An engine control system and control method matching two engines and one propeller

A control method and a technology of a control system, which are applied to the engine control system and control field matching two engines and one propeller, can solve the problems of system complexity, small layout space, and high cost, and achieve the goal of improving economy, small layout space, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

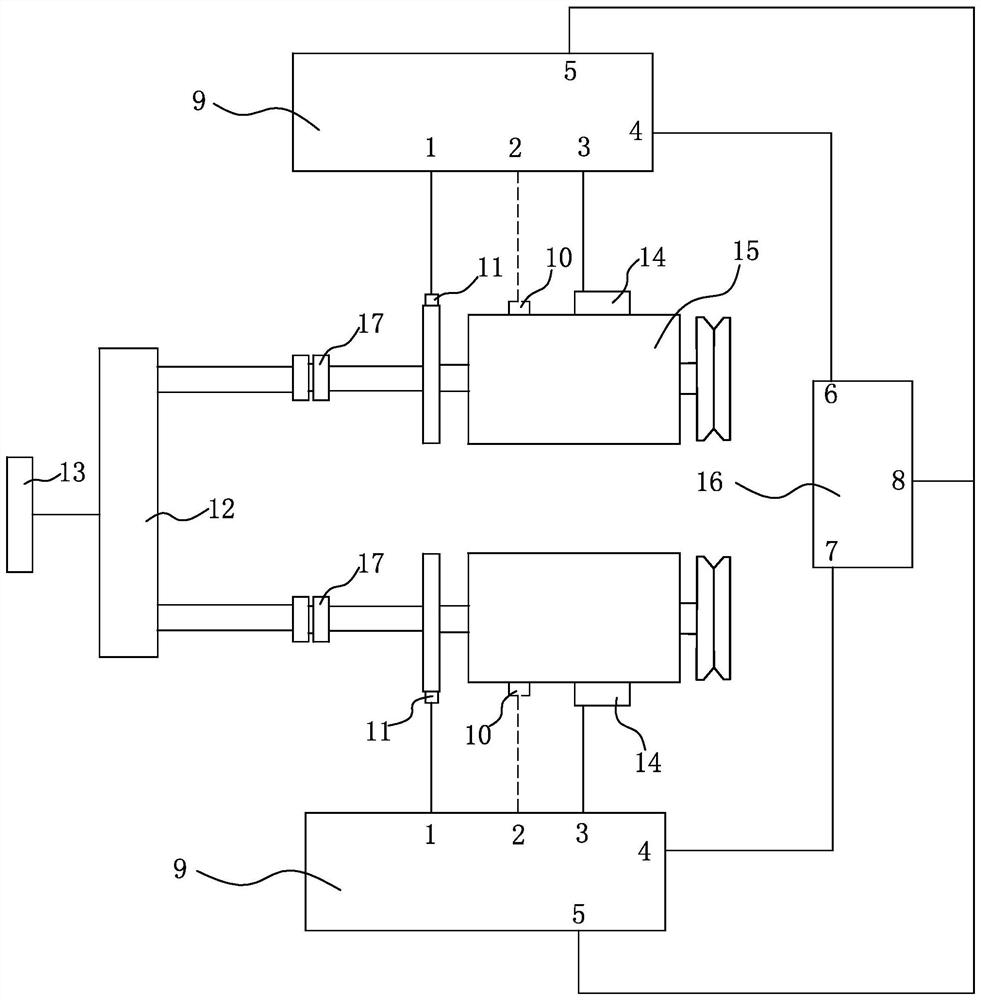

[0035] Such as figure 1 As shown, a kind of engine control system that matches twin-engine and single-propeller includes two engines 15 of the same model configuration (engines of the same model configuration work in the same environment, when the speed is consistent and the fuel consumption is close to the same working condition, Its output power is also close to), gear box 12 and propeller 13; Two engines 15 are connected the input end of gear box 12 by clutch 17 respectively, and the output end of gear box 12 is connected screw 13; Engine 15 and corresponding engine electronic control unit 9 electric Connected, the engine 15 is installed with a rotational speed sensor 11 and a fuel feeding unit 14 . The components described above and the connections between the components are all prior art, and will not be described in detail here.

