Rubbish can system with single cylinder capable of achieving uniform compression

A technology of uniform compression and waste bins, applied in the direction of garbage storage, transportation and packaging, which can solve the problems of concentrated force, insufficient compression of garbage, and garbage storage space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

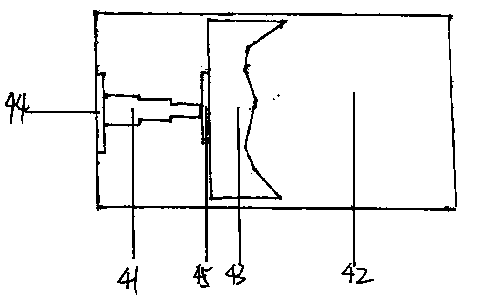

[0014] A single-cylinder uniformly compressed garbage box system includes a compression oil cylinder, a compression head, a garbage storage box, a box body connecting plate, and a compression head connecting plate. The compression head connecting plate on the compression head is connected to push the compression head to reciprocate. Implement the job of compressing garbage. Among them, the connection between the bolt and the box connecting plate is preferably connected by welding. The pin shaft and the connecting plate of the compression head are preferably connected in a movable manner, and the connecting plate of the compression head is preferably a hemisphere. For the sake of simplicity and convenience in design, the compression head is set to a W shape, and of course, the shape of the compression head may also be a zigzag shape or a wavy shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com