Capping lifting mechanism, capping device and capping machine

A lifting mechanism and capping technology, which is applied in the directions of tightly capping containers with lids, packaging, conveyors, etc., can solve problems such as the impact of drug quality, the impact on bottle delivery efficiency, and the easy occurrence of bottle frying, so as to avoid pollution problems and ensure The effect of bottle feeding efficiency and improving operation convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

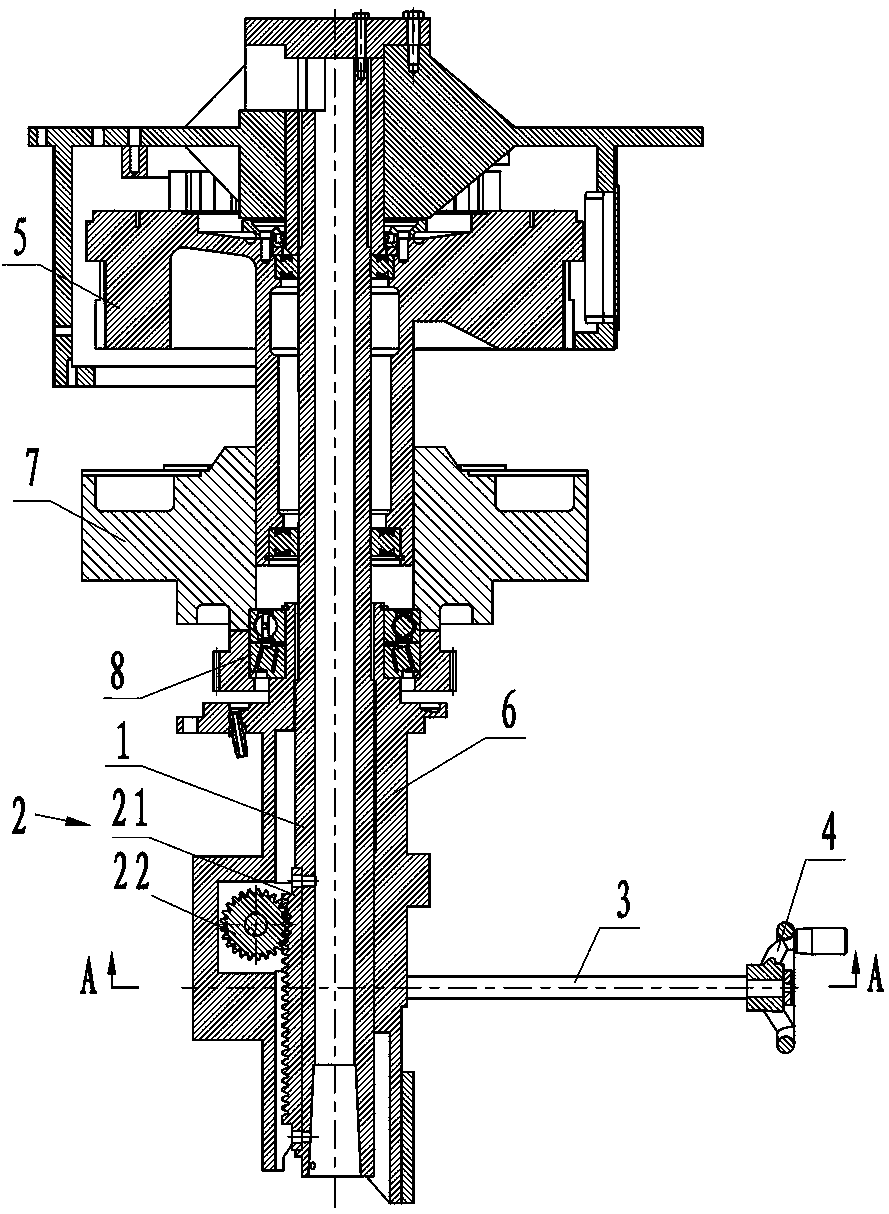

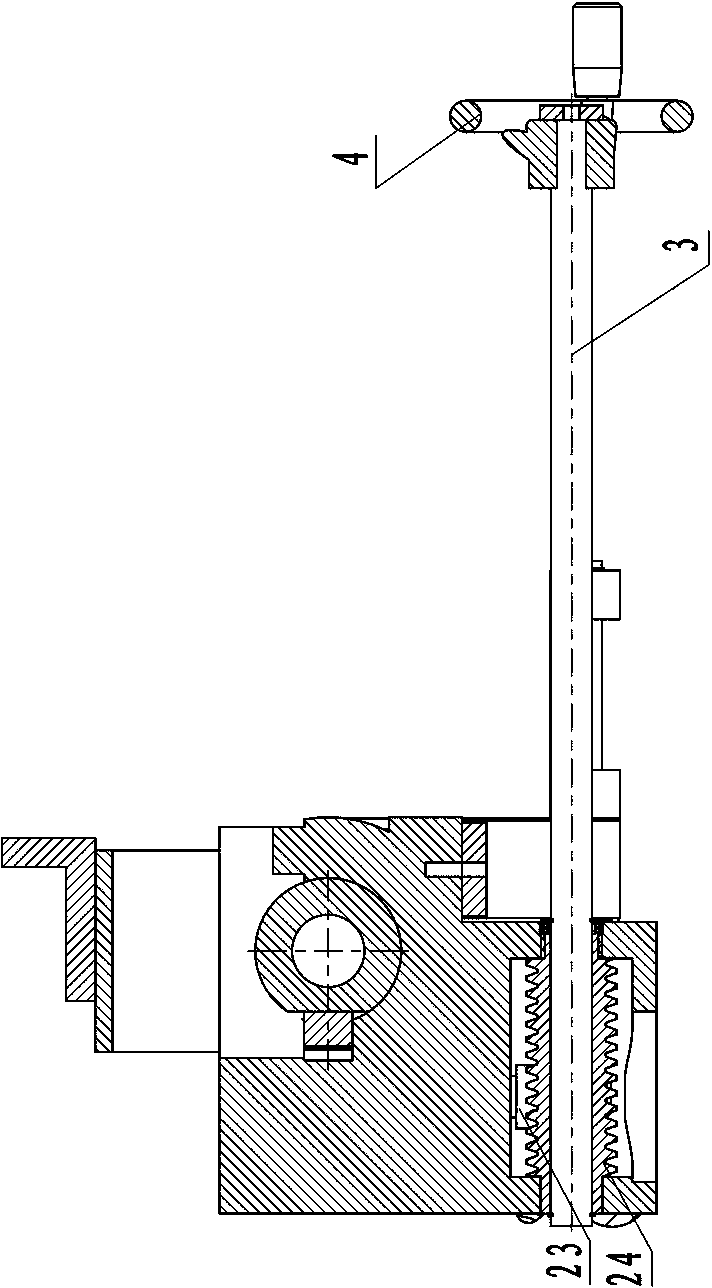

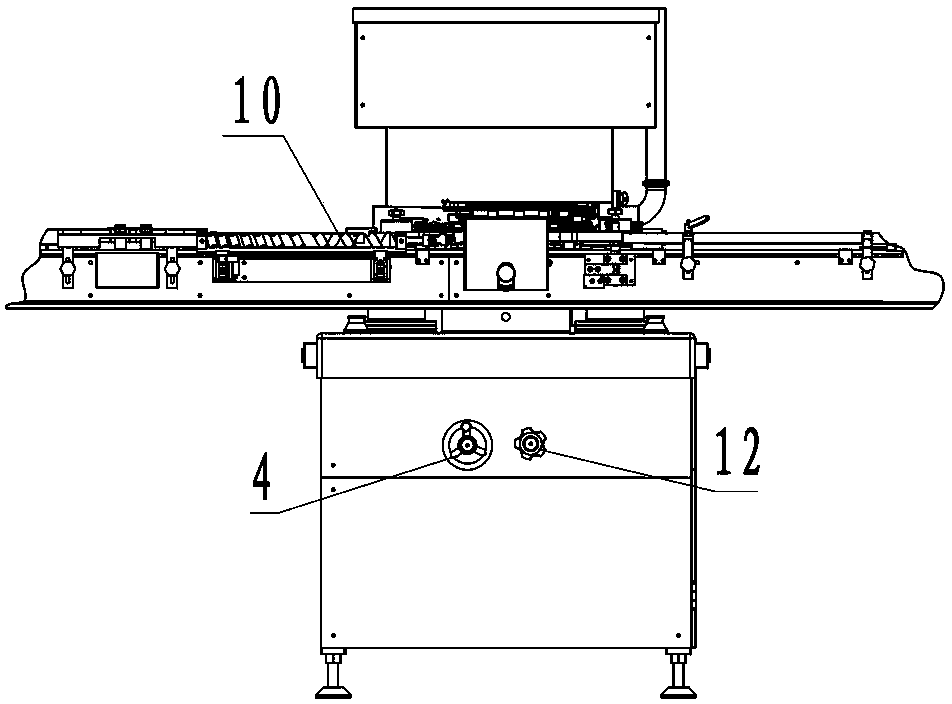

[0029] figure 1 , figure 2 It shows an embodiment of the capping and lifting mechanism of the present invention, which includes a capping main shaft 1 and a lifting assembly 2 that drives the capping main shaft 1 to move up and down. 23. The worm 24 and the rack 21 are fixed on the capping main shaft 1, the gear 22 and the worm wheel 23 are coaxially fixed, the worm wheel 23 is driven by the worm 24, the worm wheel 23 drives the gear 22, and the gear 22 drives the rack 21 to drive the capping The main shaft 1 moves up and down to realize the lifting adjustment of the capping part 9. The structure is simple and compact; since the worm gear and the rack and pinion have self-locking functions, the self-locking parts of the lock nut are omitted, which effectively avoids the need to adjust the capping main shaft. 1 height position, the cumbersome process of adjusting the position of the main shaft by rotating and loosening the lock nut, through the cooperation of the worm gear an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com