Upper parts for fittings

A technology of parts and accessories, which is applied in the field of valve parts, can solve the problems of lip seal deformation and damage the sealing effect of lip seal, and achieve the effect of avoiding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

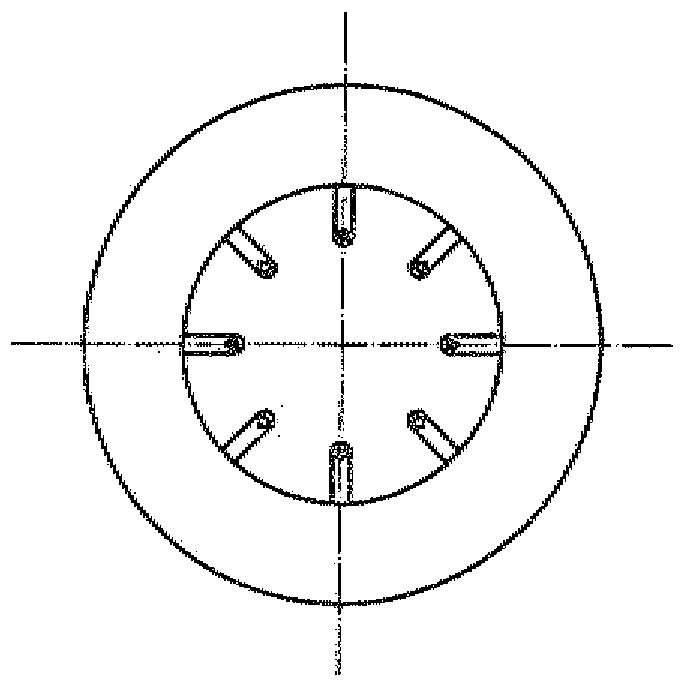

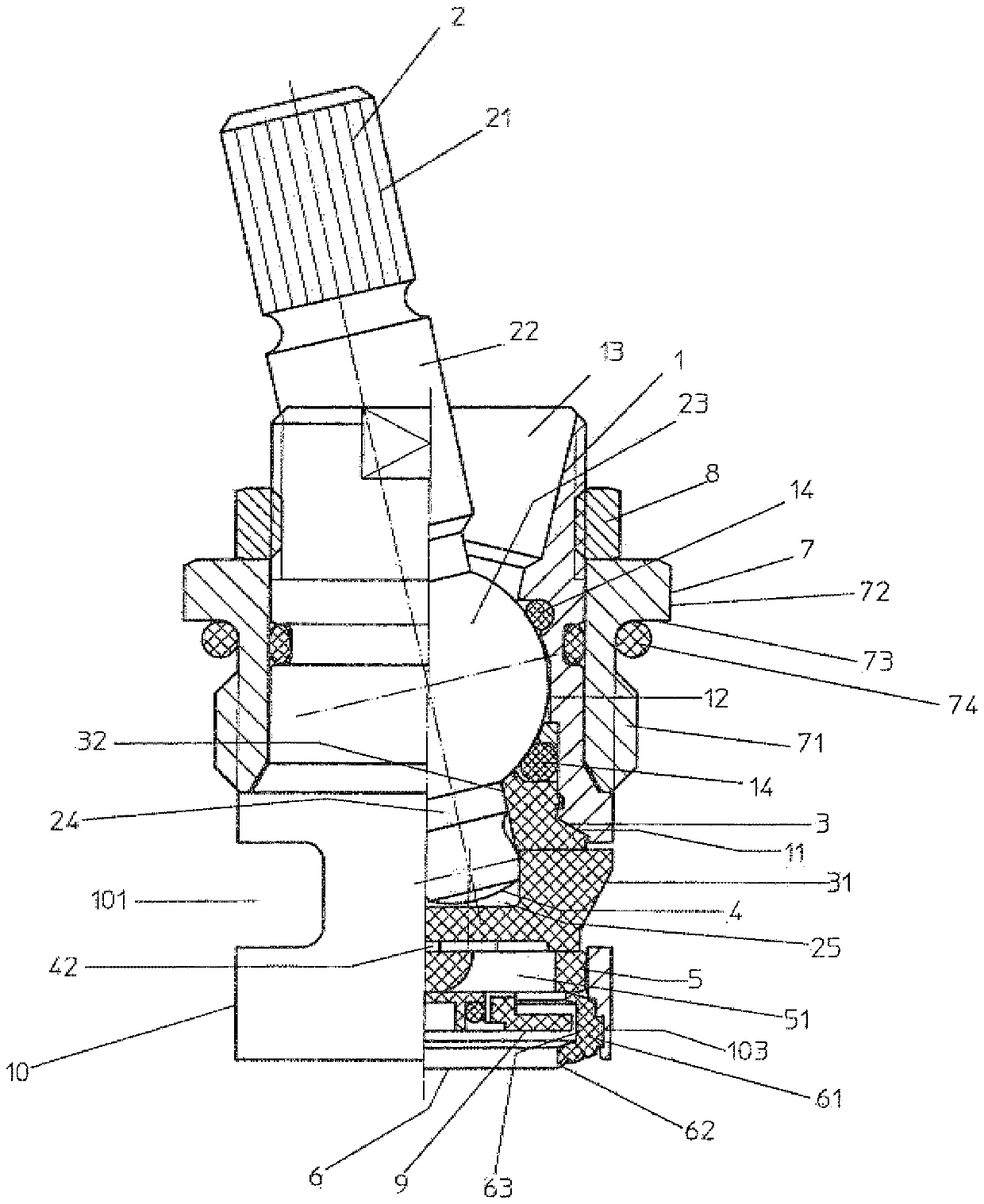

[0022] The valve top part chosen as the exemplary embodiment has a top part 1 through which a spindle 2 guided radially passes through. The spindle 2 is guided through a rotationally fixed disk guide 3 and is positively connected to a control disk 4 , which is in turn guided in the disk guide 3 . The control disk 4 is in contact with an inlet disk 5 which is held in the top part 1 and which is in contact on its side facing away from the control disk 4 with a seal 6 which accommodates a flow restrictor 9 . Arranged centrally around the top part 1 is a coupling sleeve 7 which is fastened on its side facing the seal 6 with a union nut 8 .

[0023] The top part 1 consists of a symmetrical hollow body which is open at both ends. The top part 1 has a sleeve-shaped part 10 on its side facing the fitting (not shown). The top part 1 has a central inlet at the free end of the sleeve-shaped part 10 . A passage window 101 is provided in the sleeve-shaped part 10 . In a development of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com