High and low torque pressure switch tester

A pressure switch and tester technology, applied in circuit breaker testing and other directions, to achieve the effects of simple external connection, flight protection, and reduced failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

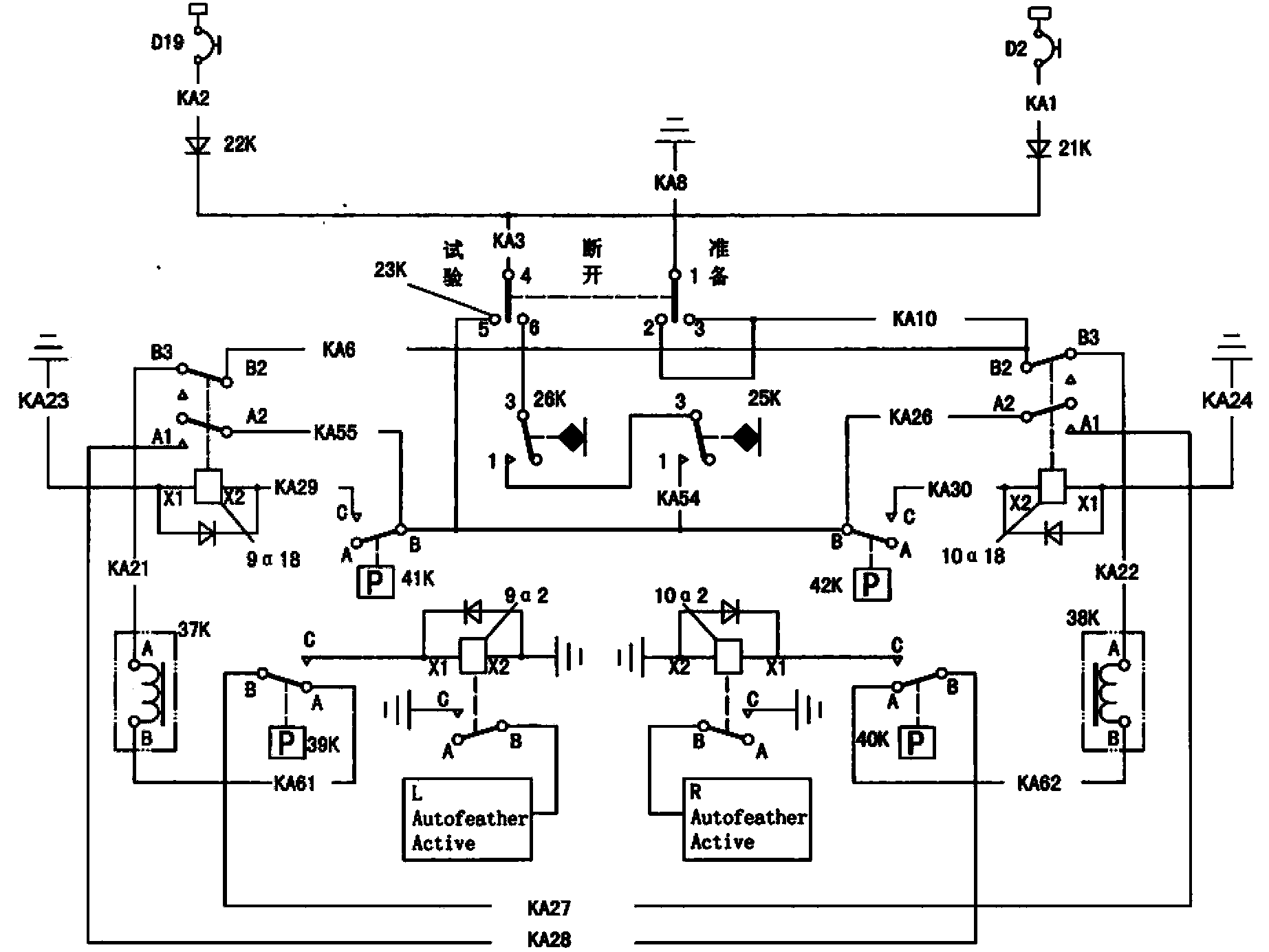

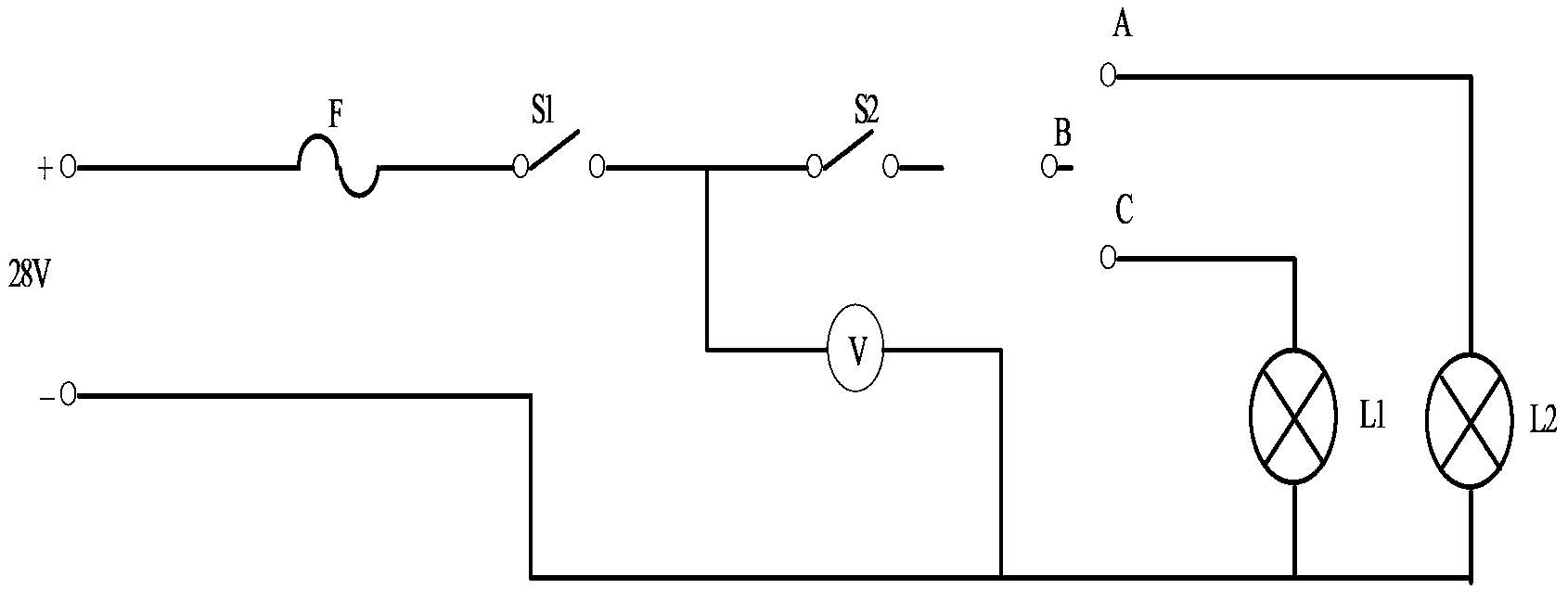

[0020] Below in conjunction with accompanying drawing, the utility model is described in detail. The selection of components in the overall design process of the present invention conforms to the GJB546-1996 component quality assurance specification.

