Fluid stream hydrodynamic separator with high flow bypass

A technology of flow rate and flow flow, applied in the field of hydraulic separator unit, which can solve problems such as layout blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

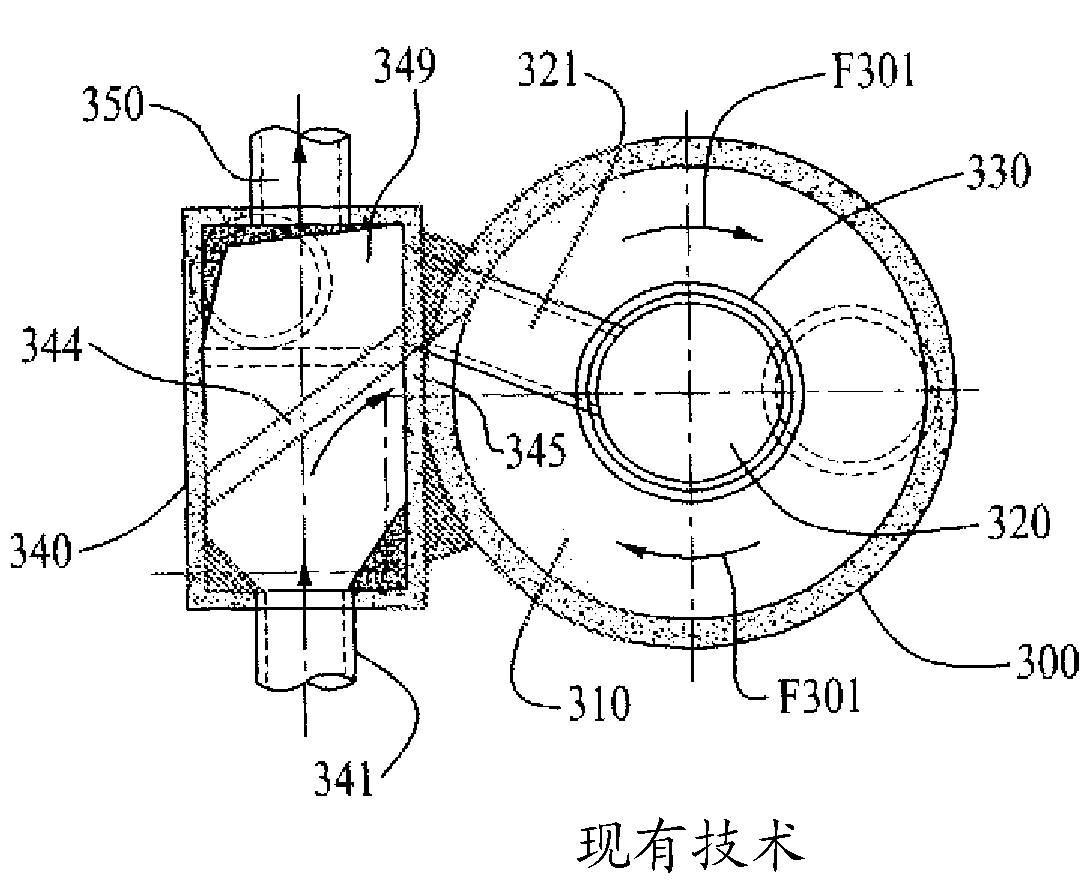

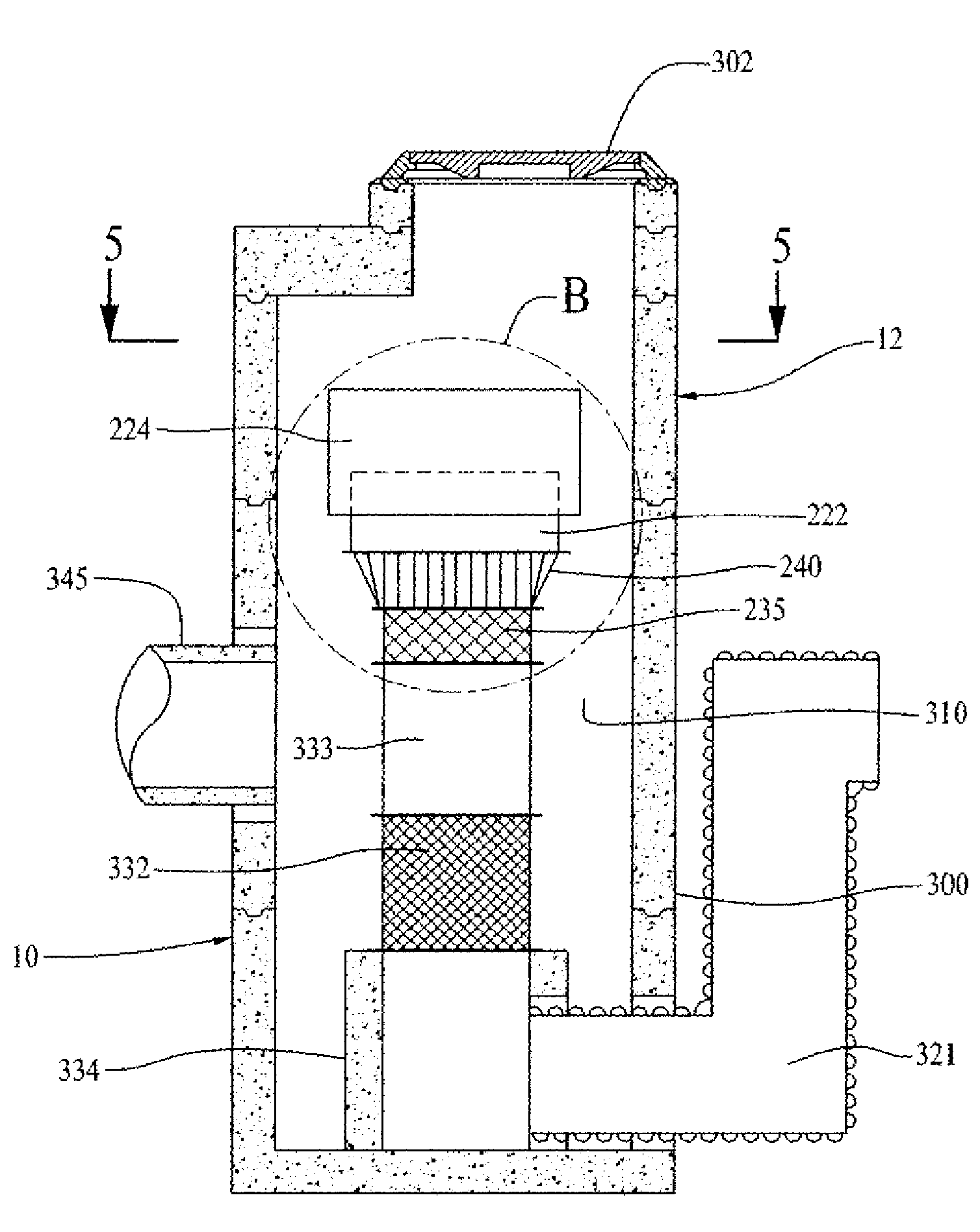

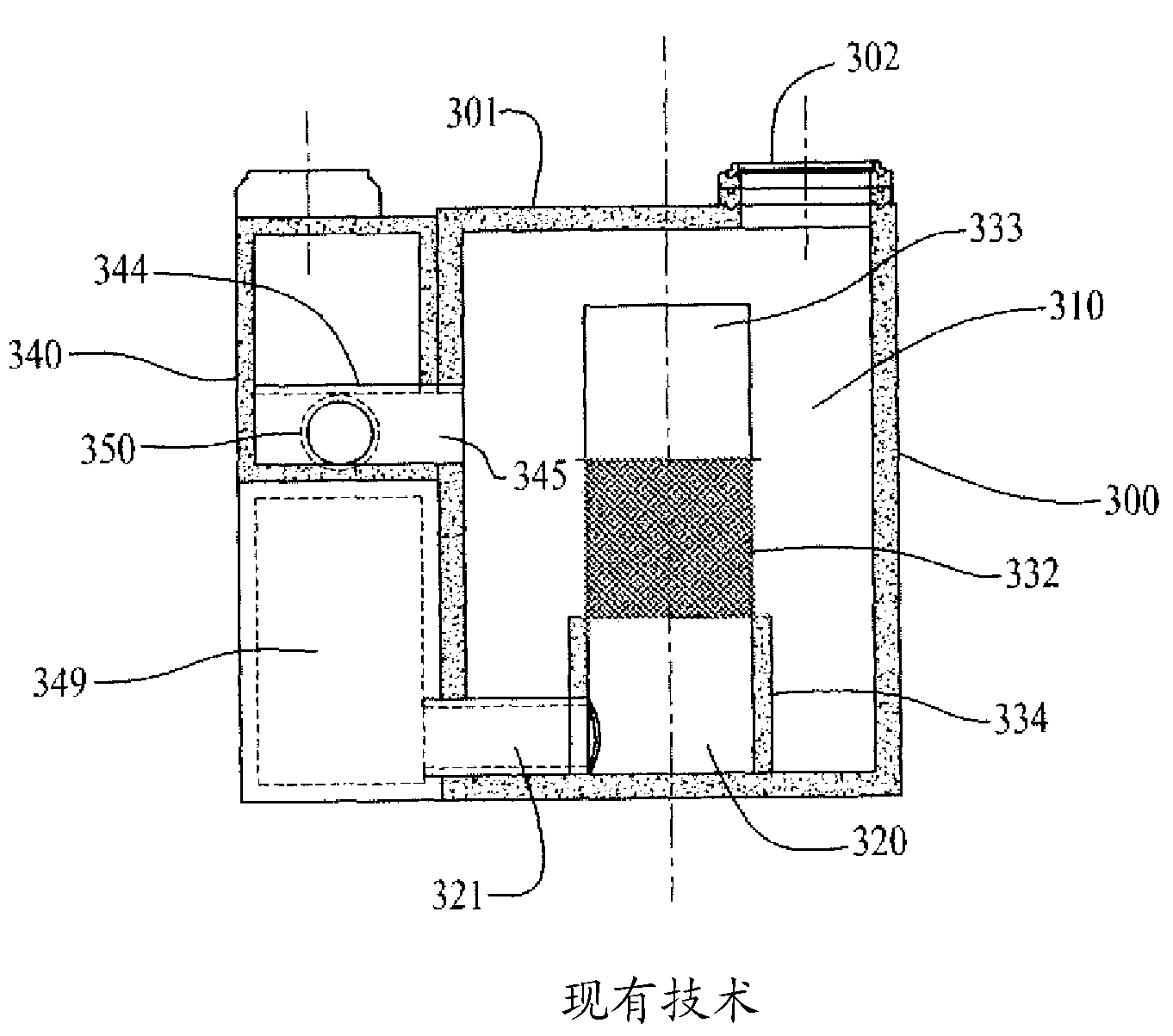

[0018] A hydraulic separator is described and illustrated herein for use in separating solid matter from liquid surface water streams, such as urban and industrial storm runoff containing waste materials. This structure is typically used to separate debris from an incoming stream before more delicate processing can be applied to the flowing stream. separator 10 (shown in Figure 3-6 Middle) includes an upper extension 12, referred to herein as the Quad Bypass Tower. This construction is a prior art structure (eg figure 1 and 2 shown in ) is an improvement over that.

[0019] refer to figure 1 , the barrier plate 333 comprises a solid walled hollow cylinder mounted on top of the main screen cylinder 332 which can be made porous by expansion, perforation, stamping, slotting or otherwise to Sieve material is provided. The rise of the top of this cylinder is set such that there is a relative height of about 1 to 2 feet above the desired water rise for flow across the bypas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com