Ink box, ink box chip and light-emitting control method and device of ink box chip

An ink cartridge chip and light-emitting control technology, applied in printing devices, printing, etc., can solve the problems of difficult process requirements and design, high manufacturing cost, etc., and achieve the effect of low process requirements and design difficulty, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

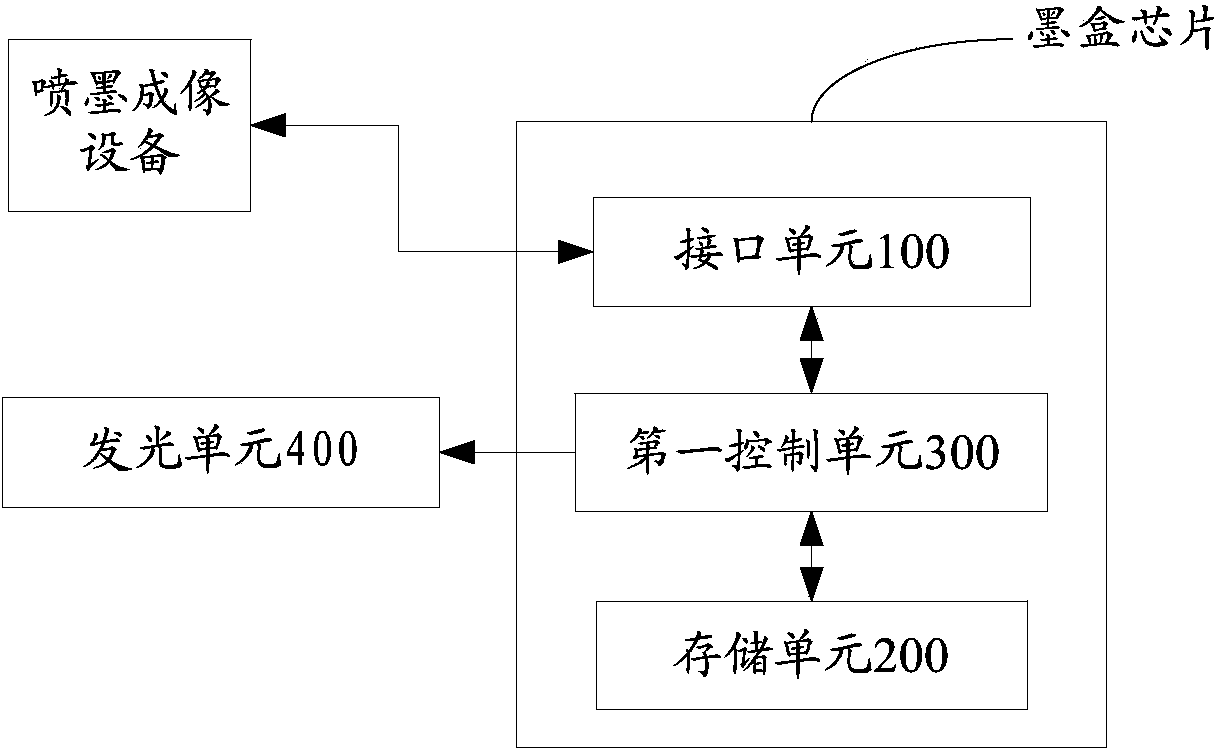

[0076] figure 1 It is a structural schematic diagram of the ink cartridge chip of Embodiment 1 of the present invention, combined with figure 1 The ink cartridge chip of Embodiment 1 of the present invention will be described in detail. Such as figure 1 As shown, the ink cartridge chip includes: an interface unit 100 , a storage unit 200 , and a first control unit 300 . Wherein, the first control unit 300 is respectively connected with the interface unit 100 and the storage unit 200 for realizing signal transmission and control.

[0077] Wherein, the interface unit 100 is used to realize the connection between the ink cartridge chip and the inkjet imaging device;

[0078] The storage unit 200 is used for storing the information of the state of the ink cartridge;

[0079] The first control unit 300 is used to determine whether the inkjet imaging device is currently in the stage of prompting the state of the ink cartridge when the inkjet imaging device starts to supply power...

