Flow guiding platform conical valve for retarder

A cone valve and platform technology, applied in the direction of balance valve, lifting valve, valve details, etc., can solve the problems of large impact force, off-line, and dangerous shunting operation, and achieve small pressure overshoot, convenient processing, and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

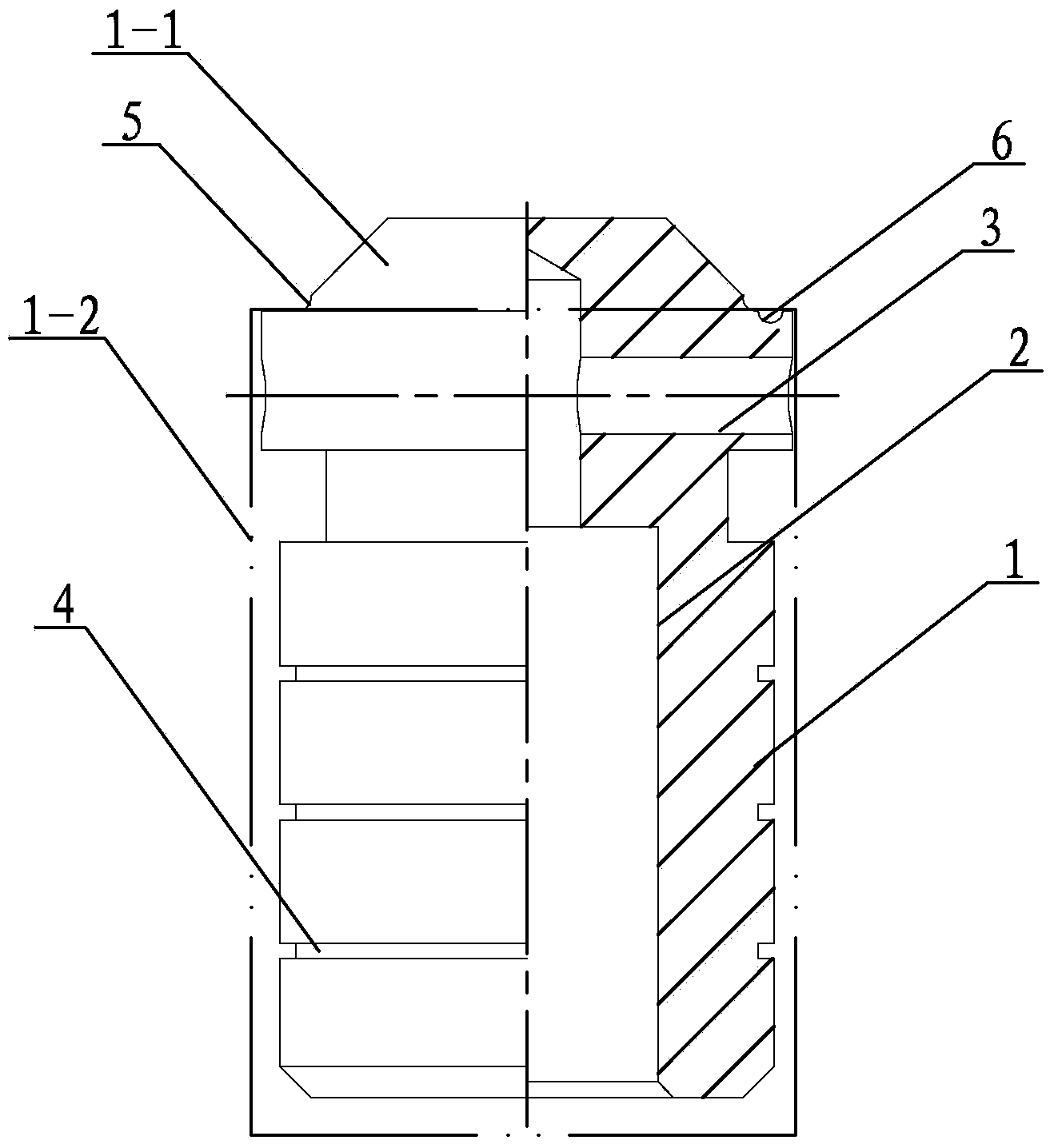

[0013] Specific implementation mode one: combine figure 1 Describe this embodiment, a conical valve of a diversion platform for a deceleration roof in this embodiment includes a valve body 1, and the valve body 1 includes a cone 1-1 and a diversion platform 1-2, and the diversion platform 1-2 It is a columnar platform, the cone 1-1 and the diversion platform 1-2 are fixedly arranged from top to bottom, the diversion platform 1-2 is provided with a stepped inner cavity 2, and the through hole 3 is pierced through the diversion platform 1 -2, and the through hole 3 is perpendicular to the diversion platform 1-2, and the bottom of the diversion platform 1-2 is provided with a plurality of grooves 4 from top to bottom along its outer wall, and the cone 1-1 The cone 1-1 at the intersection with the diversion platform 1-2 is provided with a cone pressure relief arc groove 5, and the diversion platform at the intersection of the cone 1-1 and the diversion platform 1-2 1-2 is provide...