[0036] In addition, the control system of this embodiment also includes a remote control unit 16; the remote control unit 16 is used to outpu...

Embodiment 2

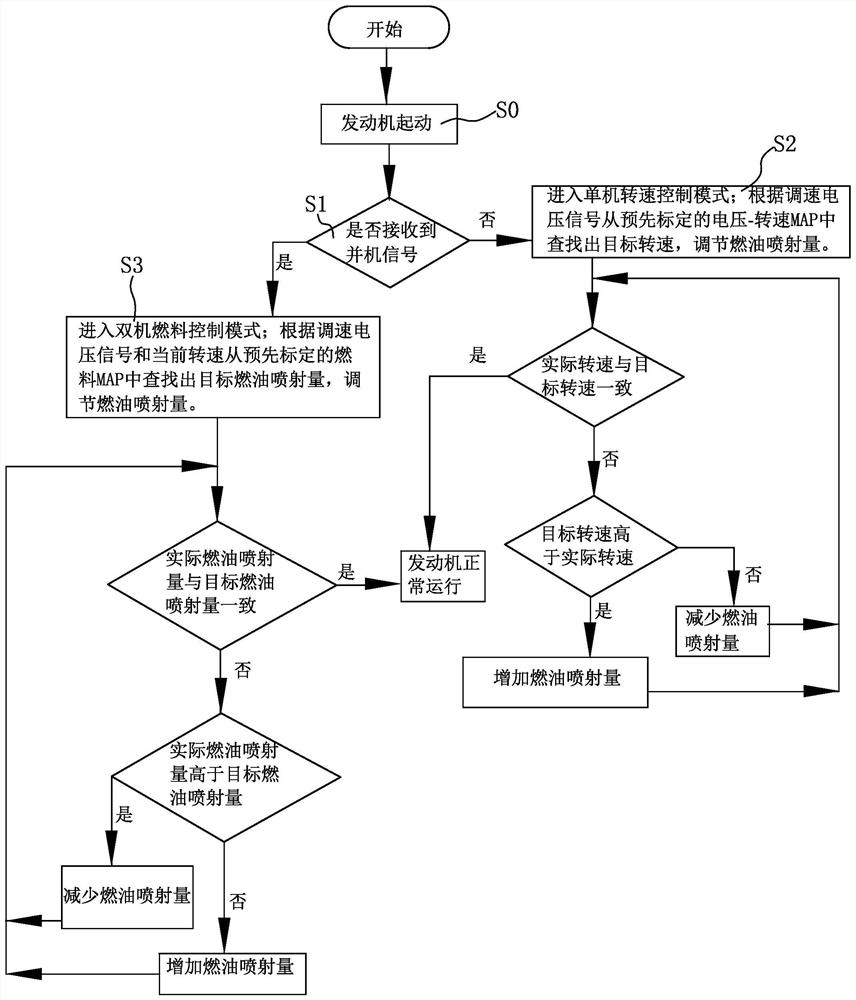

[0041] This embodiment is an engine control method based on the control system of Embodiment 1 matching twin engines and single propellers; the engine in this embodiment is a diesel engine, and the fuel in this embodiment refers to fuel oil. Depend on figure 1 and figure 2 As shown collectively, the control method includes the following steps:

[0042] S0, the engine 15 is started, and the remote control unit 16 is operated.

[0043] S1, whether the engine electronic control unit 9 receives the parallel signal output by the remote control unit 16, if not, execute step S2; if so, execute step S3;

[0044] S2, the engine 15 (remote control unit 16 outputs the speed regulation voltage signal to one of the motors 15) that receives the speed regulation voltage signal enters the stand-alone speed control mode; find out the target speed from the pre-calibrated voltage-speed MAP according to the speed regulation voltage signal , to adjust the fuel injection amount (by using PID co...

