Servo valve body assembling tooling

A technology for assembling tooling and servo valves, which is applied in the field of tooling bodies for assembling servo valve bodies and tooling equipment for hydraulic components. It can solve problems such as low assembly efficiency, loss of precision of parts, and failure to form assembly specifications, achieving convenient operation and accurate positioning. , the effect of smooth assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

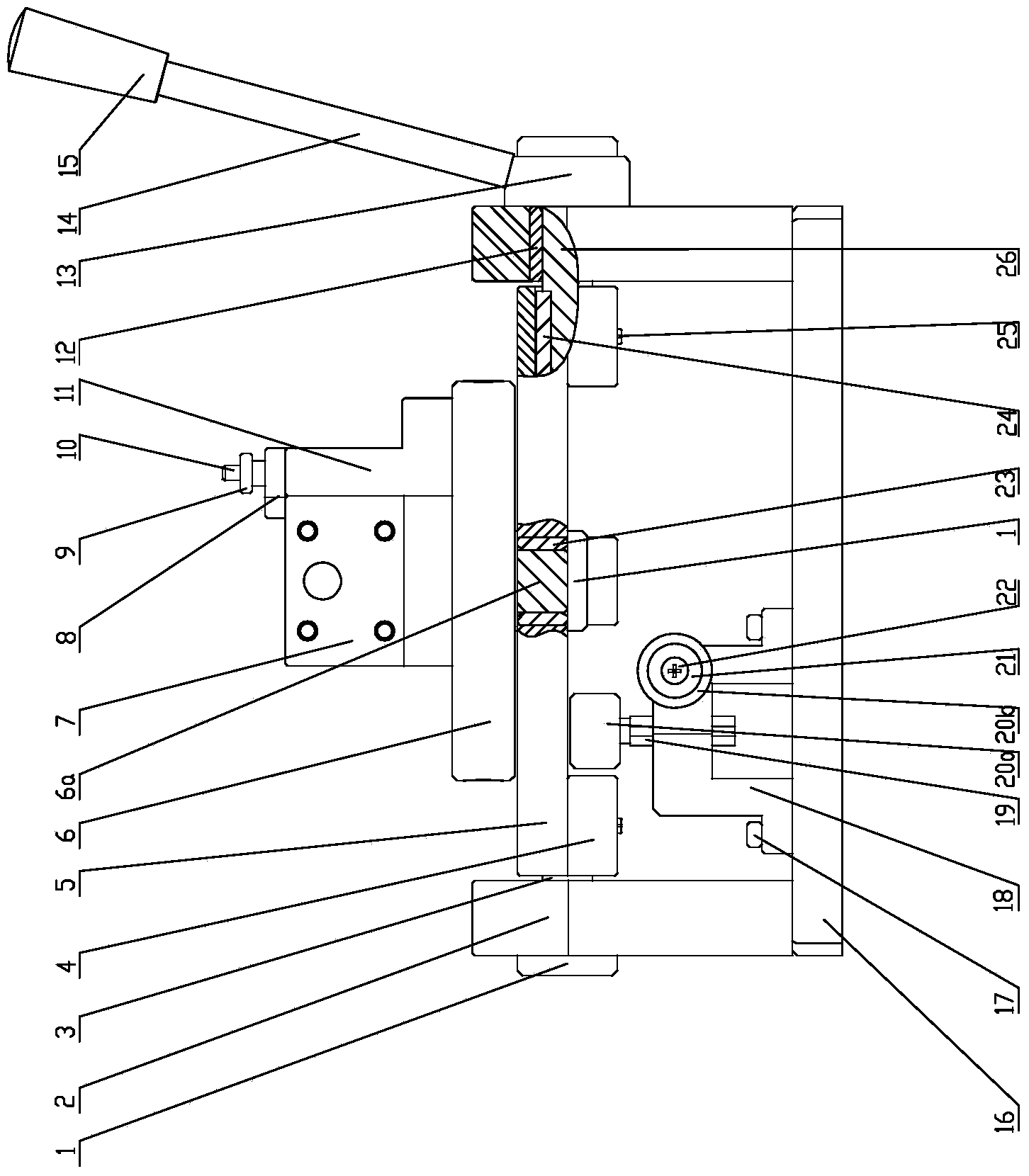

