One-time molding tray tooling with LED light strips of any cross-sectional shape surrounding the glue

A technology of LED strips and cross-sections, applied to electrical components, circuits, semiconductor devices, etc., can solve problems such as complex production process, product defects and hidden quality problems, difficulty in large-scale and high-efficiency production, and achieve optimized manufacturing process, High-efficiency batch production and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred embodiments of the present invention are described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

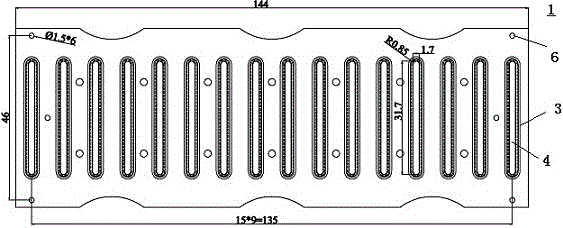

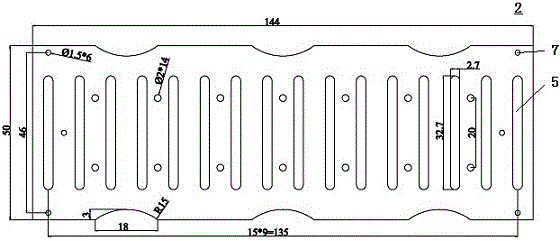

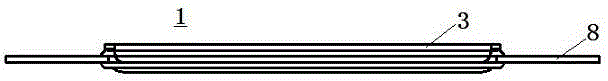

[0023] See attached figure 1 to attach Figure 5 As shown, the LED light bar with any cross-sectional shape described in this embodiment surrounds the glue-filled one-time forming tray tooling, which includes a molded bar tray 1 and a tray cover plate 2, and the overall size of the two matches. The upper surface of the molding tray 1 is provided with a plurality of positioning areas 3 for placing LED light strips. The positioning area 3 has a concave plastic molding surface 4 for silicone colloid molding. The expansion coefficient of the plastic molding surface 4 and the silicone colloid is the same. Therefore, in the subsequent drying process, since the silicone colloid and the plastic molding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com