Embodiment 3

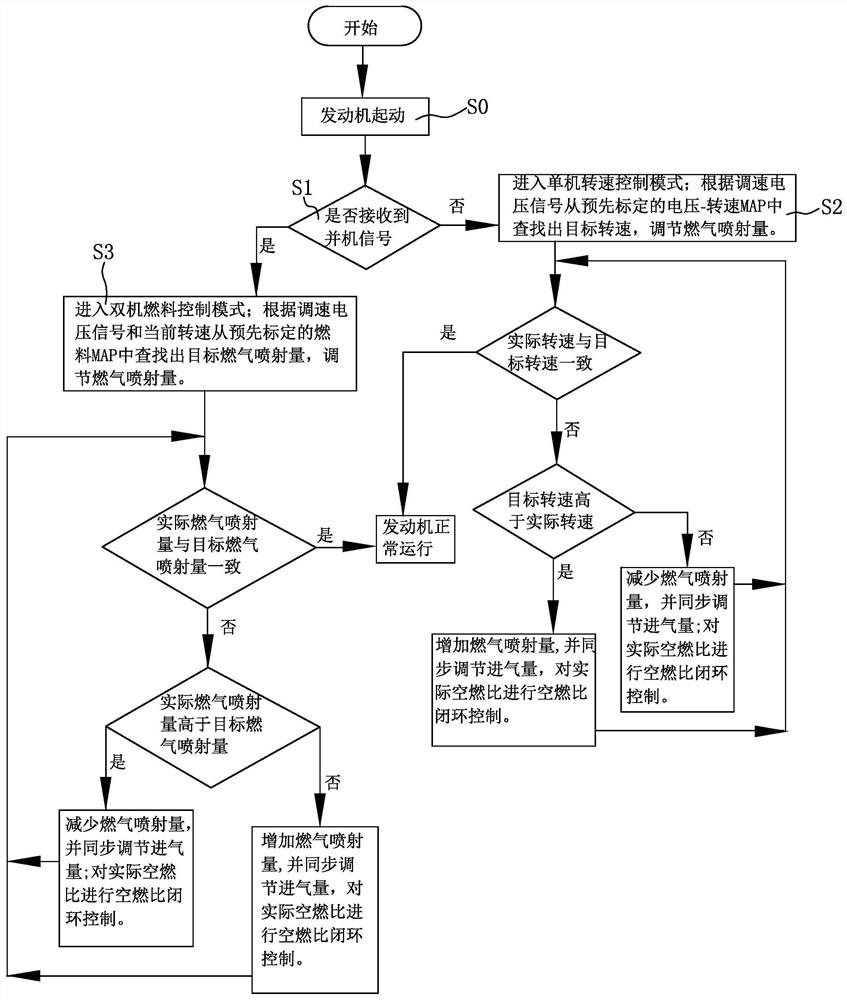

[0052] This embodiment is another engine control method based on the control system of Embodiment 1 to match two engines and one propeller; the engine in this embodiment is a gas engine; the fuel in this embodiment refers to gas, which is determined by figure 1 and image 3 As shown collectively, the control method includes the following steps:

[0053] S0, the engine 15 is started, and the remote control unit 16 is controlled.

[0054] S1. Whether the engine electronic control unit 9 receives the parallel signal output by the remote control unit 16, if not, execute step S2; if yes, execute step S3.

[0055] S2, the engine 15 that receives the speed regulation voltage signal now enters the stand-alone speed control mode; the engine electronic control unit 9 finds out the target speed from the pre-calibrated voltage-speed MAP according to the speed regulation voltage signal, and adjusts the gas injection amount (using PID The control is gradually adjusted, and the executive c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com