Beam of dumping automobile

An automobile girder and self-unloading technology, which is applied to vehicle components, substructure, transportation and packaging, etc., can solve problems such as damage to components, hidden dangers of unsafe use of vehicles, and deviation of cargo compartment frame beams, etc., to achieve structural science Simple, solves the effect of poor safety and stability, and improves the overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

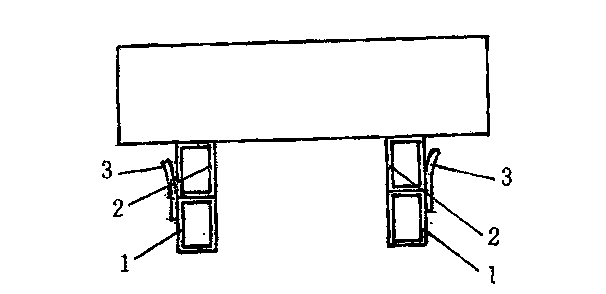

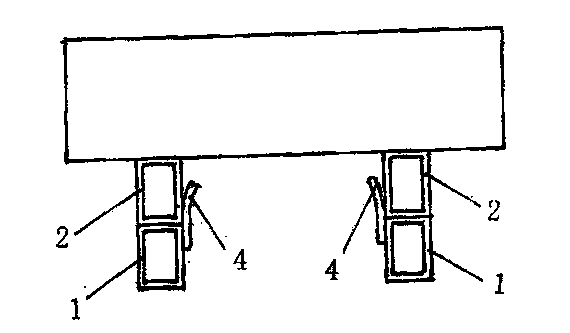

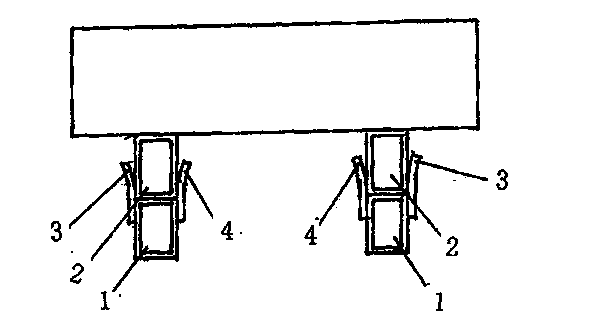

[0013] attached figure 1 , 2 Shown in , 3: the upper side of the car body girder 1 of the rotatable cargo box frame beam 2 of the dump truck is provided with a horn-shaped expansion wing.

[0014] figure 1 Middle: the set wing is that there is an outer expansion wing 3 on the upper and outer sides of the two car body girders 1 respectively.

[0015] figure 2 Middle: The set wing is that there is an inner expansion wing 4 on the upper inner side of the two car body girders 1.

[0016] image 3 Middle: the set wings are respectively provided with an outer expansion wing 3 and an inner expansion wing 4 on the inner and outer sides above the vehicle body girder 1 .

[0017] The car body girder 1 and the vehicle frame beam 2 involved in this technical solution are all square tube structures. During production, two channel steel butt joint welding members can be used, and two angle steel butt joint welding can also be used, especially if the square tube material is directly us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com