A horizontal electroplating tank device that realizes uniform distribution of metal strip coating thickness

A coating thickness and uniform distribution technology, applied in the field of metal strip electroplating process equipment, can solve the problems of uneven lateral distribution of coating thickness, quality defects, etc., and achieve the effect of uniform distribution and good coating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

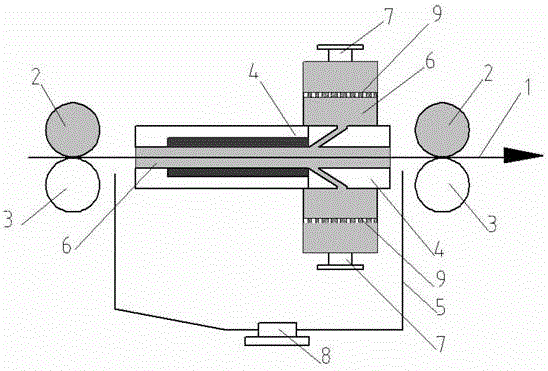

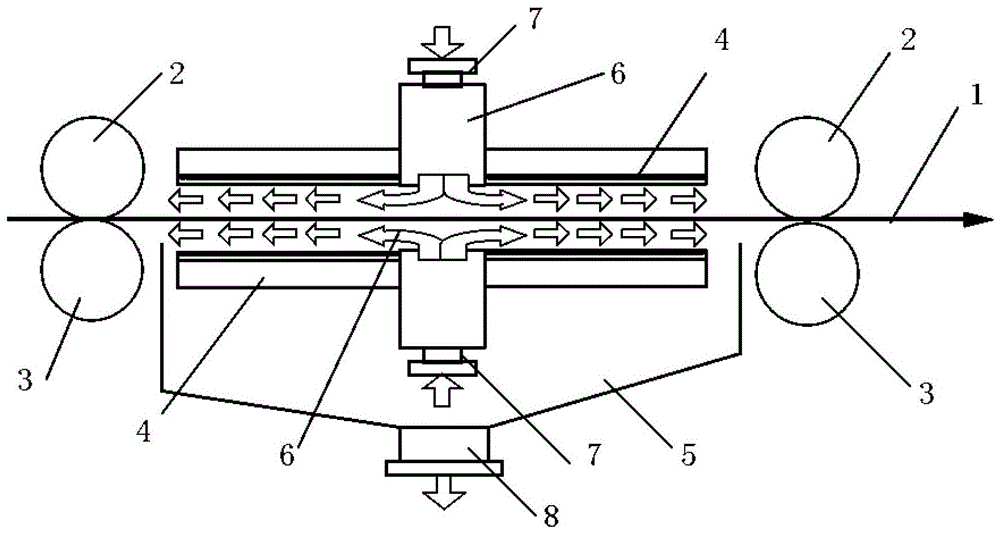

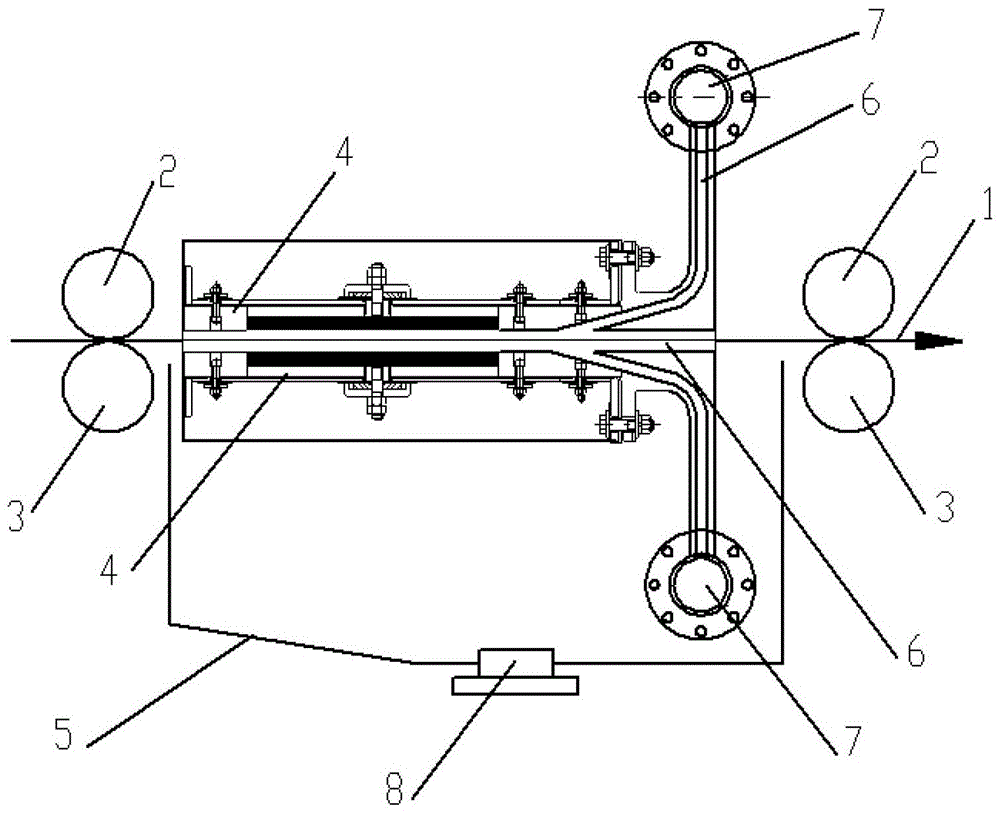

[0024] Horizontal electroplating tank of the present invention such as image 3 shown. The metal strip 1 passes through the plating tank device, and there are a pair of rollers in the front and back of the plating tank, the upper roller is the conductive roller 2, and the lower roller is the backup roller 3. Anode plate components 4 are arranged on the upper and lower surfaces of the metal strip, and the outside of the electroplating area is a tank body 5 for collecting the backflow of the electroplating solution. The electroplating solution 6 enters the upper and lower electroplating areas from the middle liquid inlet pipe 7 of the electroplating tank, and flows back into the circulation system outside the plating tank through the liquid outlet pipe 8 . The frame where the upper and lower anodes are installed in the anode plate assembly 4 is designed to have a buffer cavity structure. A buffer cavity structure is provided at the inlet of the electroplating solution. Before ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com