Preparation method of an ammonium nitrate aqueous solution

A technology of aqueous solution and ammonium nitrate, which is applied in the direction of ammonium nitrate, chemical instruments and methods, ammonia compounds, etc., can solve the problems of ammonium nitrate aqueous solution containing impurities, dangerous process, difficult to control, etc., so as to ensure the feasibility and safety , The state is safe and stable, and the effect is not easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

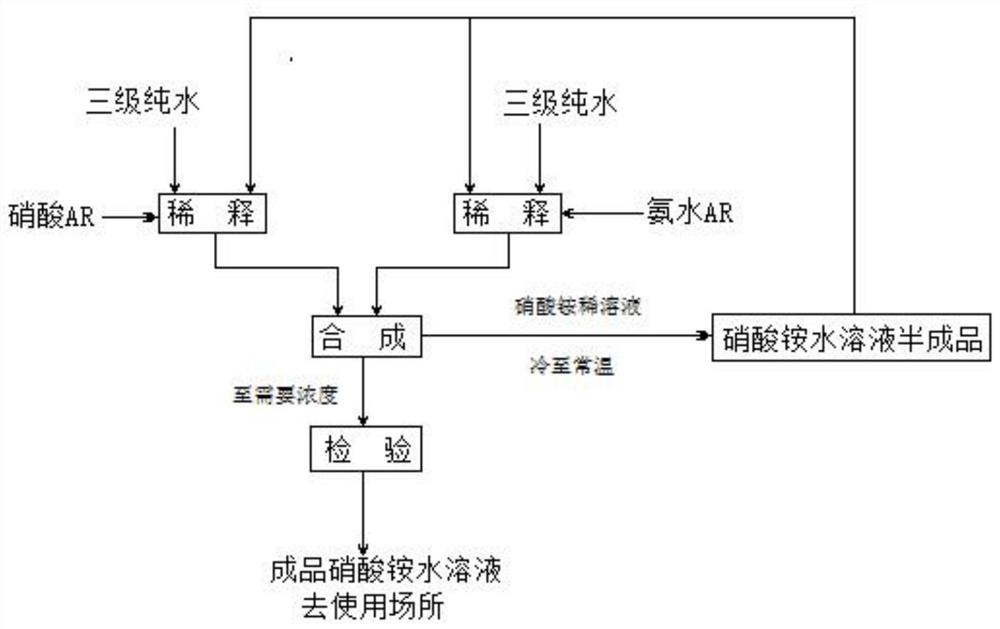

[0032] Specifically, a kind of ammonium nitrate aqueous solution preparation method comprises the following steps:

[0033] Step S01: Weighing 38.25 parts of ammonia water with a mass of 26.0% and a temperature of 20°C and adding it to 76.5 parts of pure water with a mass of 20°C to prepare the first diluted ammonia water;

[0034] Step S02: Weighing 54.51 parts of nitric acid with a mass of 65% and a temperature of 25°C and adding it to 109.02 parts of pure water with a mass of 20°C to prepare the first diluted nitric acid;

[0035] Step S03: Add the first diluted ammonia water obtained in step S01 to the first diluted nitric acid obtained in step S02 to obtain a first aqueous ammonium nitrate solution.

[0036] In this embodiment, the dilution temperature in the process of diluting ammonia water in step S01 remains unchanged at 20°C, and the dilution temperature in step S02 in the process of diluting nitric acid increases from 20°C to 30°C.

[0037] In this embodiment, the ...

Embodiment 2

[0041] Specifically, a kind of ammonium nitrate aqueous solution preparation method comprises the following steps:

[0042] Step S01: Weigh 62.21 parts of ammonia water with a mass of 26% and a temperature of 20°C and add it to 119 parts of a first ammonium nitrate aqueous solution with a mass of 5.25% and a temperature of 40°C to obtain a second diluted ammonia water ;

[0043] Step S02: Weigh 84.81 parts of nitric acid with a mass of 65% and a temperature of 25°C and add it to the first ammonium nitrate aqueous solution with a mass of 169.61 parts, a concentration of 5.25%, and a temperature of 40°C to obtain the second diluted nitric acid ;

[0044] Step S03: Add the second diluted ammonia water prepared in step S01 to the second diluted nitric acid prepared in step S02 to prepare a second ammonium nitrate aqueous solution.

[0045] In this embodiment, the dilution temperature in the process of diluting ammonia water in step S01 is reduced from 40°C to 32°C, and the dilut...

Embodiment 3

[0050] Specifically, a kind of ammonium nitrate aqueous solution preparation method comprises the following steps:

[0051] Step S01: Weigh 85 parts of ammonia water with a mass of 26% and a temperature of 20°C and add it to 170 parts of a second ammonium nitrate aqueous solution with a mass of 19.63% and a temperature of 30°C to obtain a third diluted ammonia water ;

[0052] Step S02: Weigh 121 parts of nitric acid with a mass of 65% and a temperature of 25°C and add it to 242.3 parts of a second ammonium nitrate aqueous solution with a mass of 19.63% and a temperature of 30°C to obtain a third diluted nitric acid ;

[0053] Step S03: Add the third diluted ammonia water prepared in step S01 to the third diluted nitric acid prepared in step S02 to prepare a third aqueous ammonium nitrate solution.

[0054]In this embodiment, the dilution temperature in the process of diluting ammonia water in step S01 remains unchanged at 30°C, and the dilution temperature in step S02 in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com