in sequence toward the inner direction of the circulating air duct 23 72. The first mesh plate 71 and the second mesh plate 72 are res...

Embodiment 2

[0039] Embodiment 2 of the present invention provides a constant temperature and humidity testing machine, whose structure is mostly the same as that of Embodiment 1 above, and will not be repeated here. Decrease from top to bottom. Such as Figure 9 As shown, in this embodiment, the second screen unit 72 includes a first screen unit 721 , a second screen unit 722 and a third screen unit 723 arranged in sequence from top to bottom. Wherein, the first screen unit 721, the second screen unit 722 and the third screen unit 723 are integrally formed, the number of mesh holes of the first screen unit 721 is greater than the number of the second screen unit 722, and The number of meshes of the second screen unit 722 is more than the number of meshes of the third screen unit 723, preferably, the first screen unit 721, the second screen unit 722 and the third screen unit 723 The meshes have the same pore size.

[0040] In summary, during work, the gas in the test chamber 22 enters t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com