specific Embodiment approach 2

[0014] Specific implementation mode two: combination figure 1 Describe this embodiment, the quantity of a plurality of grooves 4 of this embodiment is 4, and the width of described 4 grooves 4 is not equal, and the width of the first groove 4 counting from top to bottom is 3mm, and the remaining 3 Each groove 4 width is 0.5mm. Such a setting facilitates satisfying the diversion function. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0015] Specific implementation mode three: combination figure 1 To describe this embodiment, the arc radii of the cone pressure relief arc groove 5 and the platform pressure relief arc groove 6 in this embodiment are both 0.4 mm. Such setting can effectively reduce the impact of the hydraulic flow on the cone valve. Other compositions and connections are the same as those in the second embodiment.

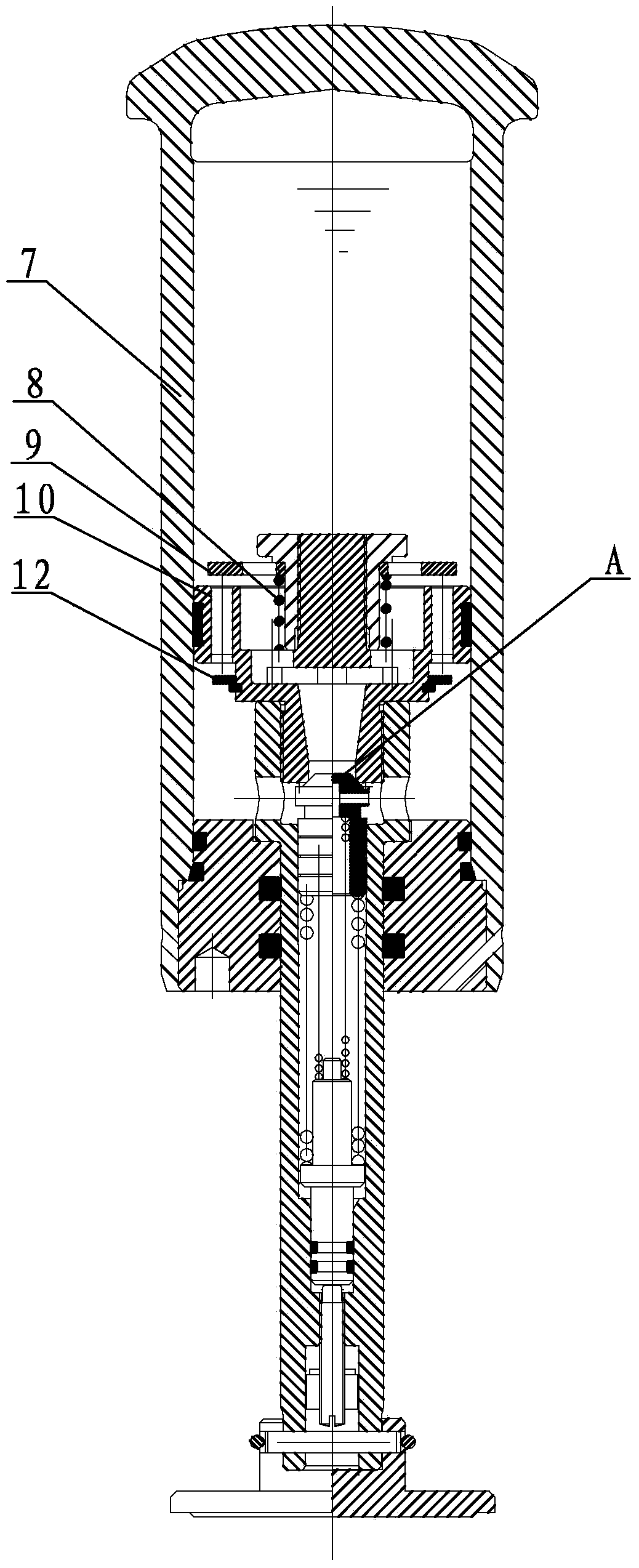

[0016] combine figure 2 Explain that the working principle of applying the diversion platform cone valve of the present invention to the high-load deceleration roof is as follows: (assuming that the diversion platform cone valve of the present invention is in the figure 2 Indicated as A)

[0017] When the speed is lower than the critical speed: When the rolling speed of the vehicle is lower than the critical speed set by the high-load deceleration top, the speed at which the sliding cylinder 7 is pressed down by the wheel is relatively low, and the flow generated by the oil in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com