Zero degree dry red drink and its preparation process

A preparation process and beverage technology, applied in the field of beverage processing, can solve the problems of increased acidity, loss of taste of wine, weakening of mellow and astringent feeling, zero-degree dry red wine loses the taste and flavor of dry red wine, etc., to achieve enhanced astringency and good taste , the effect of coordinating the acidity of sugar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for making dry red wine base after dealcoholization, using raw dry red wine as raw material, distilling at -0.1MPa, 56-58°C for two hours to remove ethanol in the dry red wine Obtain wine base afterward, the alcoholic strength of described wine base is no more than 0.5%.

Embodiment 2

[0027] A preparation process for zero-degree dry red drink, comprising the steps of:

[0028] A. Dealcoholization of raw wine: take dry red wine raw wine as raw material, distill for two hours at -0.1MPa, 56-58°C, remove the ethanol in the dry red wine raw wine to obtain the wine base, the wine base The alcohol content does not exceed 0.5%;

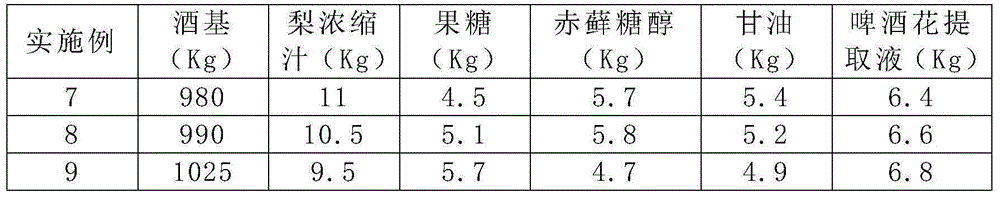

[0029] B. Wine body taste adjustment and wine body aroma adjustment: add pear juice concentrate 8-12Kg, fructose 4-6Kg, erythritol 4-6Kg, glycerin 4-6Kg, hop extract 6-7Kg in 1000Kg wine base, Adding an appropriate amount of wine body aroma regulator to the wine base; thus making a zero-degree dry red drink;

[0030] C. Filling: hot-pack the zero-degree dry red drink that has been adjusted for the taste and aroma of the wine body into bottles and cans at a temperature of 86-88°C, and cool down immediately after the hot-filling is completed.

[0031] Wine body aroma regulators include redwineflavor (300164), wineflavorliqw / s (354485) pro...

Embodiment 3

[0033] The process steps of this embodiment are basically the same as in Example 2, except that in step B, 10Kg of pear juice concentrate, 5Kg of fructose, 5Kg of erythritol, 5Kg of glycerin, and 6.5 kg of hop extract are added to the 1000Kg wine base. Kg.

[0034] The preparation method of the hop extract is as follows: soak 1 g of hops in 100 g of water, boil for 30 minutes, and filter and remove the slag after cooling to obtain the hop extract; the sugar content of the pear concentrated juice is 70.18wt% , acidity (calculated as citric acid) is 1.31wt%, light transmittance (625nm) is 98.4%, chromaticity (440nm) is 65.3, turbidity (NTU) is 0.477.

PUM

| Property | Measurement | Unit |

|---|---|---|

| translucency | aaaaa | aaaaa |

| turbidity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com