Layer plate carrier

A technology of long slabs and limit parts, which is applied in the field of support, can solve the problems of cumbersome installation and disassembly steps, affect the efficiency of assembly construction work, and affect the overall aesthetics of the wall, and achieve easy disassembly and assembly, which is conducive to mass production , the effect of ingenious structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

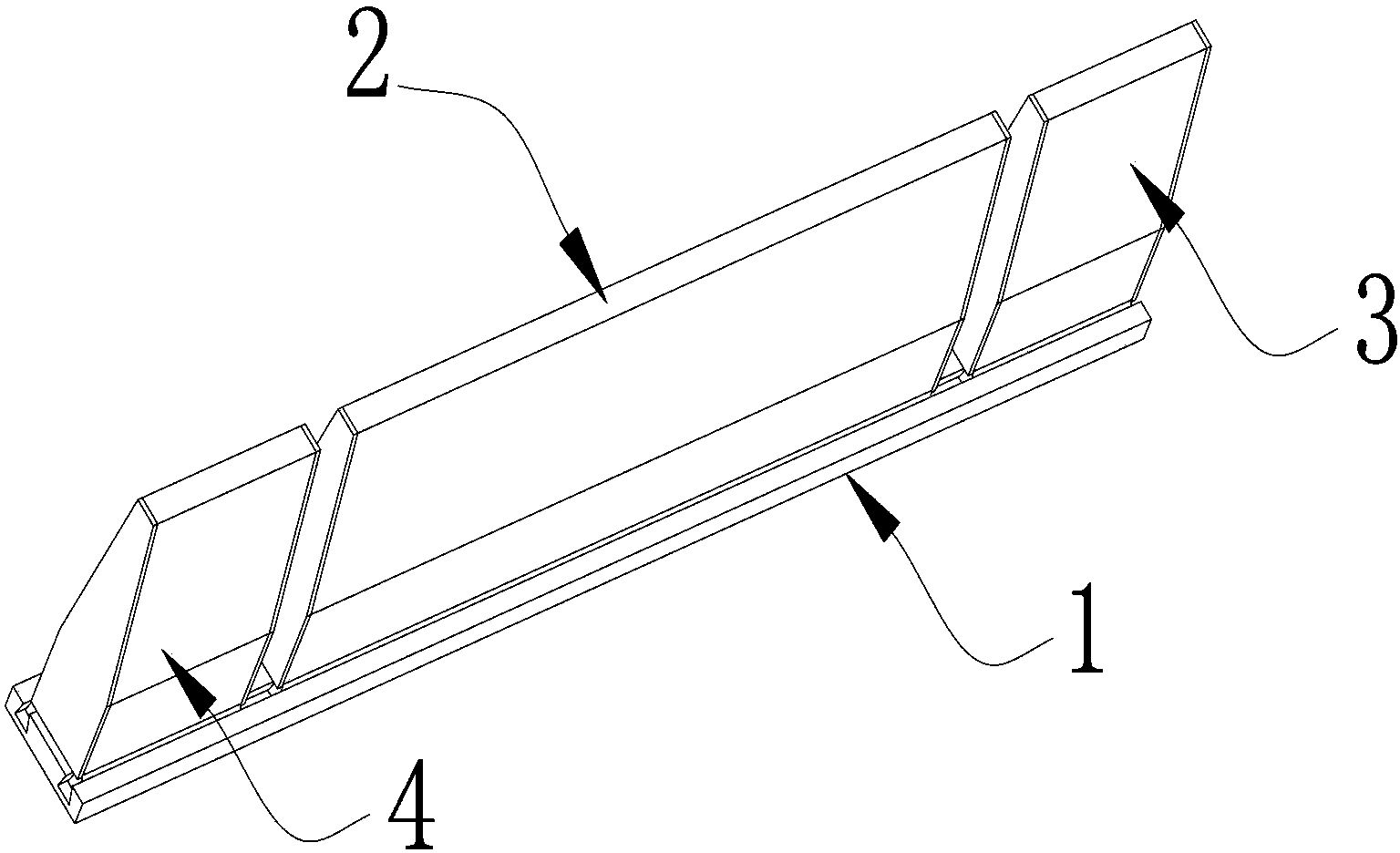

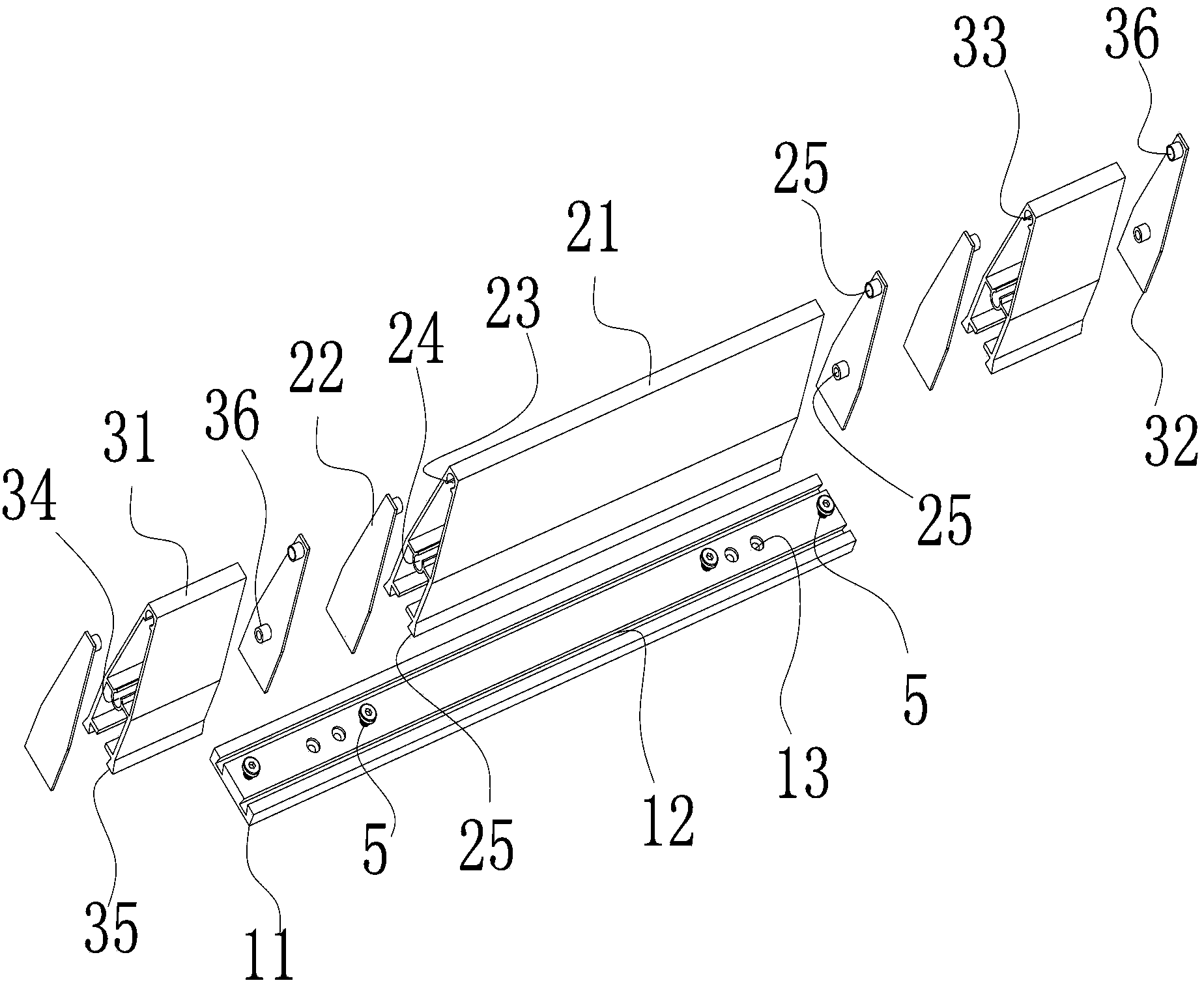

[0016] see figure 1 with figure 2 , a laminate bracket provided in this embodiment, which includes a seat body 1, which also includes a support portion 2, a limiting portion 3 and a limiting portion 4, the seat body 1 is a long strip body 11, The long board 11 is provided with a slide rail 12 running along its long side, and each of the supporting part 2 and the position limiting part 3 is positioned and fixed on the slide rail 11 of the long board 11 through its corresponding locking part 5 . On the rail 12, when the locking part 5 is released, the corresponding supporting parts and limiting parts 3, 4 can slide on the slide rail 12. The locking part 5 is a screw. In this embodiment, the limiting parts 3 and 4 are symmetrically located at both ends of the supporting part 2 and arranged at intervals. In other embodiments, the position-limiting parts 3 and 4 can be arranged at one end of the supporting part 2 in sequence and at intervals according to the needs of use. The ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap