Steel sheet having hot-dip galvanized layer and exhibiting superior plating wettability and plating adhesion, and production method thereof

A hot-dip galvanized steel sheet, hot-dip galvanized technology, applied in hot-dip galvanizing process, manufacturing tools, chemical instruments and methods, etc. Excellent effect of excellent plating wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0112] Hereinafter, the present invention will be specifically described by way of examples.

[0113] As mentioned above, the usual casting, hot rolling, pickling, and cold rolling are carried out by the continuous hot dip galvanizing equipment equipped with a full radiant tube heating furnace, which is a relatively high-productivity heating method that is less likely to cause sticking. Samples 1 to 72 of the 1 mm-thick cold-rolled sheet shown in Table 1 were annealed and plated. By using the full radiant tube type, as mentioned above, roll sticking is less likely to occur, and productivity is also good.

[0114] Table 1-1

[0115] Table 1 Composition and thickness of cold-rolled steel sheets

[0116]

[0117] Table 1-2

[0118]

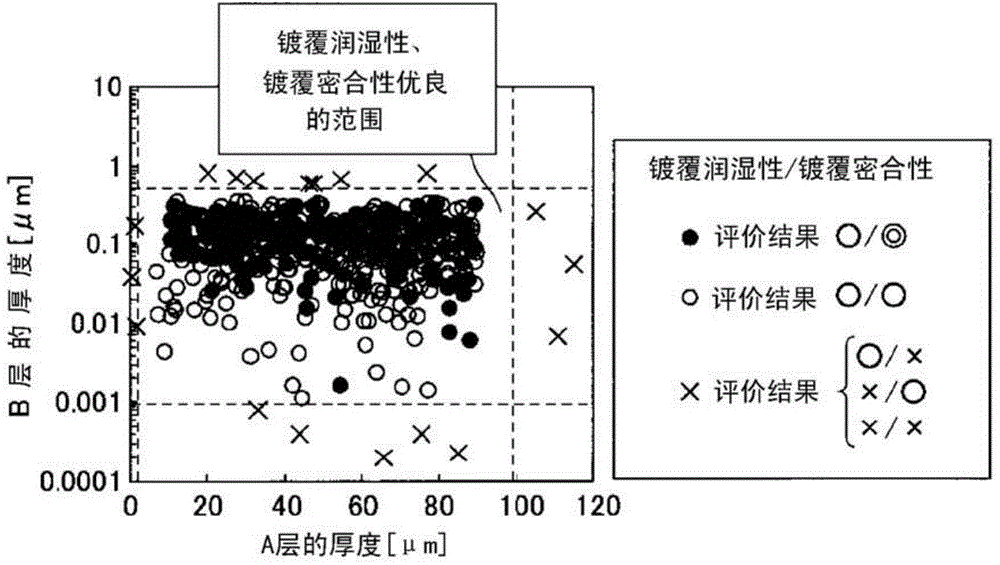

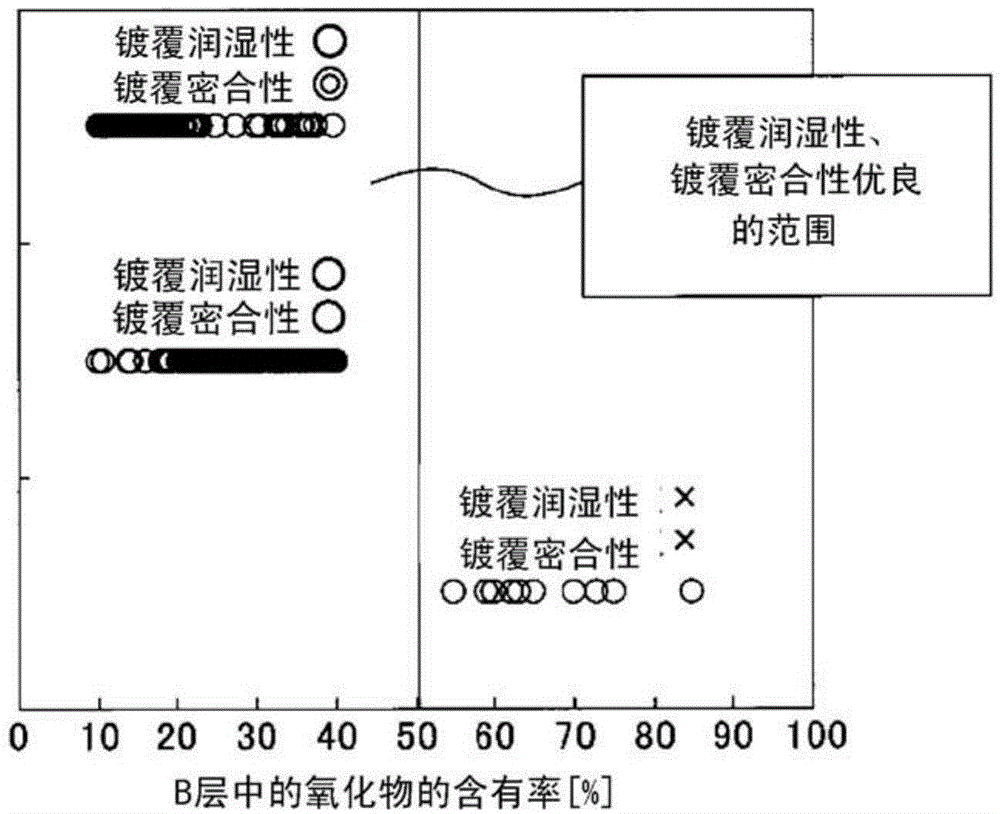

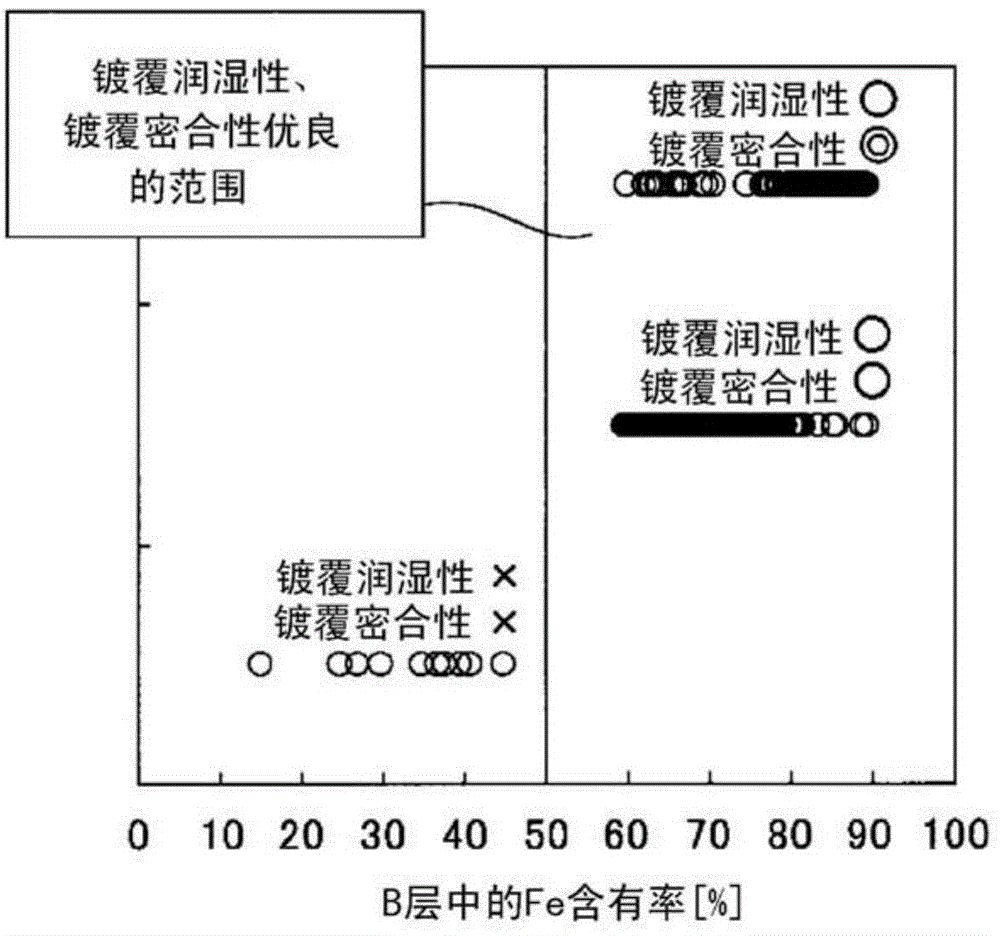

[0119] Nitrogen gas containing hydrogen and water vapor was introduced into the heating furnace and the soaking furnace, respectively. Tables 2 to 7 show the conditions in the heating furnace and the soaking furnace, and the logarithm log(P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com