Shuttle for dense storage and lifting method thereof

A technology of dense storage and shuttle vehicles, which is applied in the field of shuttle vehicles for logistics and storage-intensive shelf storage. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but not as a basis for any limitation of the present invention.

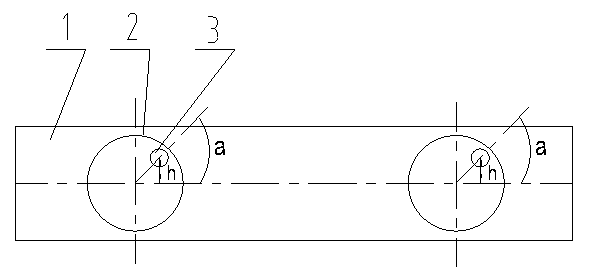

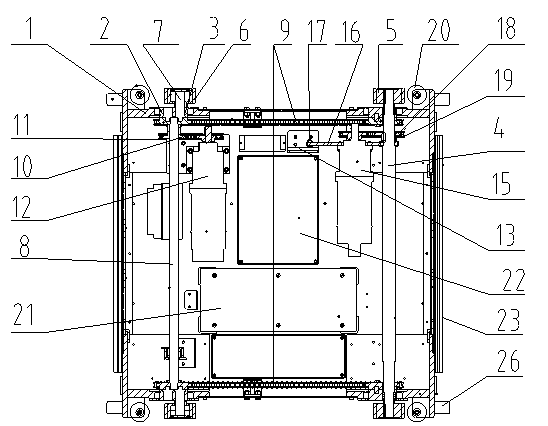

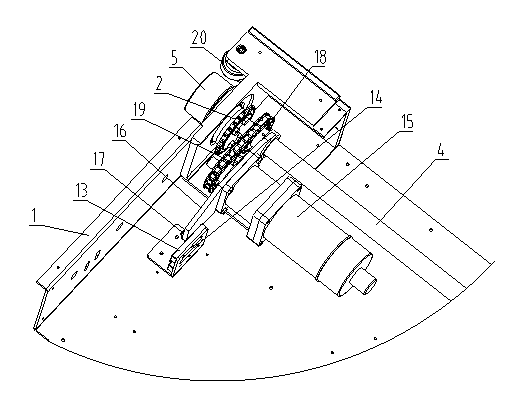

[0022] Embodiment of the present invention: when making the shuttle car for dense storage, the lifting method of the shuttle car for dense storage is implemented by a lifting method of the shuttle car for dense storage of the present invention. During implementation, the shuttle car for dense storage 4 rotatable sprocket wheels 2 are symmetrically installed on the vehicle frame 1 of the vehicle, and eccentric shaft holes 3 are all produced on each sprocket wheel 2 (such as figure 1 As shown), install the roller shafts of the intensive storage shuttle on the eccentric shaft holes of the sprockets respectively, and at the same time make the relative position of the center of the eccentric shaft hole 3 of each sprocket relative to the horizontal line passing through the center of its ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com