Device for demounting clutches

A dismantling device and clutch technology, applied to hand-held tools, manufacturing tools, etc., can solve the problems of difficulty in installation and disassembly, high assembly accuracy requirements, damage to the clutch shaft, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

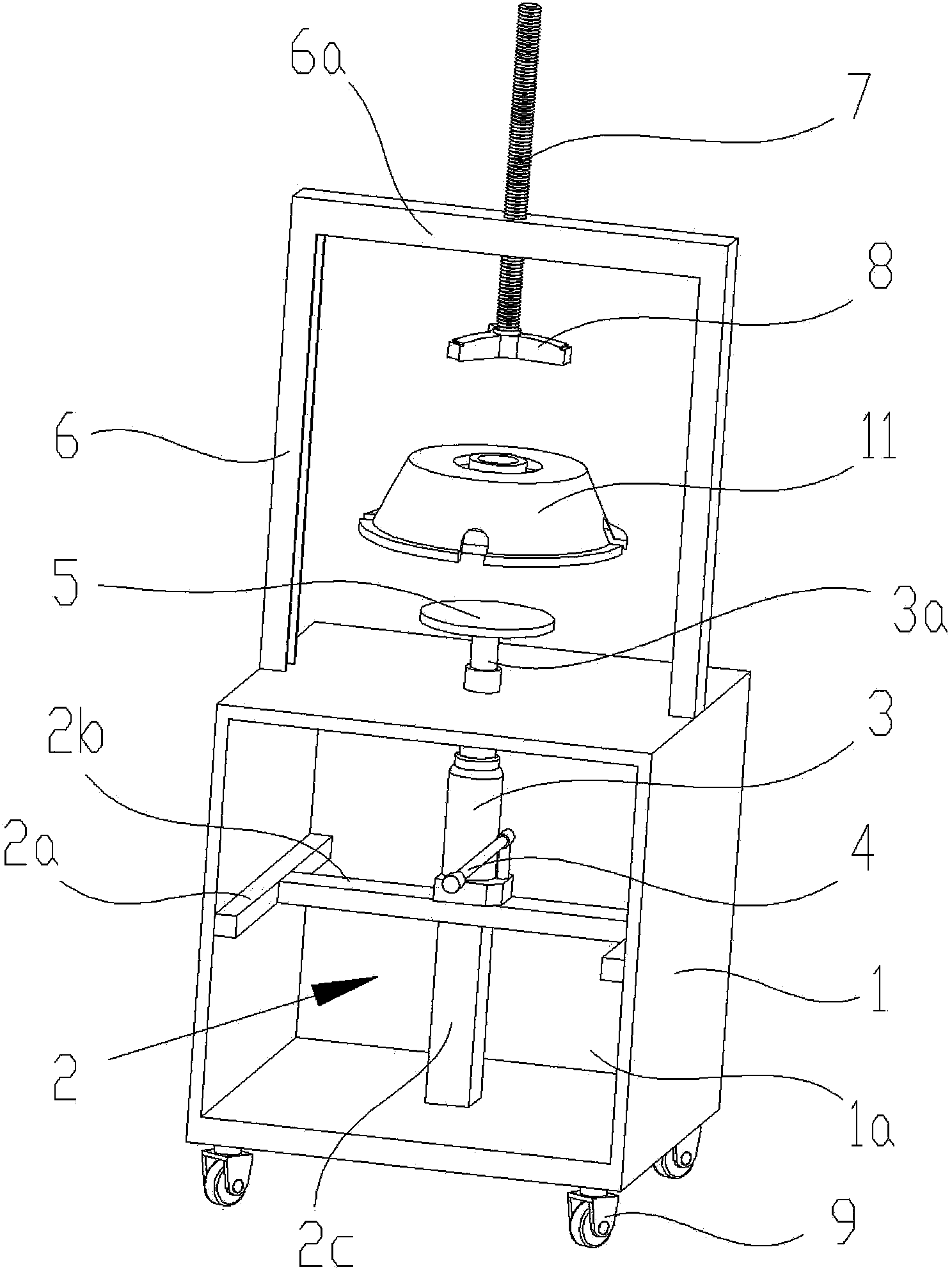

[0014] like figure 1 As shown, a clutch removal device provided by the present invention is characterized in that it includes: a box body 1, the box body 1 is a square box with an open structure on one side, and a bracket 2 is connected in the cavity 1a of the box body 1, A universal wheel 9 is respectively connected to the four corners at the bottom of the box body 1, two columns 6 are symmetrically welded at the center position above the box body 1, and a beam 6a is connected to the top of the two columns 6, and the center of the beam 6a is provided with a screw hole.

[0015] Described bracket 2 comprises two fixed rods 2a, and fixed rods 2a are respectively horizontally symmetrically welded on the inner side surfaces of two symmetrical side walls of box body 1, and a connecting rod 2b is welded between the two fixed rods 2a, between the connecting rods A support rod 2c is welded at the center of the lower part of 2b, and the support rod 2c is welded on the bottom plate of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com