Full-automatic gasket assembler

An assembly machine, fully automatic technology, applied in metal processing, metal processing equipment, manufacturing tools and other directions, can solve the problems of inaccurate installation position, reduce production efficiency, affect product quality and other problems, achieve a wide range of applications, prevent damage to products, The effect of saving time and space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

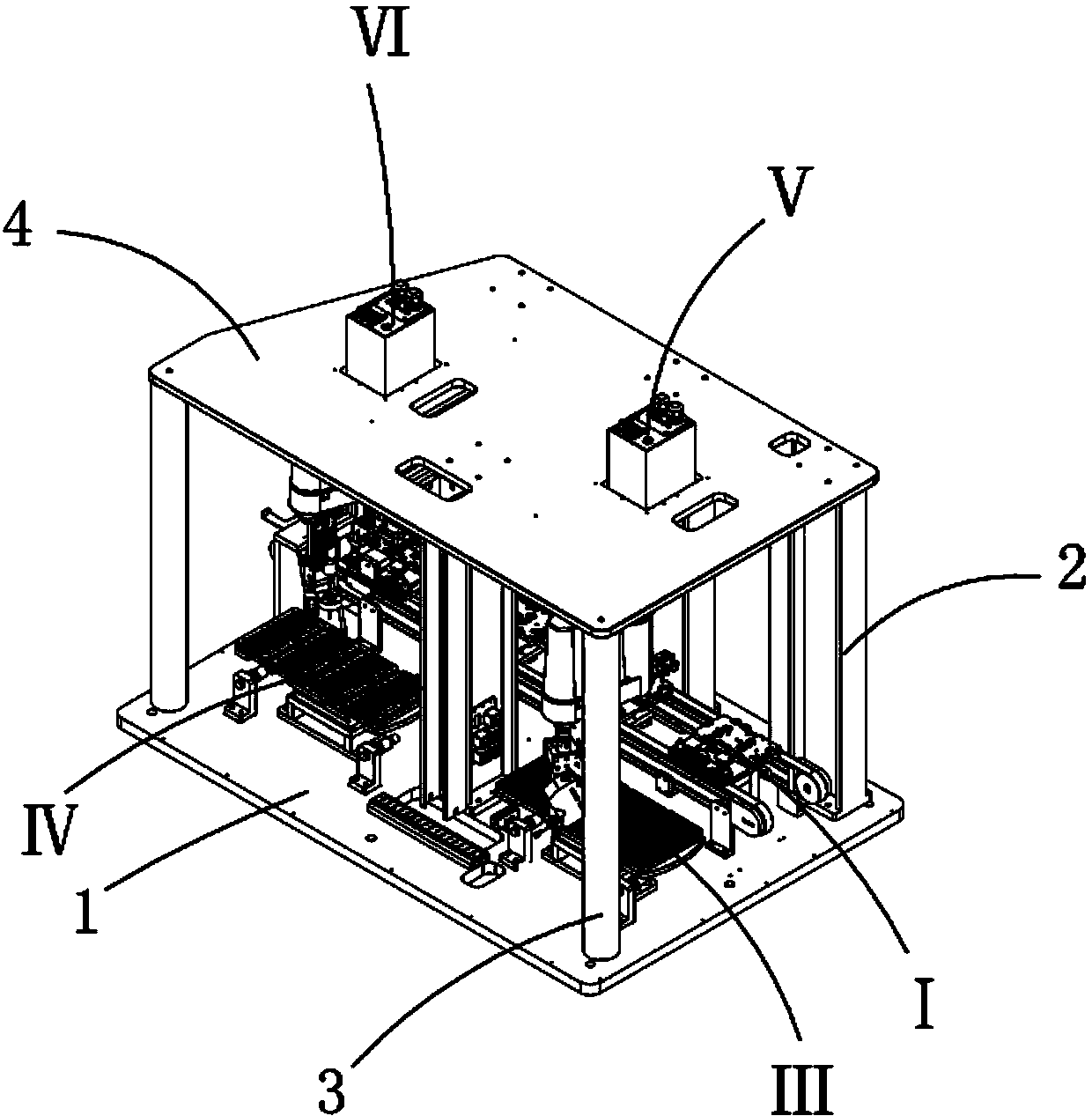

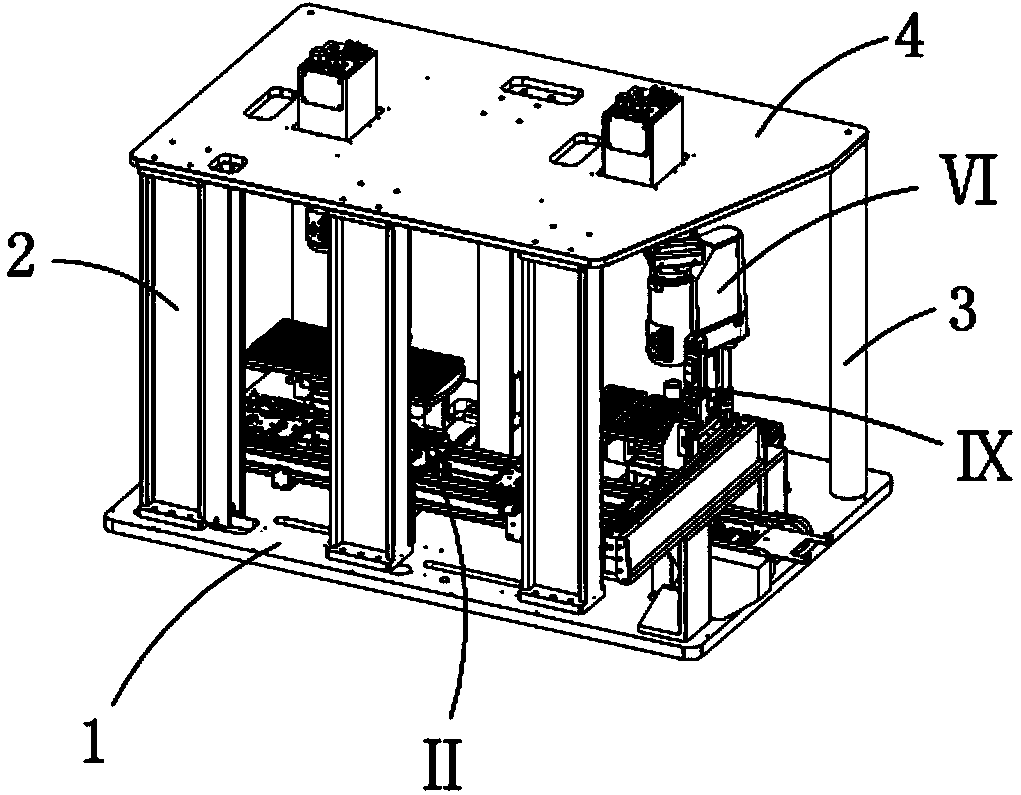

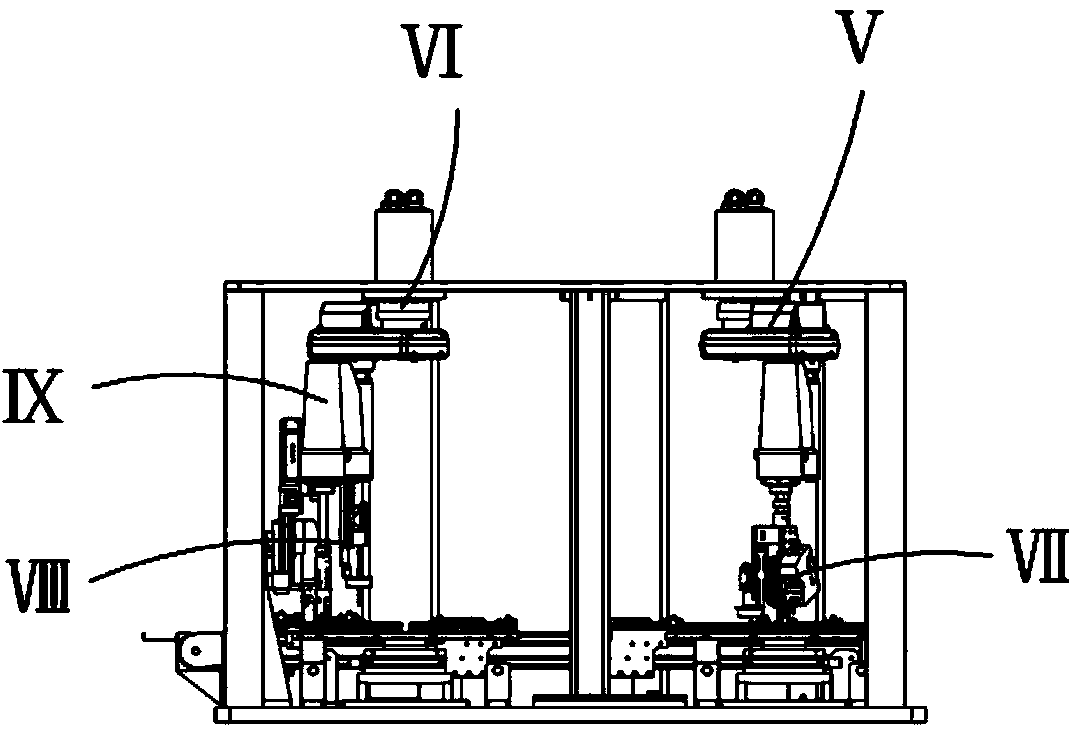

[0046] example, see attached Figures 1 to 15 , a fully automatic gasket assembly machine, which includes a bottom plate 1, a column 2, a support column 3, a top plate 4, an assembly line mechanism I, a product carrier II, a tray mechanism aIII, a tray mechanism bIV, a manipulator aⅤ, a manipulator bVI, The gasket suction mechanism aⅦ, the gasket suction mechanism bⅧ and the carrier transport mechanism IX, the bottom plate is connected to the top plate through the upright column and the support column; the assembly line mechanism, the tray mechanism a and the tray mechanism b are respectively installed on the bottom plate The manipulator a and the manipulator b are respectively installed on the top plate, the lower end of the manipulator a is connected to the gasket suction mechanism a, and the lower end of the manipulator b is connected to the gasket suction mechanism b; the gasket suction mechanism a can be driven by the manipulator a. The gaskets on the tray mechanism a are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com