Chopping knife

A rivet and thread technology, which is applied in the field of thread rivets, can solve the problems of difficult workpiece splitting, etc., and achieve the effects of increasing volume and weight, reducing product cost, and being convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

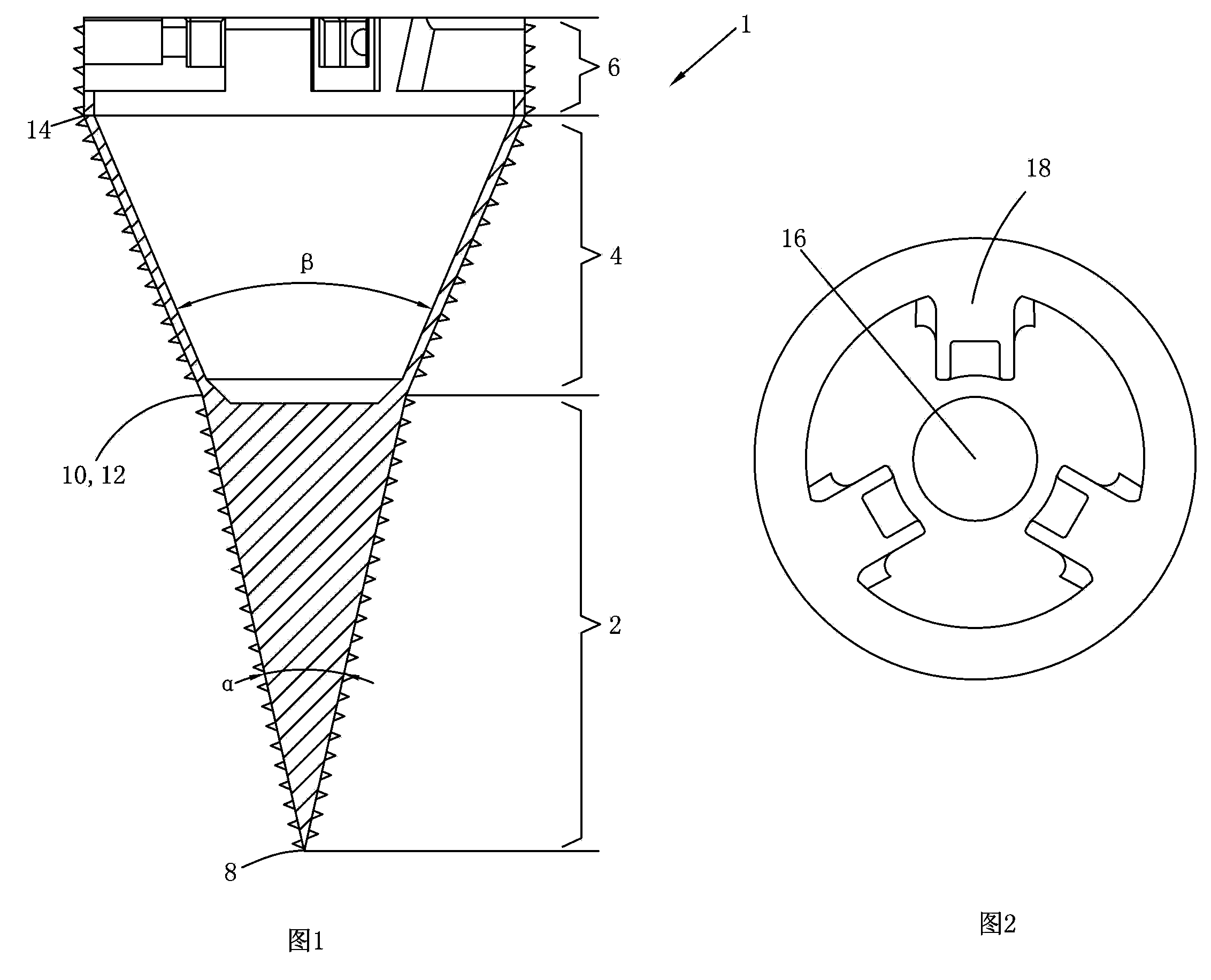

[0023] See figure 1 , The riving knife 1 of this embodiment is a threaded riving knife that rotates under the drive of a power source, and includes a threaded conical section 2, a threaded frustoconical section 4 and a threaded cylindrical section 6 connected in sequence.

[0024] The threaded conical section 2 has a head 8 and a tail 10 . Wherein, the head 8 is a cone point.

[0025] The smaller the taper angle α of the threaded cone section 2 is, the easier it is for the riving knife 1 to screw into the workpiece; but if the taper angle α of the threaded cone section 2 is too small, the strength of the threaded cone section may not be sufficient. In this embodiment, preferably, the taper angle of the threaded conical section 2 is greater than or equal to 15 degrees and less than or equal to 35 degrees. More preferably, the taper angle of the threaded conical section 2 is 25 degrees. With such arrangement, the threaded conical section 2 can be smoothly screwed into the wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com