Antibacterial agent and preparation method thereof

A technology of antibacterial agent and phenoxyethanol, which is applied in the field of antibacterial agent and its preparation, can solve problems such as residual odor, achieve good water absorption and softness, good bactericidal and bacteriostatic effect, and fast and good bactericidal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Add 40kg of phenoxyethanol, 20kg of dioctadecyldimethylammonium bromide, and 8kg of hyaluronic acid into a mixed solution of 5kg of ethylene glycol and 10kg of polyethylene glycol with a relative molecular weight of 300, and pass through a frame Stir the mixer at 60°C for 15 minutes, keep warm for 2 hours, cool to room temperature, and set aside;

[0029] (2) Add 2 kg of triolein to the product of step (1), and mix evenly at room temperature to obtain an antibacterial agent.

[0030] The performance test results of the prepared antibacterial agent are shown in Table 1.

Embodiment 2

[0032] (1) Add 50kg of phenoxyethanol, 25kg of dioctadecyldimethylammonium bromide, and 10kg of hyaluronic acid into a mixed solution of 10kg of ethylene glycol and 15kg of polyethylene glycol with a relative molecular weight of 500, and pass through a frame Stir the mixer at 90°C for 30 minutes, keep warm for 3 hours, cool to room temperature, and set aside;

[0033] (2) Add 5 kg of triolein to the product of step (1), and mix evenly at room temperature to obtain an antibacterial agent.

[0034] The performance test results of the prepared antibacterial agent are shown in Table 1.

Embodiment 3

[0036] (1) Add 60kg of phenoxyethanol, 30kg of dioctadecyldimethylammonium bromide, and 5kg of hyaluronic acid into a mixed solution of 8kg of ethylene glycol and 12kg of polyethylene glycol with a relative molecular weight of 300, and pass through the frame Stir the mixer at 70°C for 20 minutes, keep warm for 2 hours, cool to room temperature, and set aside;

[0037] (2) Add 3kg of glycerol trioleate to the product of step (1), and mix evenly at room temperature to obtain an antibacterial agent.

[0038] The performance test results of the prepared antibacterial agent are shown in Table 1.

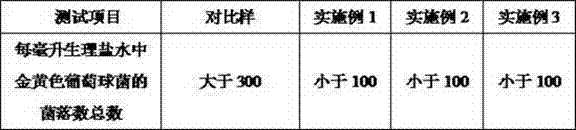

[0039] Table 1

[0040]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap