A single-turbine and twin-turbine switchable air starter motor

An air-start, twin-turbo technology, used in non-variable-capacity engines, machines/engines, mechanical equipment, etc., can solve the problems of cumbersome vane-type air-start motors, high motor noise, and large air consumption, and achieve convenient and fast adjustment. , The effect of low starting pressure and low air consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

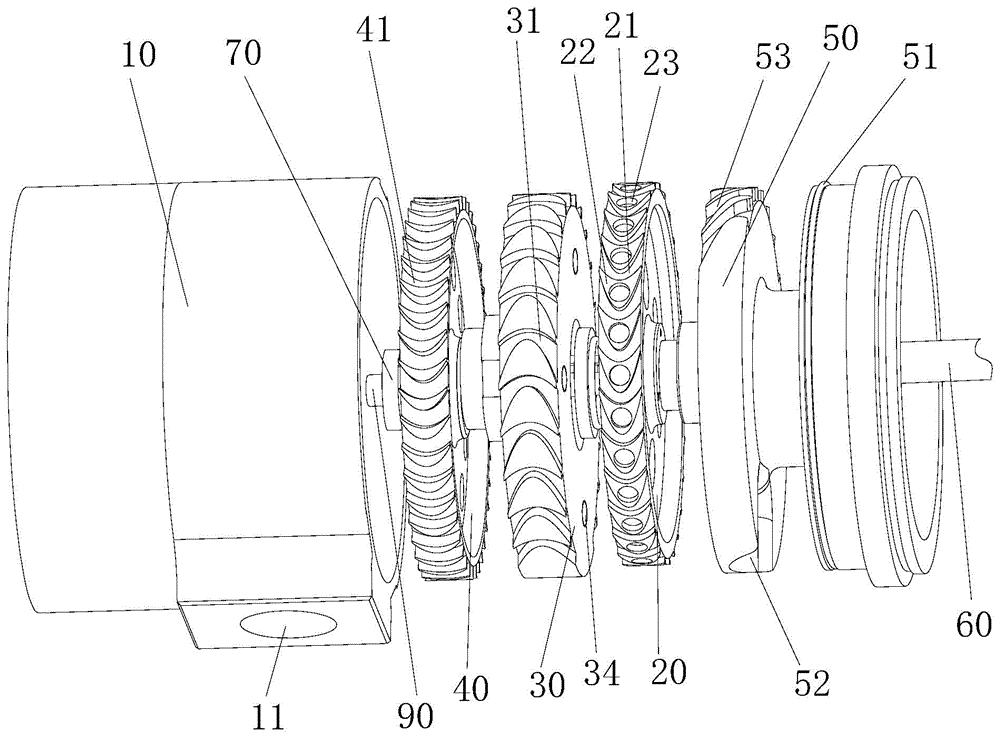

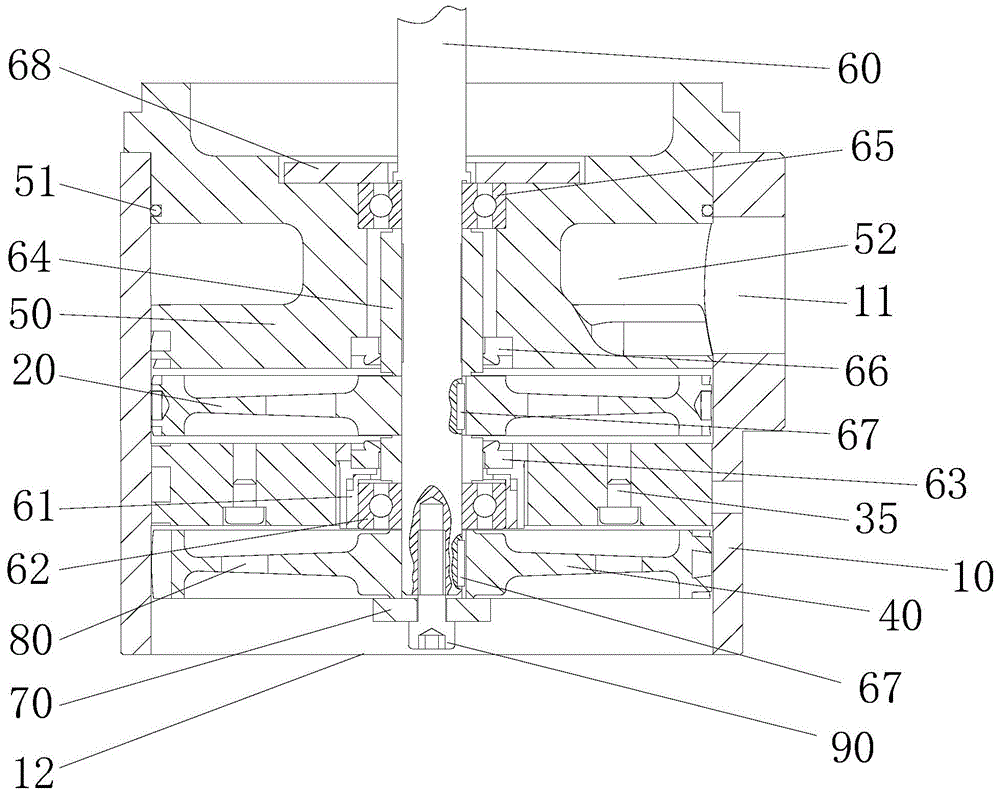

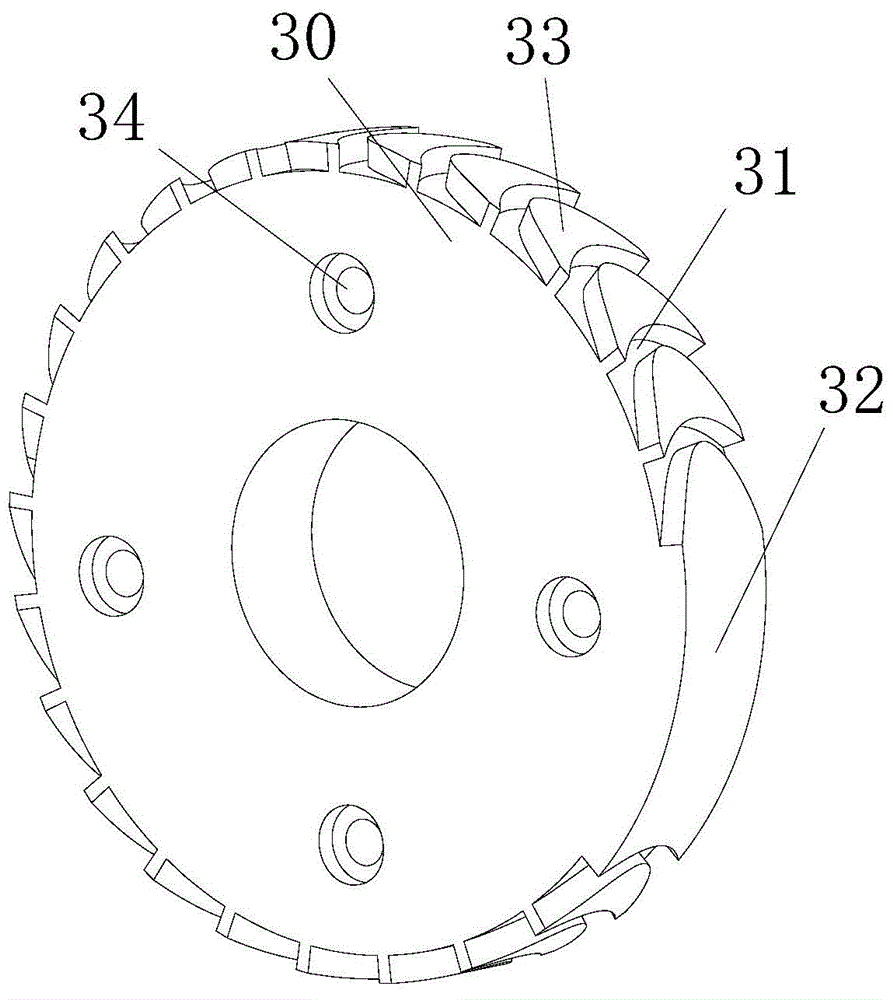

[0034] Such as Figure 1-3 As shown, an air starter motor twin-turbine drive device includes a casing 10 provided with an intake pipe connection port 11 and an exhaust port 12, a primary turbine 20 disposed in the casing 10, a guide wheel 30, and a secondary turbine 40. End cover 50, main shaft 60 and shaft gasket 70. The housing 10 is an axially penetrating housing. The inlet pipe connection port 11 and the exhaust port 12 are arranged front and back, and the inlet pipe connection port 12 is arranged on the shell On the outer wall of the body 10 , an exhaust port 12 is provided at one axial end of the casing 10 .

[0035] Such as Figure 1-2 As shown, the end cover 50 , the primary turbine 20 , the guide wheel 30 and the secondary turbine 40 are sequentially connected to the main shaft 60 , and the primary turbine 20 and the secondary turbine 40 are connected to the main shaft 60 through keys. The shell 10 and the end cover 50 are in clearance fit, and the outer side of the...

Embodiment 2

[0045] This embodiment differs from Embodiment 1 in that: Figure 4 As shown, the injection port 53 and the air intake port 52 are arranged opposite to each other at radial ends of the end cover 50 ; the guide wheel 30 is interference-fitted in the housing 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com