Maintenance device for chain buckle of double-chain conveying machine

A conveyor and chain buckle technology is applied in the field of maintenance devices for double chain conveyor chain buckles, which can solve the problems of high labor intensity, fast wear, and trouble.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

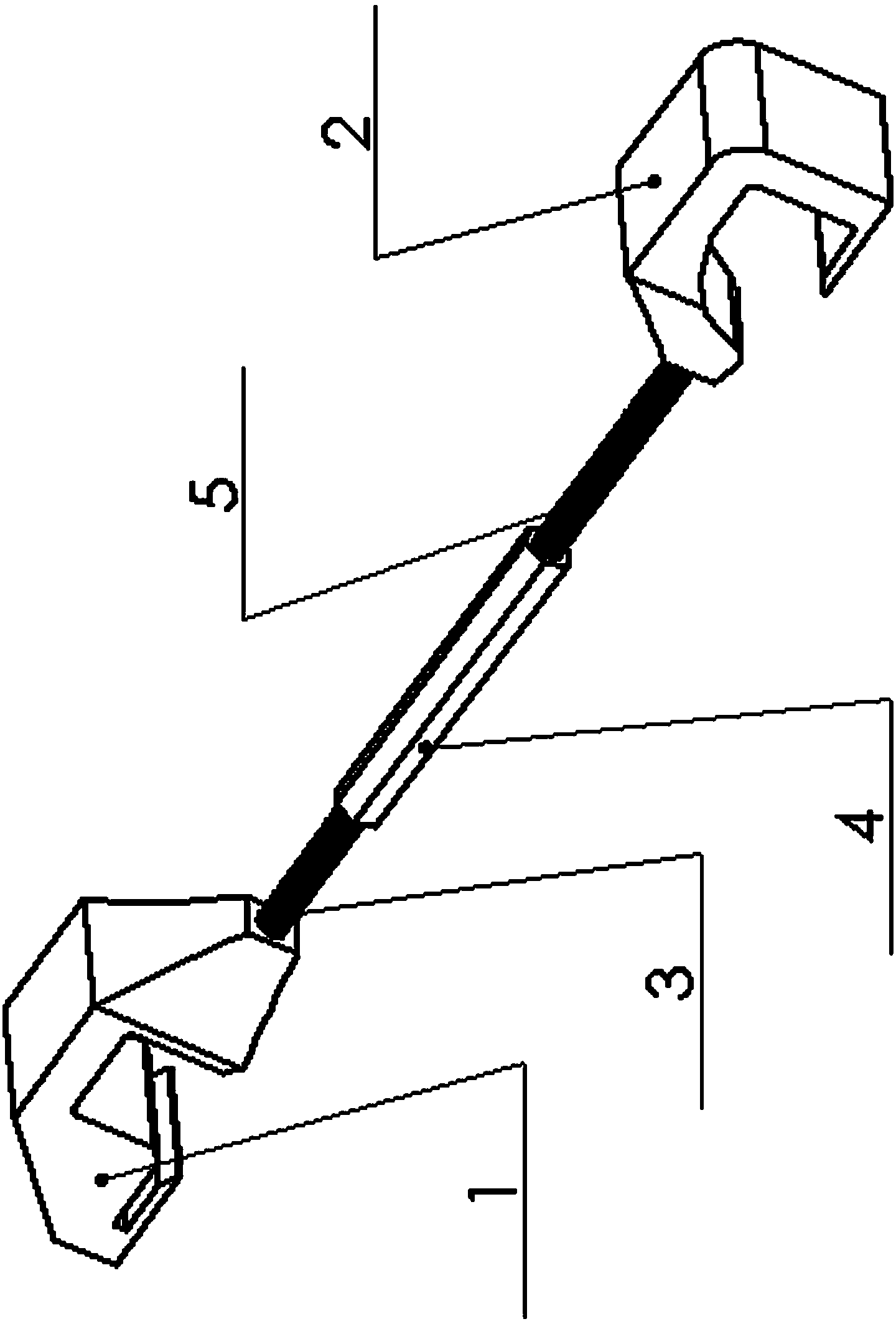

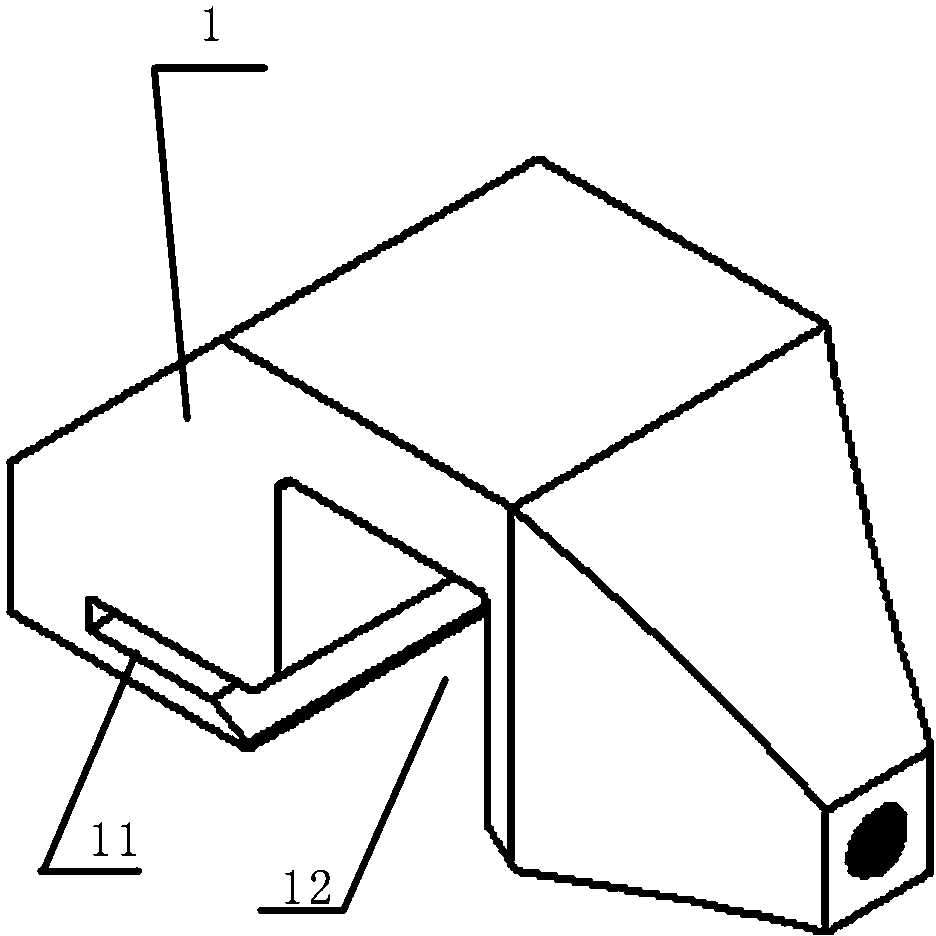

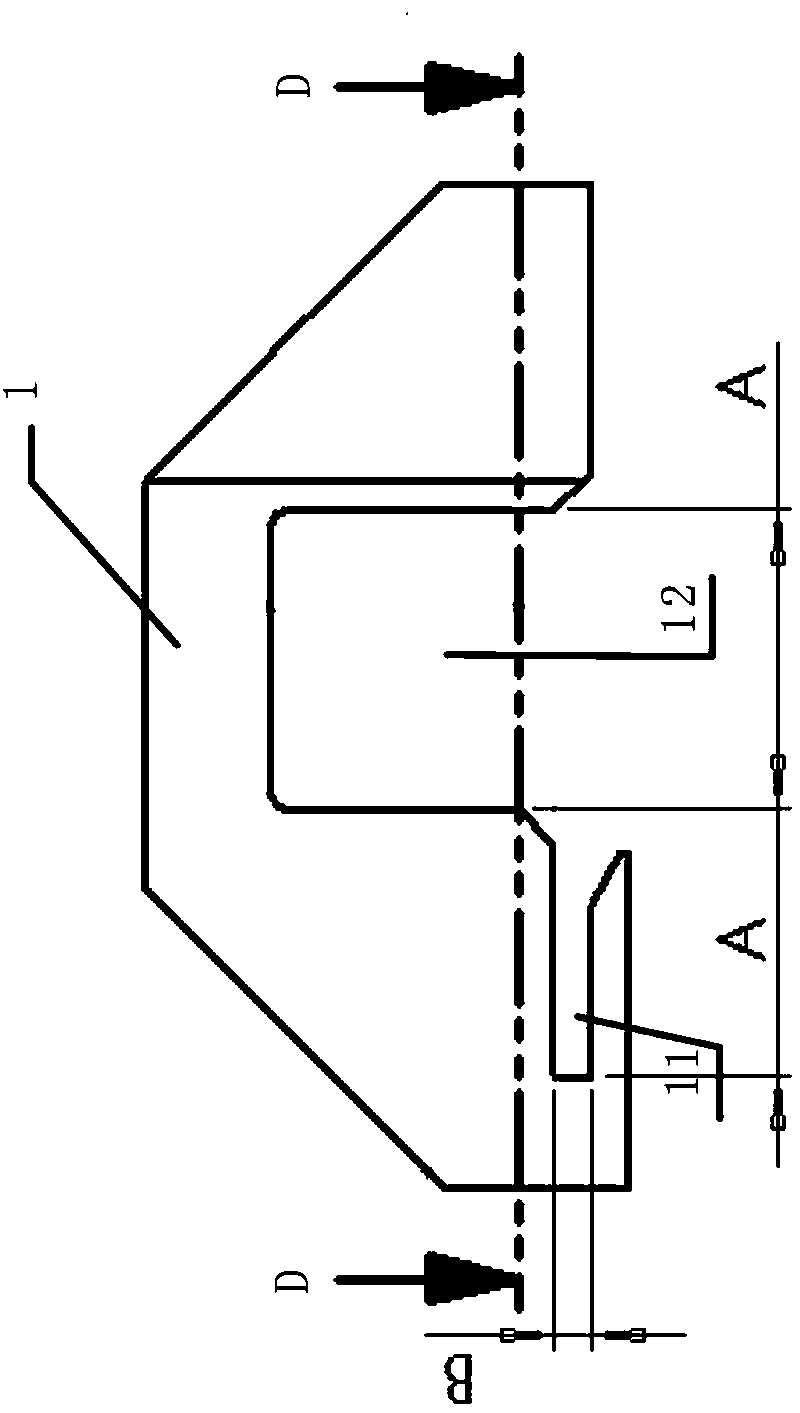

[0027] The device of the present invention can be used in two pairs, or one can be used. It is first installed between two adjacent retaining bars (angle iron retaining bars) that need to maintain the chain buckle in the Nanyou double chain conveyor. The device includes positive pull Buckle, reverse buckle, screw rod and hexagonal nut sleeve, etc., the forward buckle and reverse buckle fasten two adjacent retaining strips respectively, and design two non-through holes on the forward buckle and reverse buckle respectively The screw holes are designed to install two screw rods on the screw holes of the forward pull buckle and the reverse pull buckle respectively, and a hexagonal nut sleeve is designed to connect the two screw rods. By adjusting the hexagonal nut sleeve, the distance between the two adjacent bars The distance between them changes in order to meet the technical requirements for installing the chain buckle and facilitate the maintenance and installation of the chain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com