Energy-saving control device for belt conveyor units

An energy-saving control and belt conveyor technology, which is applied to conveyor control devices, conveyor objects, transportation and packaging, etc., can solve problems such as waste of electric energy and idling of belt conveyors, and achieve the goal of improving transportation efficiency, avoiding idling, and ensuring transportation mode Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] like figure 1 Shown, belt unit of the present invention is connected by belt conveyor 1#, belt conveyor 2#, belt conveyor 3#, belt conveyor 4#, belt conveyor 5# five belt conveyors.

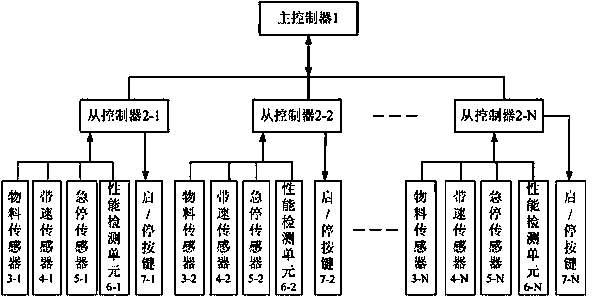

[0021] like figure 2 As shown, an energy-saving control device for a belt unit includes a belt unit composed of multiple belt conveyors, and N shown in the figure is an integer greater than 2. Each belt conveyor is provided with a slave controller; slave controller 2-1, slave controller 2-2 and slave controller 2-N are interactively connected with the same master controller 1; The input end of the controller 2-1 is respectively connected with the output end of the material sensor 3-1, the belt speed sensor 4-1, the emergency stop sensor 5-1 and the performance detection unit 6-1 which are located on the first belt conveyor. The output end of the controller 2-1 is connected with the start / stop button 7-1 of the belt conveyor; the input end of the controller 2-2 is respectively connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com