Embodiment 2

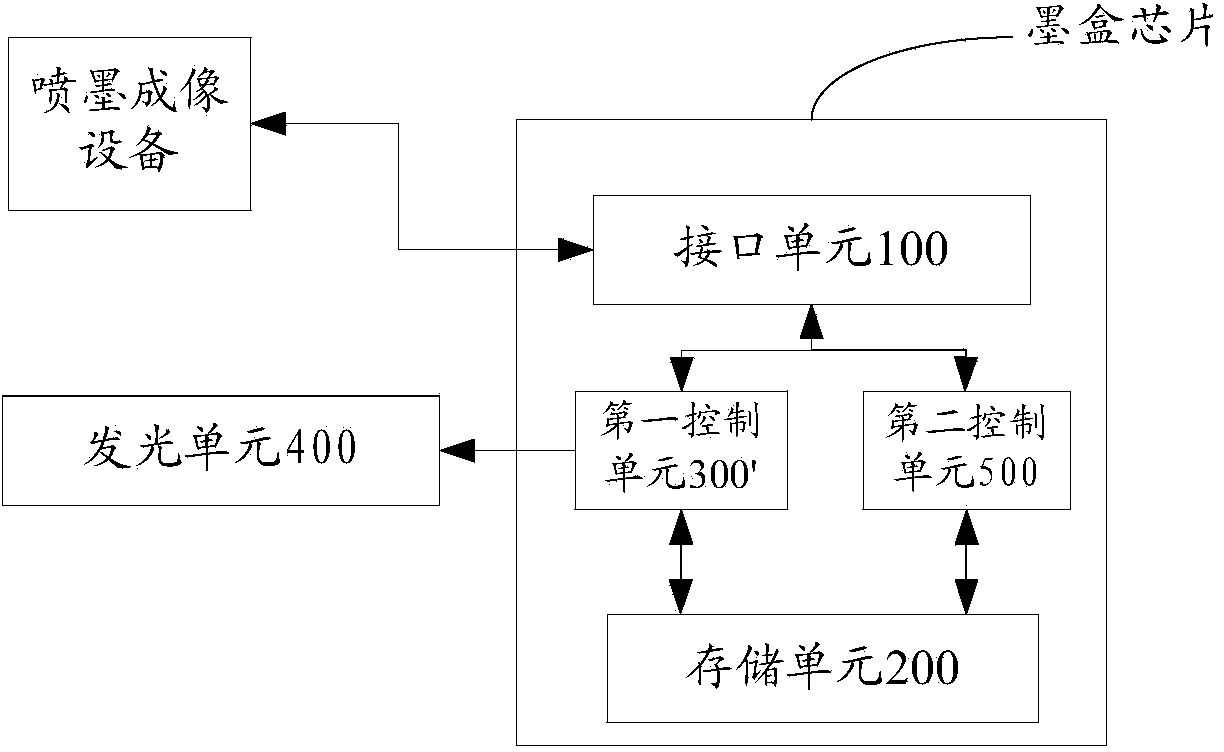

[0118] The ink cartridge chip described in Embodiment 2 has many similarities with the ink cartridge chip described in Embodiment 1. For the sake of brevity, this embodiment focuses on the differences. For the similarities, please refer to the description of Embodiment 1.

[0119] Such as figure 2 As shown, the ink cartridge chip described above may also include a second control unit 500, which is connected to the interface unit 100 and the storage unit 200 respectively, and the second control unit 500 is used to The received read-write control instruction sent by the inkjet imaging device executes read-write operations on the storage unit. In this embodiment, the function of the first control unit 300' is only to realize the control operation of the light control command, and not to control the read and write control command. Instead, the second control unit 500 realizes the control operation of the light control command. .

[0120]Based on the ink cartridge chip described...