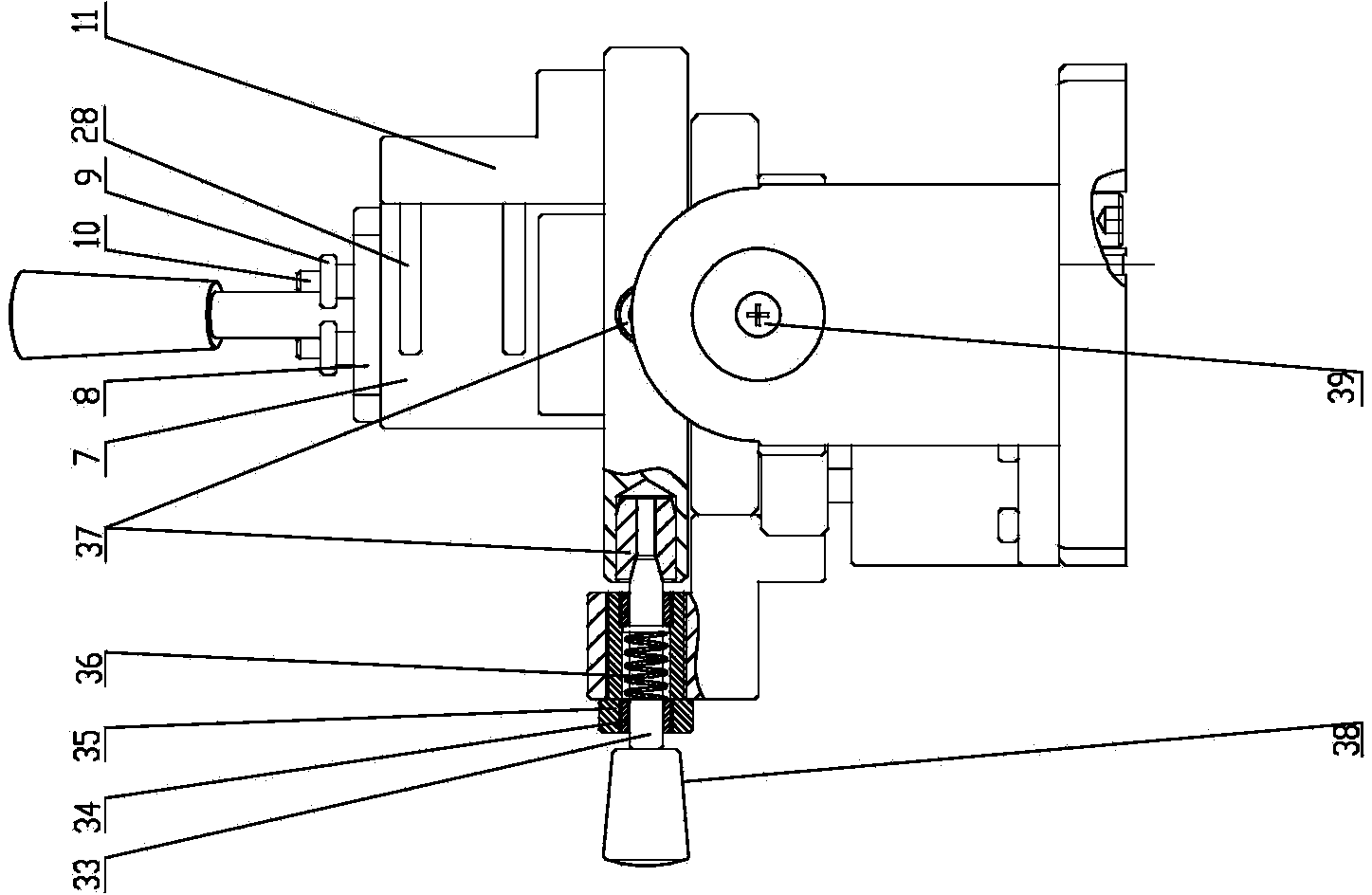

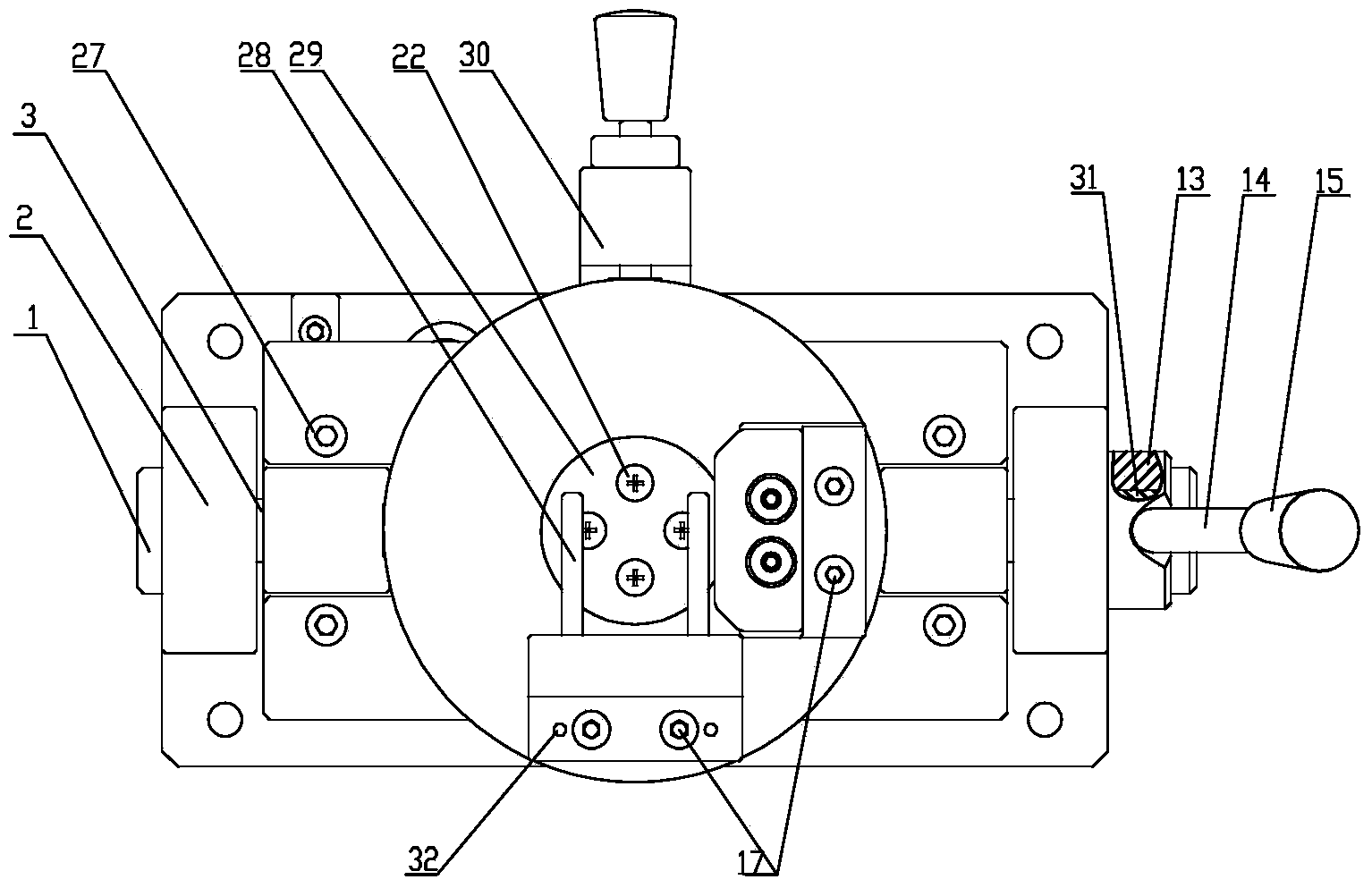

[0019] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0020] As shown in the figure: the servo valve body assembly tooling in the embodiment is mainly composed of a locking cover (1), a bracket (2), a left shaft (3), an upper sub-plate bracket (4), an upper sub-plate (5), and a turntable (6), four-pin positioning vertical plate (7), pressure plate (8), knurled lock nut (9), studs (10), vertical positioning plate (11), copper sleeve (12), handle cover (13), handle shaft (14), long handle (15), main body bottom plate (16), screw (17), figure-of-eight locator (18), lock nut (19), vertically adjustable bumper bar (20a) , horizontally adjustable bumper (20b), nylon bumper (21), cross-recessed countersunk screw (22), copper sleeve (23), key (24), set screw (25), right shaft (26 ), countersunk head screw (27), locating pin (28), nylon washer (29), locating plate (30), key (31), conical pin 32, locating cone pin (33), sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com