Skirtboard lock and rail vehicle

A apron lock and lock shell technology, which is applied to railway car body, railway car body parts, railway transportation, etc., can solve the problems of falling out of parts of the apron lock, inconvenient disassembly process, and difficulty in dismantling, etc. The effect of easy observation, easy disassembly, and detachable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

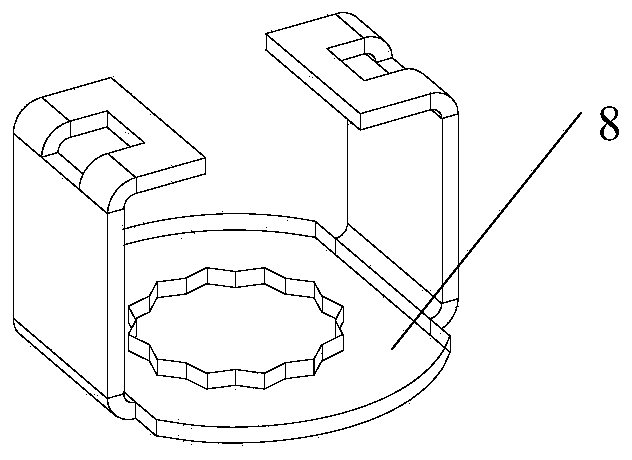

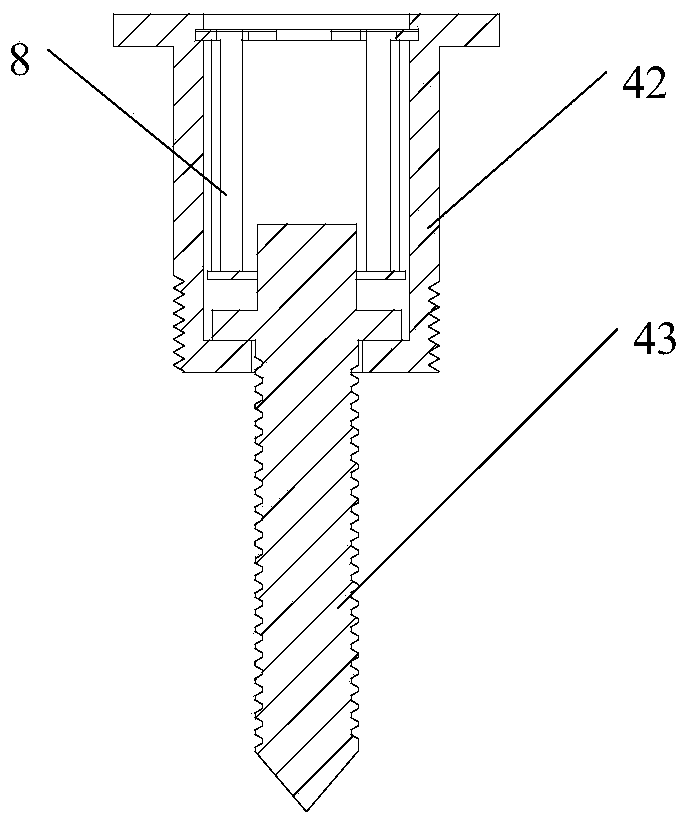

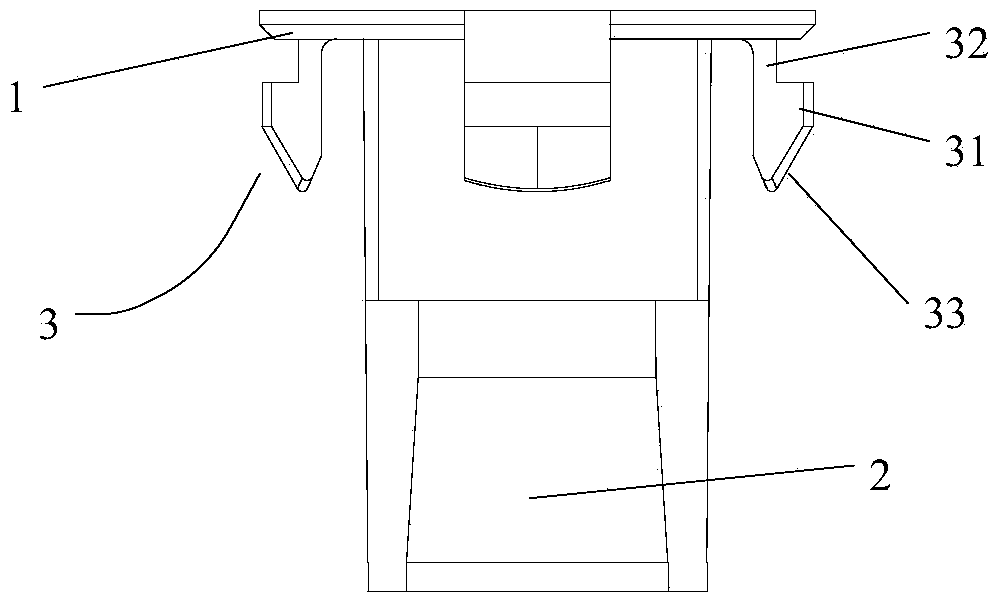

[0026] Figure 4 A front view showing an embodiment of a fastener for the present invention; Figure 5 A top view showing an embodiment of a fastener for the present invention; Image 6 It is an exploded view of an embodiment of the skirt plate lock of the present invention; Figure 7 It is a structural schematic diagram of an embodiment of the skirt board lock of the present invention. see Figure 4-Figure 7 An apron lock provided by an embodiment of the present invention includes a lock case 42 with a central hole and a locking screw 43 pierced through the lock case. The end of the locking screw 43 is a prism-shaped installation section 431 , and the installation section 431 and A gap is formed between the inner surfaces of the lock case 42; it also includes a display fastener arranged between the lock case 42 and the installation section 431; the bottom end of the display fastener has an installation hole 2 that matches the shape of the installation section 431, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com