Embodiment 3

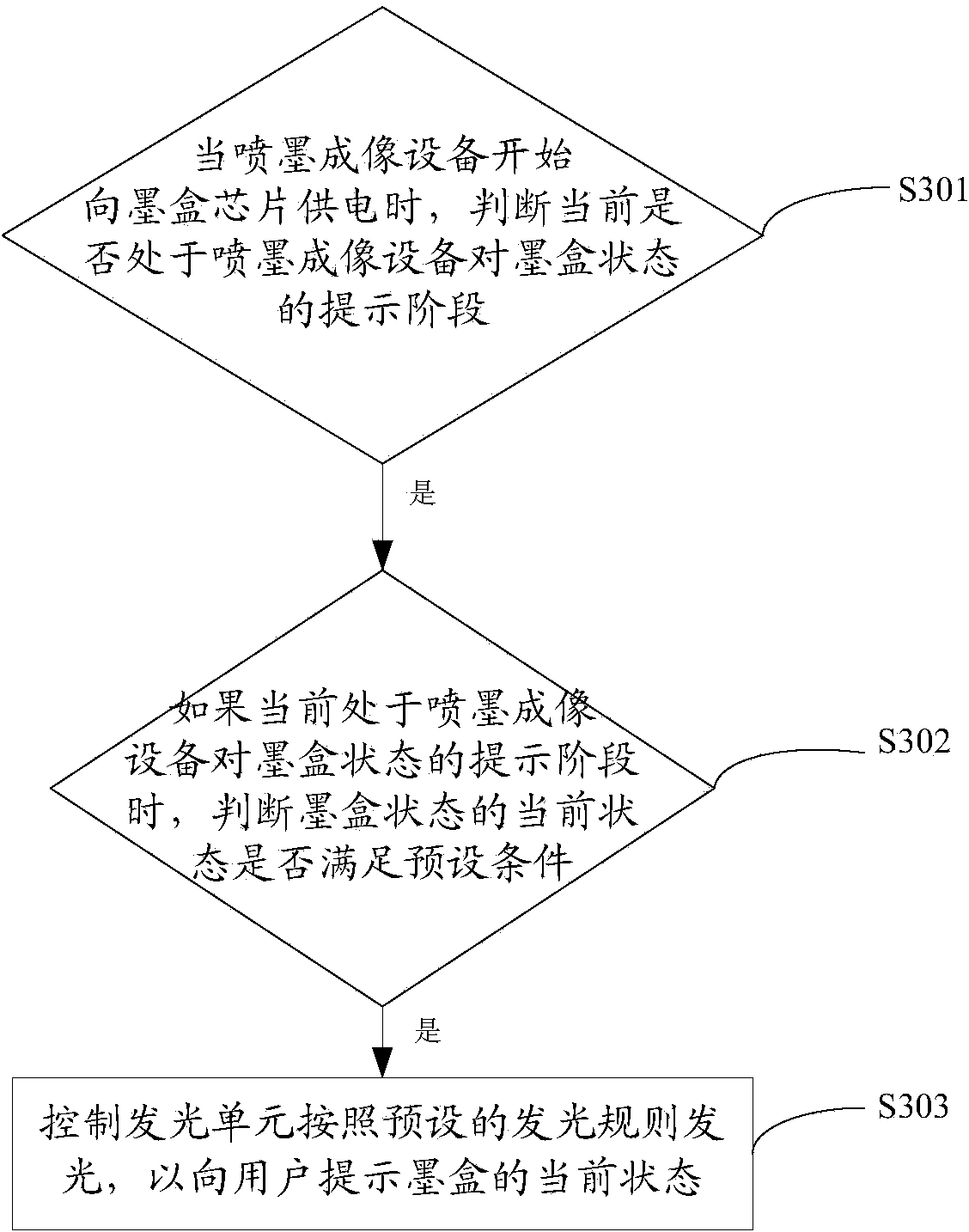

[0123] Such as image 3 As shown, the luminescence control method of the ink cartridge chip comprises the following steps:

[0124] S301. When the inkjet imaging device starts to supply power to the ink cartridge chip, determine whether it is currently in the stage of prompting the inkjet imaging device for the state of the ink cartridge:

[0125] As described in Embodiment 1 or Embodiment 2, the ink cartridge chip described in this embodiment of the present invention includes an interface unit 100 , a storage unit 200 and a first control unit 300 .

[0126] As described in Embodiment 1, there are multiple methods for the first control unit 300 to determine whether the inkjet imaging device is currently in the stage of prompting the state of the ink cartridge. details as follows:

[0127] The first method: by judging whether the type of the light control command is the preset light control command type:

[0128] Specifically, firstly, the interface unit 100 receives the lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com