[0021] High and low torque pressure switch tester, the switch tester includes SPDT switches S1, S2, indicator lights L1, L2, fuse F and a voltmeter; among them, the DC power supply is connected to the SPDT switch S1 through the fuse F, and the SPDT One end of the switch S1 is connected to the SPDT switch S2, the other end of the SPDT switch S1 is connected to the voltmeter, one end of the SPDT switch S2 is connected to the indicator light L1, the other end of the SPDT switch S2 is connected to the indicator light L2, and the voltmeter , Indicator light L1 and indicator light L2 are connected to the negative terminal of the power supply.

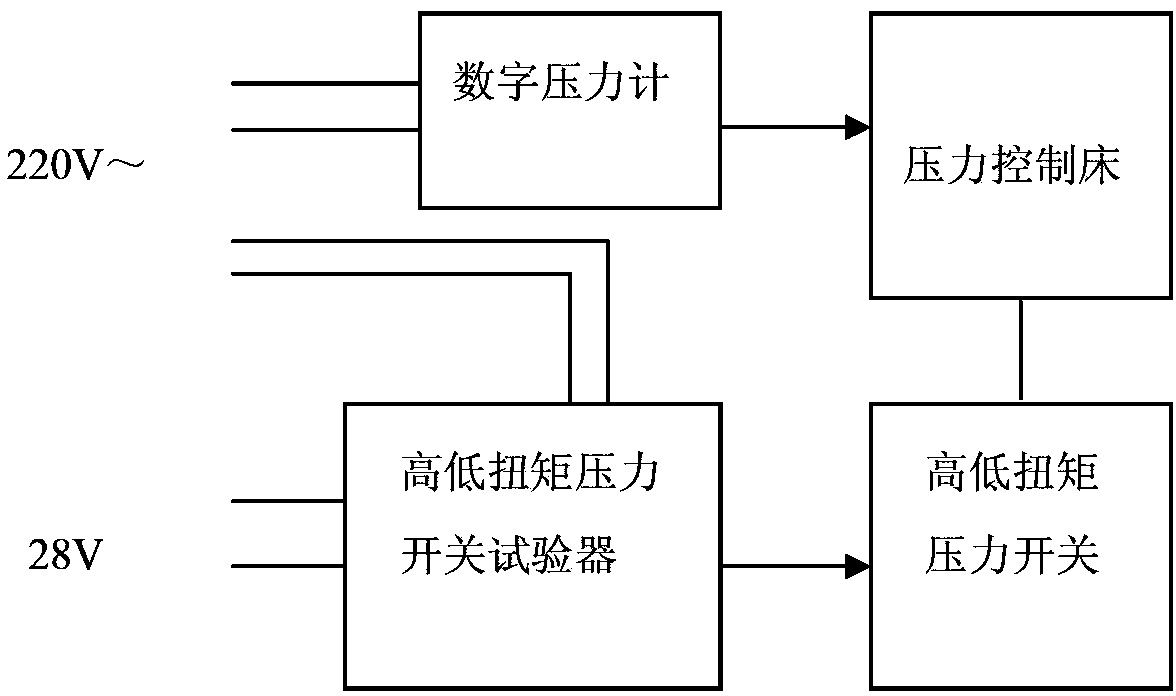

[0022] During the test, connect the digital pressure gauge to the 220V AC power supply, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com