Control system and method for realizing uniform distribution of pulverized coal in direct-blowing pulverizing system

A pulverizing system and evenly distributed technology, applied in the combustion method, controlling combustion, adjusting fuel supply, etc., to simplify the work process, improve safe operation, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below.

[0027] The invention provides a control system for uniform distribution of coal powder in a direct-blown pulverizing system, which includes a flow rate monitoring unit, a concentration monitoring unit and an adjustment processing unit.

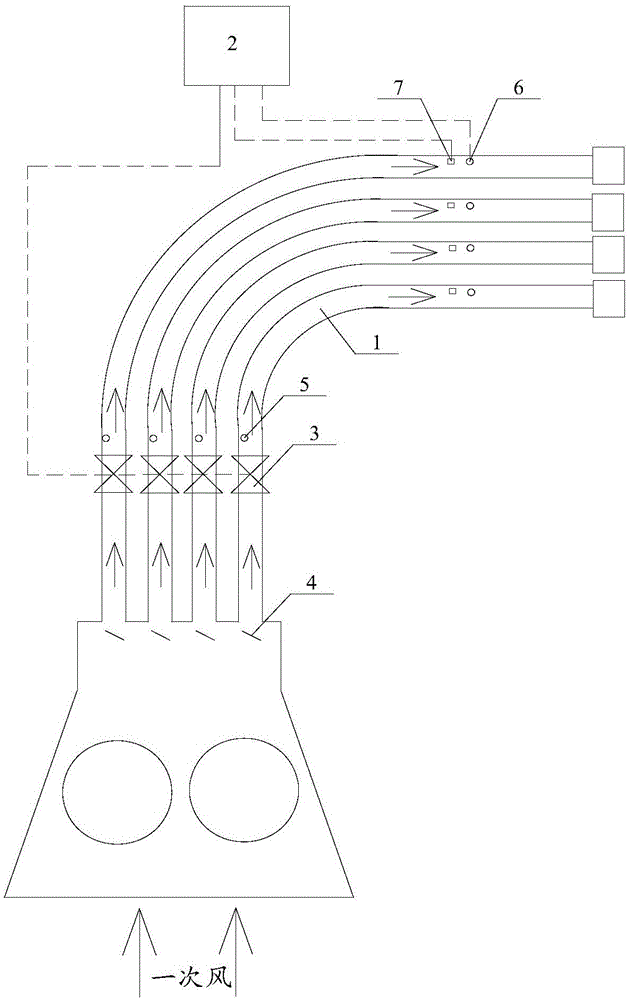

[0028] Such as figure 1 As shown, wherein, the flow rate monitoring unit monitors the coal powder flow rate in each pulverized coal delivery pipe 1 in real time; the concentration monitoring unit monitors the coal powder concentration in each pulverized coal delivery pipe 1 in real time; the adjustment processing unit 2 according to each pulverized coal The pulverized coal flow rate and pulverized coal concentration of the conveying pipe 1 are obtained to obtain the pulverized coal mass flow rate of each pulverized coal conveying pipe, and output corresponding control signals to adjust the opening degree and The angle of the pulverized coal concentration adjustment plate set in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com